6011 rods (the best video page on the net showing 6011 stick welding)

- HOME

- STICK WELDING

- 6011

Using 6011 3/32" off 115 volt power for a Gate repair

6011 Rods for A quick project

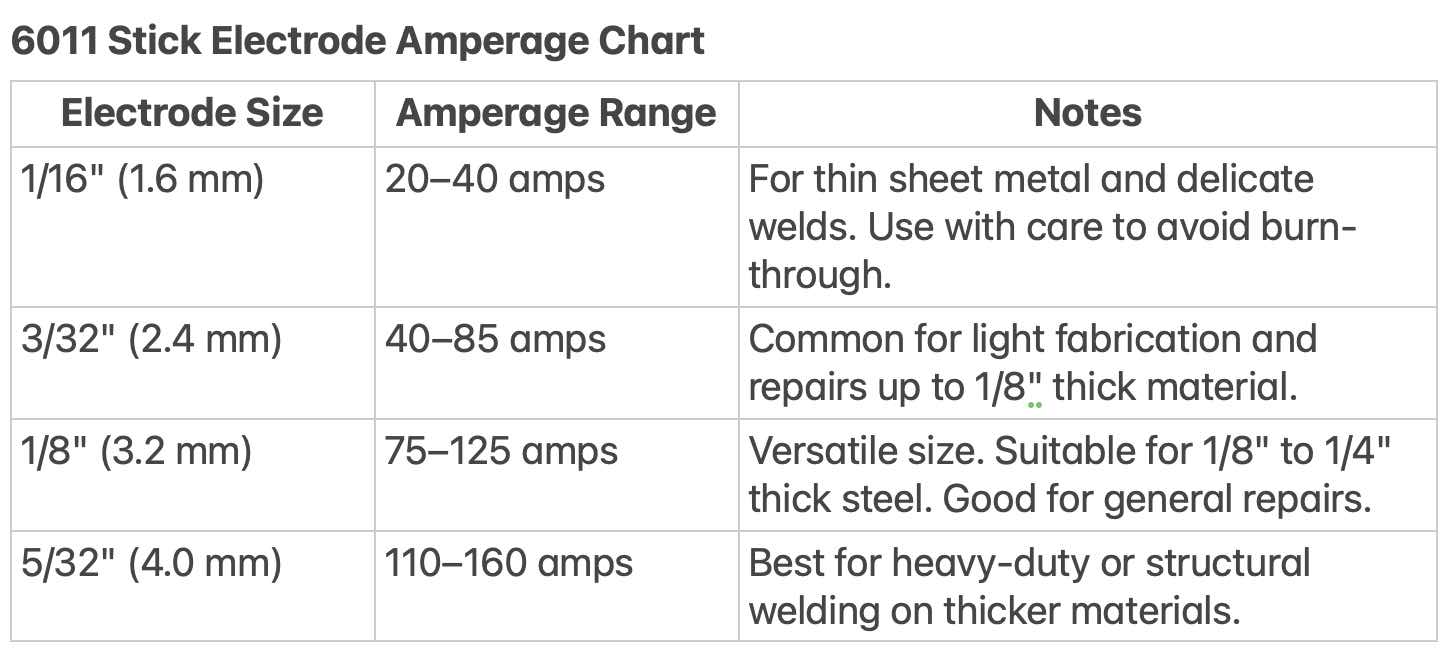

6011 Amperage Chart

Why Did I use 6011 and a buzz box to build a Dolly?

A few weeks ago, I was under the gun to move all my equipment out of the shop I have been working in for about 3 years.

My

machinist friend had a old Dake cold saw that was not on casters and

was concerned about how he was going to move it around his shop once we

loaded it on a trailer.

So he asked me to make a temporary dolly for the cold saw.

Now

mind you, we only had a day or two before we had to be completely

vacated out of this building and I had a bunch of work to do so I didnt

have much time to spare in building this dolly.

And pretty much ,

the only material left in the shop was a stack of of 1-1/2" square

tubing and some 1-1/4" angle. Both too lightweight to hold a 1000 lb

cold saw.

So we thought if we doubled them up, and added a cross brace, that would do the trick.

Another

thing I had to work around was the fact that we had already moved all

the mig welders and welding tables out the shop. So the only welding

machine left was a Lincoln tombstone buzz box. (AC welder).

But

that is not a big problem, a Lincoln buzz box is perfectly fine for a

quick fabrication job like this. Mig would have been quicker and better

looking, but Stick was the only option today.

For fabrication jobs like this dolly, I usually choose 6011 stick rod.

And Here is why...

E6011 rods are all position welding rods AND...can weld downhill very well.

Framing

jobs like this dolly often have outside corner joints and being able to

weld those downhill really speeds things up because the same amperage

works for downhill and what you use for flat and horizontal welds.

.....AND 6011 rods will easily penetrated thru rust, mill scale, dross, paint, or pretty much anything.

Several years ago, I built a metal rack for the same friend out of some Square tubing and heavy wall angle. All the metal was free but had light rust on it. The angle iron was 4 inch leg with 1/2" leg thichness and the square tubing was 4 inch but only about 3/16" wall thickness.

But it was same situation, no mig welders in the shop yet, only the same lincoln buzz box.

We had an old box of 5/32" 6011 rods and a buzz box and a cutting torch. And we built a set of christmas tree style metal racks that are still holding at least a ton of metal to this day.

Actually, thinking back, it was probably the best way we could have done it. Those 5/32" 6011 rods set good and hot at around 160 amps will really dig whether you weld downhill or flat or horizontal.

6010 rods are used a lot for pipe welding and especially for welding a root pass in a pipe joint.

asme codes usually require uphill welding but there are other codes like API codes that require downhill using 6010.

6011 rods are very similar to 6010

... and are designed to weld either on DC or AC...with a stabilizer in the flux to allow for some smooth welding on AC (alternating current)

...6010 rod are DC only.

The welding technique for a root pass in pipe uphill

is typically called a whip and pause technique for uphill. That means

you move the electrode in and out of the puddle to control heat buildup

and the size of the keyhole ( keyhole is a term used to describe the

area melted away as you weld a root pass...its shaped like an antique

keyhole).

For downhill root passes in pipe, the technique is a bit

different. The machine is set at an amperage where you can just jam the

rod in and it wont stick. If thing are set right, you hardly even see

an arc on the outside of the pipe.

Other passes are also welded

downhill using API code and are often X rayed to verify quality. So if

pipeline welds are made downhill and are even subjected to Xray.. for

that reason we know that good welds can be made downhill using E6010 or

E6011.

(I made a point to address this because there is always someone willing to argue that downhill welding is no good.)

And

for fabrication, the welding technique can be whip and pause, or small

circles, a slight weave, even a drag motion works ok if you want a

slightly convex bead.

There is really no wrong way to run a E6011 rod

in my opinion. You just have to realize 6011 rods are a deep

penetrating rod so you kinda have to watch for undercut...especially at

the top of a horizontal bead.

For general fabrication, a mig

welder makes things go faster and look better. But when all you have is a

buzz box, you can still get the job done.