Stick Welding ...kicking it Old School...

For welding in Wind, Rain, in the Mud, in a ditch, Stick Welding Still Rules

check out this article and video on hydrogen embrittlement from welding

Did you know we have a stick welding course at welderskills.com with over 40 short concise videos from running your first bead to passing a 6G pipe test?

You can take a free 7 day test drive and have full access to all our courses.

TIG, MIG, Stick, Pulse Spray, Dual shield flux core.

Invest in yourself today and take the free test drive.

See Stick Welding projects my forum members are talking about

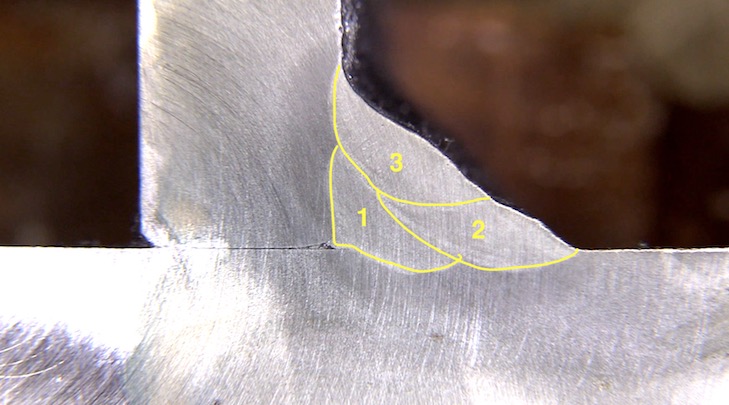

read more about stick welding a multipass fillet

Padding beads in horizontal position with 7018

Multipass tee joint 2f with 7018

Stick welding has been around a very long time. In fact, it was the late 1920's when Lincoln introduced the first flux coated electrode (before that bare wire electrodes were used).

The flux coated electrode was a major breakthrough and made stick or "arc welding" a very dependable and robust process.

While some think its nearly obsolete, Stick or "shielded metal arc welding" (SMAW) continues to be used for quality welding in construction of buildings, bridges, pipelines, and maintenance and repair welding.

It just works.

What is a stick welder good for?

A stick welder is the simplest and most inexpensive way to get started welding and in the hands of someone with even minimal experience, is a very useful thing,

Thats why practically every old farmers barn shop had a buzz box in the corner.

You can weld carbon steel, cast iron, stainless steel, and even aluminum.

Even thin sheet metal can be welded using small 1/16" electrodes like 6011 or 6013 available at harbor freight or amazon, provided your stick welder has a low enough amperage range.

Is stick welding MIG or TIG?

Stick welding is neither mig or tig.

It has been around way longer and in certain situations, like welding outdoors in the wind, can be a better choice than mig or tig welding.

Mig and tig welding use a shielding gas to protect the molten puddle…while stick welding electrodes have a baked on flux that becomes part of the weld puddle and protects it from the atmosphere.

Is stick welding stronger than MIG?

The weld metal itself is equally strong with stick and mig…but sometimes with short circuit mig, you can get poor penetration.

In those instances, stick welding can definitely be stronger than mig.

Is stick welding good for beginners?

There is a perception that MIG welding is the easiest type of welding to learn for beginners because of the way the wire feeds into the puddle without the welder needing to constantly feed the electrode to maintain a proper arc length.

Aside from that one thing, stick welding is a great way for beginners to learn to weld.

After a day or two of learning the basics of feeding the electrode and how not to stick the rod, stick welding can be just as easy to learn as mig welding or flux core.

Advantages:

what is an advantage of using shielded metal arc welding?

With shielded metal arc welding, the one main advantage is that since the electrode has a baked on flux, no external shielding gas is needed, And that makes welding outdoors in windy or rainy conditions is possible.

Another advantage is the stick welding machine itself is simpler and typically less expensive than tig or mig machines.

Positions:

what positions can shielded metal arc welding be performed in.

Shielded metal arc welding aka Stick welding can be used to weld in all positions but the right rod must be used.

There are a few rods that are not designed to be used in all positions.

For example, a 7024 electrode is only designated for flat and horizontal positions.

A number 1 in the second to last number of a stick welding electrode indicates that it can be used in all positions. Examples, 6010, 6011, 6013, 7014, 7018

Polarity:

what polarity is used for smaw.

Different rods sometimes have certain polarity recommendations from the manufacturer , but as a rule, all polarities can be used for stick welding which is also known as shielded metal arc welding or smaw for short.

Old AC stick welding machines are sometimes called buzz boxes because of the noise they make when under load.

Some stick electrodes will not perform well on AC but most will perform well using DCEP reverse polarity.

Disadvantages:

what are the disadvantages of shielded metal arc welding.

Some disadvantages of shielded metal arc welding are:

- Stick welding is usually slower than wire fed welding processes like mig and flux core.

- Not as good for really thin metals as tig

- Spatter and slag needs to be removed after welding

stick welding socket welds for a making a lamp

4g overhead stick welding test

3g vertical stick welding test

horizontal weld test 2g using backing

Padding beads with 7018

Tips for buying your first Stick Welder

stick welding rods

Quicky project using 6011 and a buzz box

7024 welding rods

stick welding with a lincoln powermig 350mp and a buzz box

stick / arc welding uphill and more

stick welding pipe using tig for root and 7018 for fill and cover pass

stick welding using 6011 rods video shows tee joint tips using 6011 rods

tig inverters comparison doing tig and stick welding on a mounting bracket The Miller Maxstar 150stl is a tiny but powerful tig inverter that stick welds too.

Video on Lincoln Excalibur 7018 welding rods

I like Old School Stick/ arc Welding for welding outside, welding over mill scale or when the metal is dirty or oily..., over bad tack welds, and even with a fan blowing the smoke away. You cant do that with mig or tig.

Stick welding is what the old timers still call "arc welding".

In the hands of a skilled welder, it really has its advantages. There is no shielding gas to get blown away by the wind, its cheap, its portable , the equipment is really simple. It is very versatile. You can weld different metals simply by changing the rod. The metal doesn’t have to be all that clean. I could ramble on and on but you get the point.

If you are just getting started welding, one of the best deals on the planet is a 200 amp buzz box.

You can find them on craigslist or at yard sales for less than 200 dollars.

They are called buzz boxes because of the sound they make. The cheaper ones only have A/C current but that is all you need to weld all kinds of stuff.

My first buzz box was free. A friend gave me his 30 year old JC Penny buzz box when he got a new Lincoln 225 for Christmas.

It worked great even though the rods tended to stick at first. Once I stuck them and they heated up a bit they started better the second time. Hey that’s why they call it “stick” welding right?

Oh and dont forget the small portable inverter stick welding machines like miller maxstar 150.

there are also plenty of options for multiprocess dual voltage welders that do mig and DC tig in addition to stick at an affordable price

These small multiprocess inverter welders are an extremely portable solution for welding outdoors.

One really good one is the lincoln 210mp

note: many small inverters will not run a 6010 well. But will run a 6011 ok.

so if you need that feature, make sure you get one rated for 6010

A lot of people don’t know about the small diameter rods that are available. You can get 1/16 inch rods that work a lot better on sheet metal than the bigger ones. In fact if you practice a bit, the little rods work almost as well as a mig welder for thin sheet metal. You can order them online from Northern Tool or get them at the welding supply.

Home depot doesn’t carry them.

If you have been having trouble sticking rods with your small stick welder, the small 1/16 rods can be a HUGE help.

For heavier welding a good ole 7018 rod is hard to beat for strength and appearance. A 1/8 inch rod only needs about 100 to 130 amps to run smoothly so a 200 amp buzz box easily handles 130 amps. There have been a lot of welding businesses that started with only a cutting torch and a buzz box. 6011 rods work well on rusty metal and for downhill welding. The ripples are a little rougher and the slag is a little harder to chip, but they penetrate like a mug. For sheet metal, sometimes 6013 small rods work. Sometimes... lots of people love them, But I try to avoid 6013 rods because they trap slag on downhill runs. I just don't like them. Cant really explain it.

A lot of the welding on power plants and paper mills and high rises is still done with stick.

The reason? It works. Its portable, Its reliable and Its proven.

In contrast to mig welding, stick welding has sort of a built in control: you at least have to have the machine hot enough to keep the rod lit. That in itself almost ensures some amount of penetration.

Mig welding on the other hand is infinitely adjustable. The welder is free to set voltage and amperage very low, even on thick metal and the appearance of the finished mig weld is not a good indicator of the quality of the weld.

Think about that the next time you are behind a truck hauling a utility trailer.

I was on interstate 75 in Atlanta a few days ago and a utility trailer came loose and went across a few lanes of traffic. It was ugly.

Here is the link for tig welding using an old stick welder

Electrode Identification System

Mild Steel Electrodes

Mild steel electrodes are identified by a system that uses a series of numbers to indicate the minimum tensile strength of a good weld, the position’s in which the electrode can be used, the type of flux coating, and the types of welding currents.

E6012 The letter E prefixes the number and represents the electrode. The E is used as a prefix for any filler metal that uses electricity to perform a weld.

E6012 The first two or three numbers indicate the minimum tensile strength of a good weld, for example E60XX, E70XX, E110XX. The tensile strength is given in pounds per square inch (psi.). The actual strength is obtained by adding three zeros to the right of the number given. For example, E60XX is 60,000 psi. and E110XX is 110,000 psi.

E6012 Refers to the metal welding position. The number 1,2,3, or 4 to the right of the tensile strength designation gives the position...1= all positions - 2 =horizontal or flat - 3 = flat only - 4 = all positions but vertical down.

E6012 The last number indicates the major type of flux covering and the type of welding current.

0 - DCRP 1 - AC/DCRP 2 - AC/DCSP 3 - AC/DC

4 - AC/DC

5 - DCRP

6 - AC/DCRP

8 - AC/DCRP

DC = direct current

DC/SP = direct current straight polarity

AC =alternating current

DC/RP = direct current reverse polarity

Understanding Electrode Data

Tensile Strength The load in pounds that would be required to break a section of good weld that has a cross-sectional area of one square inch.

Yield point,PSI The point in low and medium-carbon steels at which the metal begins to stretch when stress is applied, after which it will not return to its original length.

Elongation The percentage, a two inch piece of metal will stretch before it breaks.

Charpy V-notch ft.lb. The impact load required to break a test piece of welded metal. This test may be performed on metal below room temperature, at which point it is more brittle.

Alloy Elements and Their effects on Steel

Carbon (c) As the percentage of carbon increases, the tensile strength increases, the hardness increases, and ductility is reduced.

Sulphur (S) It is usually a contaminant and the percentage should be kept as low as possible, below 0.04%. As the percentage of carbon increases, Sulphur can cause hot shortness and porosity.

Phosphorus (P) It is usually a contaminant and the percentage should be kept as low as possible. As the percentage of phosphorus increases, it can cause brittleness, reduced shock resistance, and increased cracking.

Manganese (Mn) As the percentage of manganese increases, the tensile strength, hardness, resistance to abrasion, and porosity all increase; hot shortness is reduced.

Silicon (Si) As the percentage of silicon increases, tensile strength increases, and cracking may increase.

Chromium (Cr) As the percentage of chromium increase, tensile strength, hardness, and corrosion resistance increase, with some decrease in ductility.

Nickel (Ni) As the percentage of nickel increases, tensile strength, toughness, and corrosion resistance increase

Molybdenum (Mo) AS the percentage of molybdenum increases, tensile strength at elevated temperatures and corrosion resistance increase.

Stick Electrode Selection--Choosing the right Stick Rod

Type of Current: Can the welding power source supply AC only, DC only, or both AC and DC?.

Power Range: What is the amperage range on the welder and it’s duty cycle? Different types of electrodes require different amperage settings even for the same size welding electrode.

Type of Metal: Some welding electrodes may be used to join more than one similar type of metal. Other electrodes may be used to join two different types of metal.

Metal Thickness: The penetration characteristics of each welding electrode may differ. Selecting the electrode that will properly weld on a specific thickness of material is very important.

Weld Position: Some electrodes will weld in all positions. Other electrodes may be restricted to the flat and horizontal or vertical positions, or only the flat electrodes will weld on metal that is rusty, oily, dirty or galvanized with sufficient penetration.

No. of passes: The amount of reinforcement needed may require more than one pass. Some welding electrodes build up faster and others will penetrate deeper. The welding slag may be removed more easily from some welds than others.

Temperature: Welded metals react differently to temperature extremes. Some welds become very brittle and crack easily in low temperature service. (when welding in cold temperatures, you should pre-heat the metal, and after the weld is made it should be covered or shielded from the cold to allow it to cool slowly).

Mechanical: Mechanical properties such as tensile strength, yield strength, hardness, toughness, ductility, and impact strength can be modified by the selection of specific welding electrodes.

Distortion: Welding electrodes that will operate on low-amperage settings will have less heat input and cause less distortion. Welding electrodes that have a high rate of deposition (fills joints rapidly) and can travel faster will cause less distortion.

Welding Clean-up: The hardness or softness of a weld greatly affects any grinding, drilling, or machining. Also slag and spatter removal affects the time and amount of clean-up required.

Most Common Steel Stick Welding Electrodes

E6011 The E6011 electrodes are designed to be used with AC or DC reverse polarity currents and have an organic-based flux. They have a forceful arc that results in deep penetration and good metal transfer in the vertical and overhead positions. The electrode is usually used with a whipping or stepping motion. This motion helps remove unwanted surface materials such as paint, oil, dirt and galvanizing. The E6011 has added arc stabilizers which allow it to be used with AC. Using this welding electrode on AC current only slightly reduces its penetration qualities. The weld puddle may be slightly concave from the forceful action of the rapidly expanding gases. This forceful action also results in more spatter and spark during welding.

E6013 The E6013 electrodes are designed to be used with AC or DC, either polarity current. They have a rutile-based flux (titanium dioxide). The electrode has a very stable arc that is not very forceful, resulting in a shallow penetration characteristic. This limited penetration characteristic helps with poor fitting joints or when welding thin materials. Thick sections can be welded, but the joint must be grooved to allow for multiple weld passes. A thick layer of slag is deposited on the weld, but is easily removed, and may even remove itself after cooling. These electrodes are commonly used for sheet metal fabrication and general repair work. These electrodes are not designed for welding downhill and will trap slag easily. (They work well for learning to weld, but after that move on to real electrodes)

E7018 The E7018 electrodes are designed to be used with AC or DC reverse polarity currents. They have a low hydrogen based flux with iron powder added. The E7018 electrodes have moderate penetration and buildup. The slag layer is heavy and hard but can be removed easily with a chipping hammer. The weld metal is protected from the atmosphere by the slag layer and not by rapidly expanding gases. The E7018 is very susceptible to moisture which may lead to weld porosity.

E7024 The E7024 electrodes are designed to be used with AC or DC, either polarity current. They have a rutile based flux with iron powder added. This welding electrode has a deep penetration and fast fill characteristic. The flux contains about 50% iron powder, which gives the flux its high rate of deposition. In other words, a lot of the flux actually gets deposited as weld metal... The heavy flux coating helps control the arc and can support the electrode so that a drag technique can be used. The drag technique allows this electrode to be used by welders with less skill. The slag layer is heavy and hard but can be easily removed. Because of the large fluid puddle, this electrode is used in the flat and horizontal positions only.

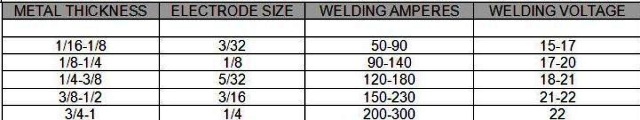

Stick Welding Amperage Guide

On most stick welding machines , the voltage is predetermined. It is included here just in case you have a really old machine

leave stick welding learn about welding certification

see video on different uses for stick welding rods shielded metal arc welding

Shielded metal arc welding rods different types of welding rods

types of welding

Stronghand welding magnet

Custom Search