Stainless Steel WElding tips part 2 - pulse settings and purge tips

In the part 1 segment of this series, I welded some outside corner joints and talked about using backing and chill bars and also some tips for maintaining the stainless properties of stainless steel.

For part 2, there are several threaded nipples to be welded along with some small end caps that will require argon purge.

That provides a good example for talking about pulse tig settings and also some argon purge tips.

click here to watch the part 1 video on stainless steel tig welding tips

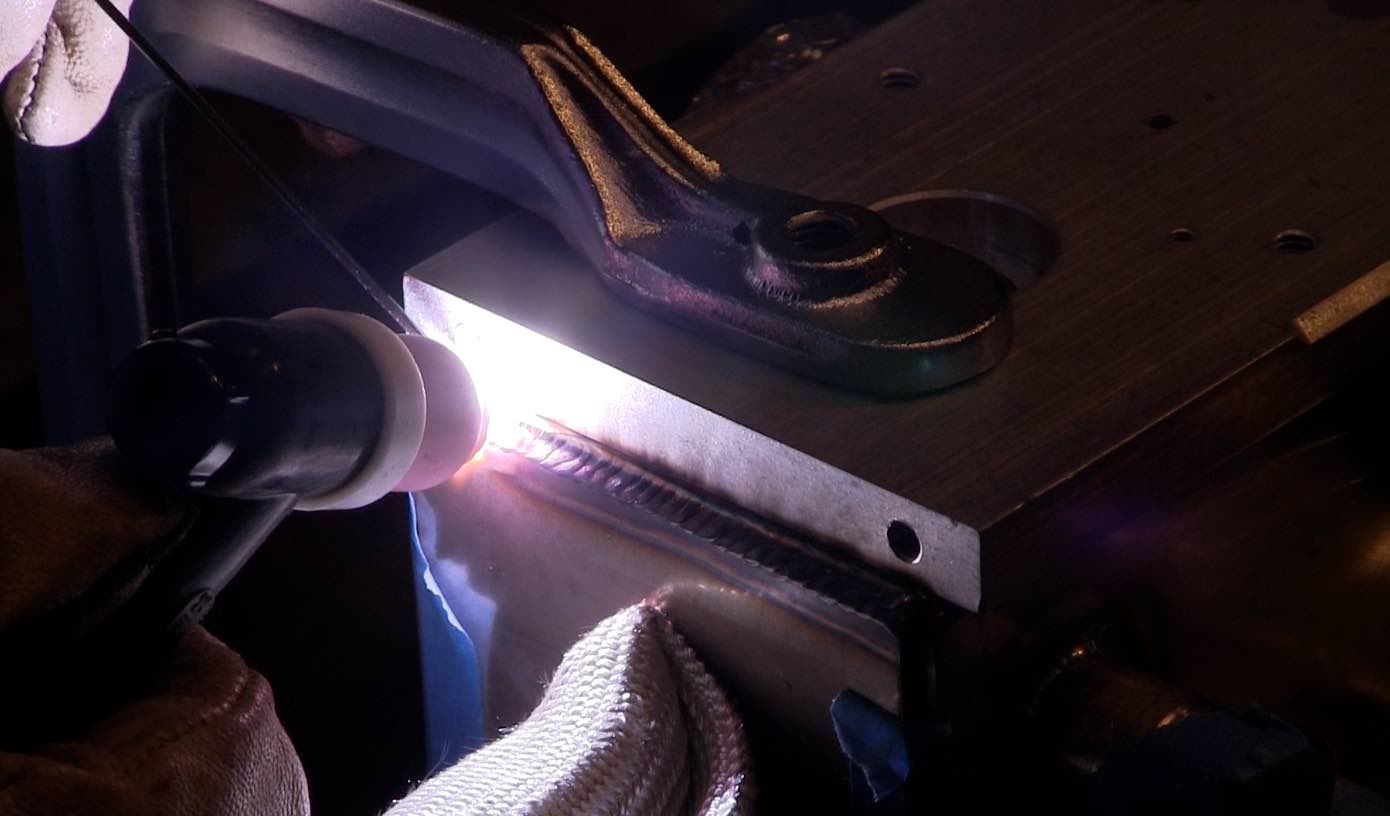

Before I even get into the tips and tricks in this video, I want to call attention to how I was able to prop easily right next to the weld using my Tig Finger™ product. Thats all I am going to say.

...Introducing the New WeldMonger Challenger TIG kit that includes the most frequently used Cups.

Using pulse tig settings and aluminum backing to limit heat input

Using pulse does not always reduce heat input.

Did you get that? Let me say it again and let it sink in because it goes against the claims of a lot of welding machine manufacturers.

Travel speed is one of the biggest factors that either puts more heat into a part...or less.

So if pulsing slows down your travel speed, using pulse tig can actually increase heat input.

But I think you can readily see in this video, that the pulse settings I used increased travel speed and therefore ...did actually reduce overall heat input.

learn more about the ck mt200 acdc

I used a CK worldwide mt200 tig welder for this stainless steel welding project...

Settings of 1 pulse per second and 20% background current really worked very well for these threaded nipples.

I think the pulse current on time on this CK mt200 welder is fixed at around 40-50%.

I used aluminum backing for all the 1/2" threaded nipples by using a piece of 1/4" thick aluminum angle clamped to the side where all the nipples would be welded.

This one thing helped tremendously in speeding up the cooling rate and pulling out heat to avoid distortion and discoloration.

The pulse settings also helped a lot because they helped increase my travel speed and travel speed is one of the main things that contributes to overall heat input.

Stainless steel welding purge tips

Argon is the most frequently used purge gas for tig welding stainless steel.

Sometimes nitrogen can be used but argon is more commonplace.

Argon is heavier than air and so it helps to think of it as water when you are contemplating where to make vent holes.

Sometimes hard caps and plugs are used to seal off openings but most often tape is used.

So making vent holes in the tape in the right places is key to achieving a good high purity argon purge.

notice the water and milk jug demonstration in the video.

Without a vent hole in the right spot, and good purge would not happen.

Also , its worthwhile to note that because water contains oxygen, if you have even a drop or two of water inside the area you are trying to purge, you will not get a high purity purge until the water is completely gone.