Tig Welding Is the Most Versatile type of Welding

TIG Welding Carbon, Stainless, and Aluminum...and 4130 chromoly with a 200 amp TIG inverter

"Tig Welding might not be as fast as mig, but it is much more versatile. Just by switching rods, you can go from carbon to stainless to inconel to titanium.

AND just by flicking a switch you can weld aluminum too"

Different Types of Welding like MIG, Stick, Flux Core

TIG welding Filler Rod Basics - What filler rod to use?

ER70S-2 or ER70S6 for Carbon steel and 4130 Chromoly

ER308L for 304L Stainless , ER309 or ER312 for unknown steel non critical applications

depending on the most wanted result.

Do Clear Cups really Help?

Will a Clear 8 cup fit your Torch?

Click here for videos on tig welding steel and 4140

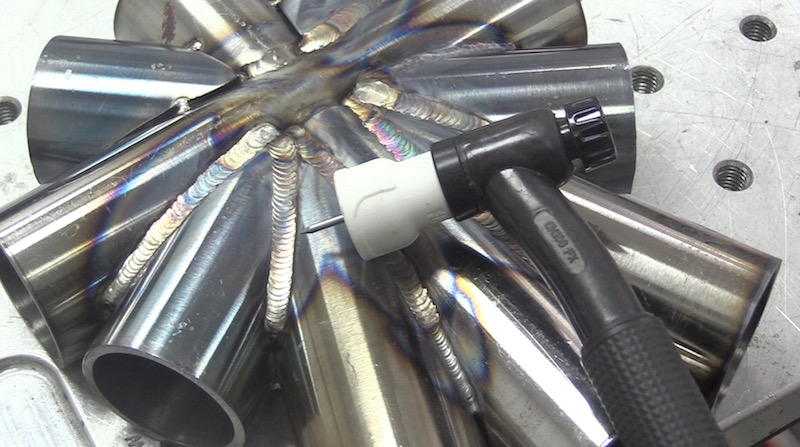

Tig Welding Aluminum

Gas Tungsten Arc Welding (GTAW) is called TIG welding by welders. Old timers still call in Heliarc. Some people insist on trying to call it gas tungsten arc welding (GTAW) saying that the term TIG is incorrect.

Welders will always use the term they are comfortable with, the one they learned first.

Its good to know the proper name because that is what is usually used in engineering documents

Click here for more videos on tig welding aluminum

Tig Welding aluminum requires Alternating current (except in very rare cases...click here to see a video using DCEN and helium to weld aluminum.

Visit the weldmonger store for tig fingers, gas lens kits, dvds

TIG Stainless Steel

click here to learn more about the Furick ceramic 12 cup

TIG Welding Stainless Steel pipe Root pass technique

This short video shows bridge tacks vs penetrated tacks, root pass technique and all settings used

Click here for videos on tig welding stainless steel

One of the best things that will help you tig weld stainless steel is a gas lens. When you need to extend your electrode it can be a game changer.

TIG, welding can sometimes be done without using Filler metal but this only works in certain applications...like food service code welds on kitchen equipment where looking smooth and clean is sometimes more important than weld strength.

Most of the time filler metal is used to allow for a full strength weld.

The techniques used in TIG are similar to those used in Gas welding because both hands are used in manipulating the torch along with the filler rod.

TIG is just better.

TIG pinpoints the heat much better and a foot control is often used to regulate amperage. There are dc and ac/dc power units with built-in high frequency generators designed specifically for TIG. These automatically control gas and water flow when welding begins and ends.

If the torch is water-cooled, a supply of coolant is necessary (It is best to use a coolant recommended by the manufacturer in order to get the best performance and longest life from your torch).

TIG Torches are made so that electrodes and gas nozzles can readily be changed. Automated TIG welding equipment may include devices for checking and adjusting the welding torch level, equipment for work handling, provisions for initiating the arc and controlling gas and water flow, and filler wire feed mechanisms.

Tungsten Electrodes

There are several different tungsten electrodes out there.

2% thoriated, Ceriated, lanthanated, E3, LayZr and more but unless you want to spend a bunch of money trying all of them, just get some 2% lanthanated 3/32" and go from there.

2% Lanthanated Tungsten Electrodes...as good as thoriated without the Radioactive thorium

I stuck with 2% thoriated for a long time. It worked but on A/C the tip kind of got jacked up at high amperage. I tried 2% lanthanated and learned that it works great on DC and even better on A/C. And For TIG inverters like the Miller Dynasty 200dx and numerous others it holds up really well at higher AC frequencies like 120-250 HZ.

The main drawback is that is does not break easily...you have to cut it with a grinder. It is not as brittle as thoriated.

But if there is anything truth to the caution about radioactivity, then it is definitely worth swapping over to 2% lanthanated.

Metals Commonly Welded with TIG:

Carbon and low alloy steels

Stainless steels like 304, 316,321. 17-4, 410

Nickel alloys like Inconel, Hastelloy, Waspalloy etc.

Aluminum alloys like, 3003, 5052, 6061

Magnesium alloys

Titanium

Cobalt alloys like Haynes 188, and L605

Refractory alloys like columbium, molybdenum, tungsten

Copper alloys like aluminum bronze , nibral bronze, pure copper

Items that are commonly welded with the TIG process are:

Carbon steel:

DOM tubing, 1018 sheet metal, Root passes in piping systems, Castings, Tool and die, Injection molds

Stainless steels:

Food service and kitchen equipment, Aerospace components, Surgical and pharmaceutical components, Automotive exhaust and other components, Nuclear piping and components,

Nickel alloys:

Aerospace components,

Surgical and pharmaceutical components,

Heat treat oven components, exhaust collectors

Aluminum:

Truck boxes,

Castings,

Aerospace ducting and other components,

Wheels,

Boats and boat props,

Tanker trucks, tuna towers

Magnesium:

Aerospace gearboxes, some ducting, and other components, Old Volkswagen engine parts, Some Chainsaw housings,

Titanium:

Aerospace Fan blades, ducting, and other components Piping for ocean applications, Golf clubs, Helicopter compressor components, Race car parts,

Cobalt Alloys:

Aerospace hot section engine components,

Hard facing applications for earth moving and mining, Wear resistant surfaces for manufacturing,

Copper alloys:

Nibral bronze marine components and boat propellers, Aluminum bronze valve bodies, Bronze and brass castings, Pure copper

Tig Welding Equipment

When it comes to Tig equipment, Miller tig welding machines are hard to beat. But there are lots of other choices now.

It can be hard to filter out all the sales and marketing talk and get the truth about reliability, performance, and customer service.

Get the best machine you can afford.

But dont think you have to wait to save thousands of dollars to get started.

You can get a pretty good AC/DC TIG welder for way less $1000 right here and even if you add a nice TIG cup kit, you will still be around $1000

people also asked

What is better TIG or MIG welding?

TIG welding is better for certain things like thinner metals and high performance alloys like 4130 chromoly and superalloys like inconel and titanium.

Switching from metal to metal is as easy as grabbing a different filler metal and changing a few settings.

Mig welding is generally must faster than tig but switching metals requires changing out a spool of wire and switching to a different shielding gas.

What is TIG welding used for?

TIG welding is used for nearly all metals like carbon steel, 4130 chromoly, stainless steel, nickel alloys, aluminum, magnesium, and titanium. It is especially good for thin metals.

TIG welding is more versatile than any other welding process because switching from one metal to another only requires using a different filler metal along with changing a few settings.

What is difference between TIG and MIG?

The different between TIG and MIG is like precision vs speed.

TIG welding uses a tungsten electrode to produce the arc and filler metal is fed with the other hand.

MIG welding is a wire fed process where the filler wire is the electrode and also the filler wire.

What does TIG welding mean?

TIG stands for Tungsten Inert Gas and originally, helium was used for the inert shielding gas.

Thats why TIG was once called Heliarc.

Once it was discovered that other gases and gas mixes could be effective that were not technically inert, the name was changed to Gas Tungsten Arc Welding.

But most people still call it TIG.

TIG Tips

TIG welding with a Stick Machine???

You can TIG with almost any DC welding Stick welding machine and you can stick weld with any almost any TIG machine.

Why buy a TIG machine then? Well TIG machines, that is welding machines that are specifically designed for TIG welding, simply do it better. They have features like high frequency start, remote amperage control, and solenoid valves for shielding gas.

TIG welding with a DC stick welding machine involves scratch starting and using a torch with an argon valve built in. But if you just want to be able to make good looking welds on thin metal and you already have a DC stick welder, you will be surprised at what you can make happen with a scratch start TIG rig.

How to hook up a scratch start Tig Torch to a Stick Welder.

Oh! One more useful tip. If you just need to burn a stick rod or 2, why bother changing over to a stinger? This really works!

Cant find what your looking for? Try again

Custom Search

Does Tig welding have to be so slow?

Tig is always slower if you do it by the book. But why not think outside the box and break the rules? On some metals you can weld pretty fast. Especially if you consider there is no cleanup afterwards.

How do you weld clear anodized aluminum?

Most guys that weld tuna towers and marine parts can give you some tips on this. Most of them hook up a switch on the torch and "bump weld" manually by going from on to off again and again slightly overlapping puddles. This seems to break though the anodized coating. Boat owners will not put up with ugly welds or welds with a bunch of sanding or wire brush marks.

Which rod is the best one for the job?

That’s a really broad question. But here is some good basic information:

Carbon steel? But you are not sure exactly which grade? , use e70s2, 3, 4 or 6..er70s2 is the most common and easiest to get at your local welding supply.

Stainless? But not sure which grade? use er308L

Aluminum but not sure what alloy? use 4043 (or 4943 which is a fairly new rod)

Steel to copper? Silicon bronze

Cast iron? Nickel rod or (aluminum bronze using AC)

Carbon steel to stainless steel? ER 309

If the weld is critical, you need to find out exactly what you are welding and use substantiated engineering recommendations for welding rod used.

How can I tell what type metal I am working on?

There are a few good ways to get an idea of what metal type you are dealing with.

First off use a magnet.

If the metal is magnetic it is either carbon steel, cast iron, cast steel, a magnetic grade of stainless steel or severely cold worked stainless steel, or pure nickel.

Not magnetic? Could be practically anything else.

Aluminum, titanium magnesium, copper, cobalt, nickel alloy?

Spark test is another way to narrow it down, but it takes a lot of practice. carbon steels make lots of sparks and the pattern of sparks is different depending on how much carbon content.

300 series stainless sparks a lot less and the sparks are more red.

Titanium sparks like a mother whiz monkey. Bright yellow almost white sparks that stream like several feet.

how to tack weld stainless steel sheet metal

tungsten electrode types