2019 DVD is my Best Ever!

This is my best DVD ever!

Read what others are saying…

Excellent videos - again!

George on Mar 15, 2020

Jody

has done it again, a fantastic set of welding videos that really help

up your game. What I really appreciate is all the detail provided so you

can practice and replicate what he has done. And the best is - no BS,

no drama, just straight forward invaluable welding help. Excellent!

Always outstanding!

Steven on Mar 06, 2020

Over

the years, I've bought a number of things from Mr. Collier's store, and

never has anything been less than first class. This man knows what he

is talking about, and the instructional material simply can't be beat. I

am sure I will do business in the future.

Click here or the picture below

I failed my first welding test…

why am I telling you this?

* Because I remember what it was like to fail that welding test when I was so hoping to get that job.

* And because my new DVD is has lots of 6010 pipe test videos and if I had videos like this back then, I would have passed that first test.

* And I just want to help people succeed

Each year I get my son to put all the previous years videos on a 4 disc DVD set.

And This DVD set is my best one yet.

So this video is a quick preview showing the DVD playing on a big screen TV in my living room.

And let me tell you, if you have been only watching my youtube videos on a phone or computer, you will be amazed at the details you see on a big TV.

Many viewers comment that they can see the details of the arc and puddle better than they can under their own welding hood.

Not only are there lots of videos on TIG welding carbon, stainless, and aluminum…and even titanium. … and also MIG welding uphill

But there are several 6010 root pipe test videos…both uphill and downhill that all have crisp arc shots along with Pro Tips that will absolutely help you pass a welding test, get a better job, get a raise., get a promotion, help you feed your family.

The 6010 root videos alone are worth way more than the cost of the entire 4 disc set.

There is no substitute for welding school but the videos on this DVD will flat out enhance your learning experience even if you are in welding school and have a great instructor.

Its hard to see over an instructors shoulder sometimes…especially if there are 3 other students crowding in trying to watch.

With this DVD you can watch over and over. Pause…rewind…play in slow motion…and even zoom in to see all the details you cant see while looking over a shoulder.

And you can do it out in the shop with no internet.

I am laying it on heavy because I would be doing you a disservice by not trying hard enough to get you to pull the trigger.

I believe in it that much.

Invest in yourself!

What is the one thing that makes all the difference in a good welding video?

Is it awesome graphics? ripple dissolve transitions between scenes? A deep radio voice on the narration?

Not for me.

I have purchased several welding DVD's for myself and none of that stuff ever impressed me.

How about clear shots of the welding puddle and arc along with plain talk explaining what is going on?

Thats what makes for a good welding video.

If I can see a good arc shot along with an explanation and some basic machine settings, thats all I need.

I talked with a welding instructor recently who ordered several hundred dollars worth of welding training videos from an educational website.

The videos were horrible...He was so disappointed when he first watched them because of the college professors monotone narration and lousy arc shots. His students hated them too so he put them in a drawer.

You wont have that problem with this Welding DVD.

I am no College Professor...No PhD here

I am a welder.

I dont use fancy terms, and I hate overly complicated explanations of anything.

It took 4 DVD discs to fit all these videos.

So whats on these 4 Discs?

scroll down and check it all out.

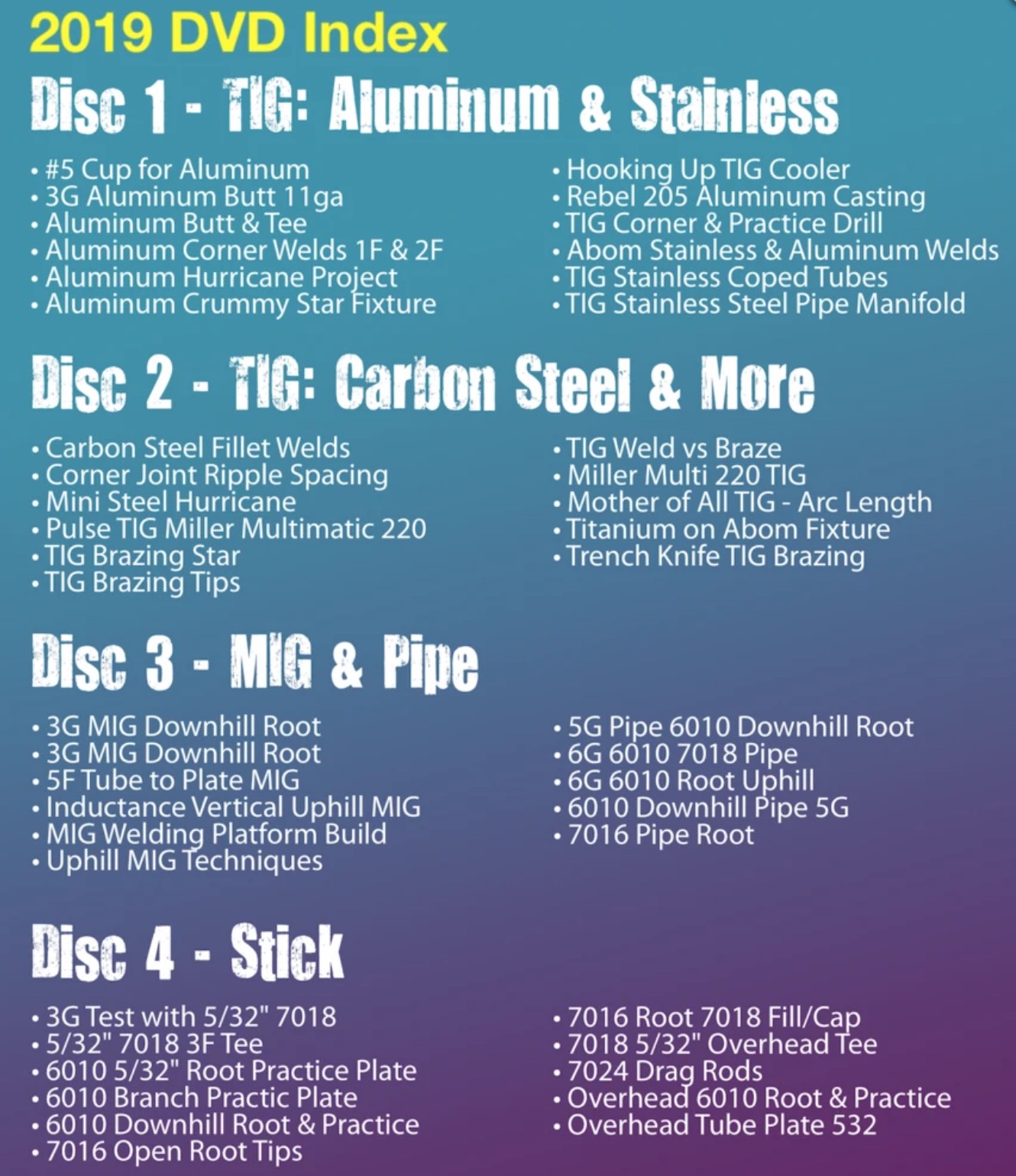

Disc 1 - TIG: Aluminum & Stainless

- #5 Cup for Aluminum

- 3G Aluminum Butt 11ga

- Aluminum Butt & Tee

- Aluminum Corner Welds 1F & 2F

- Aluminum Hurricane Project

- Aluminum Crummy Star Fixture

- Hooking Up TIG Cooler

- Rebel 205 Aluminum Casting

- TIG Corner & Practice Drill

- Abom Stainless & Aluminum Welds

- TIG Stainless Coped Tubes

- TIG Stainless Steel Pipe Manifold

Disc 2 - TIG: Carbon Steel & More

- Carbon Steel Fillet Welds

- Corner Joint Ripple Spacing

- Mini Steel Hurricane

- Pulse TIG Miller Multimatic 220

- TIG Brazing Star

- TIG Brazing Tips

- TIG Weld vs Braze

- Miller Multi 220 TIG

- Mother of All TIG - Arc Length

- Titanium on Abom Fixture

- Trench Knife TIG Brazing

Disc 3 - MIG & Pipe

- 3G MIG Downhill Root

- 3G MIG Uphill Root

- 5F Tube to Plate MIG

- Inductance Vertical Uphill MIG

- MIG Welding Platform Build

- Uphill MIG Techniques

- 5G Pipe 6010 Downhill Root

- 6G 6010 7018 Pipe

- 6G 6010 Root Uphill

- 6010 Downhill Pipe 5G

- 7016 Pipe Root

Disc 4 - Stick

- 3G Test with 5/32" 7018

- 5/32" 7018 3F Tee

- 6010 5/32" Root Practice Plate

- 6010 Branch Practic Plate

- 6010 Downhill Root & Practice

- 7016 Open Root Tips

- 7016 Root 7018 Fill/Cap

- 7018 5/32" Overhead Tee

- 7024 Drag Rods

- Overhead 6010 Root & Practice

- Overhead Tube Plate 532

visit the weldmonger store to learn more about the 2019 welding DVD