7018 Uphill Outside Corner joint

weldmonger store products

This page is about trying to dial in the settings for a 7018 uphill outside corner joint.

And when I say "trying to dial in" what I mean is deciding whether to use one or 2 passes, what amperage works best, what machine to use, how to fit the joint, etc.

So I brought you along for the ride.

Amperage setting for 7018 uphill

When you are welding uphill using a 3/32" 7018 on a 1/4" thick outside corner joint, you dont need as much amperage as you would for an uphill TEE joint.

for a Tee, I would use around 90-95 amps.

but for the outside corner, 75 amps was about right.

Now I think 75 amps sounds pretty cold. sincke I usually run a 7018 3/32" rod at 90-95 amps in flat and horizontal.

But since this joint is uphill, it just does not need as much amperage.

Anything more than that just got out of control and chewed the edges up pretty bad...I did use 80 amps for a few tries on single pass welds, and while it ran ok, it really chewed up those corners no matter how long I held the toes.

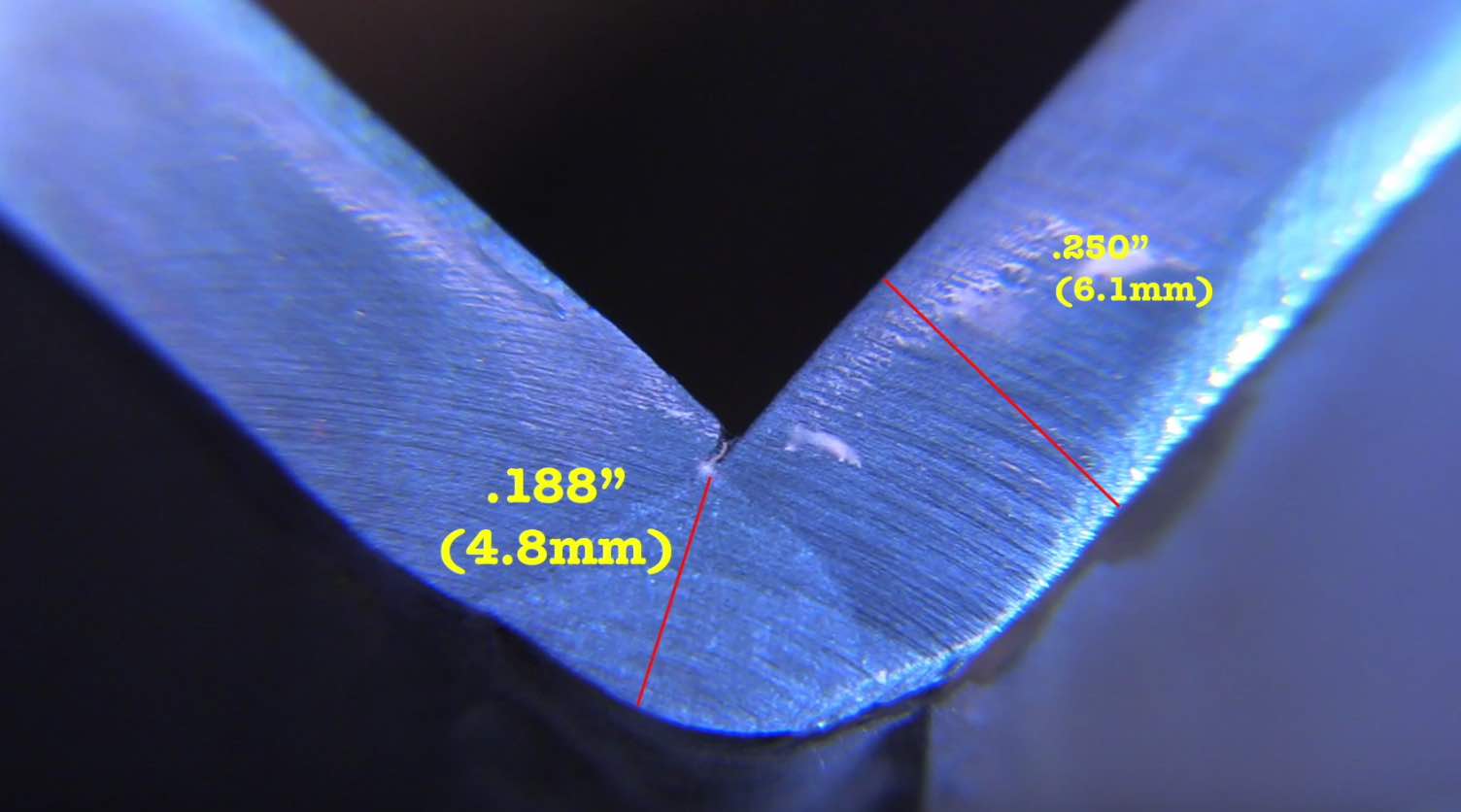

I wound up using 2 passes for the best results.

Cut and etch tests showed the results

Cut and Etch results

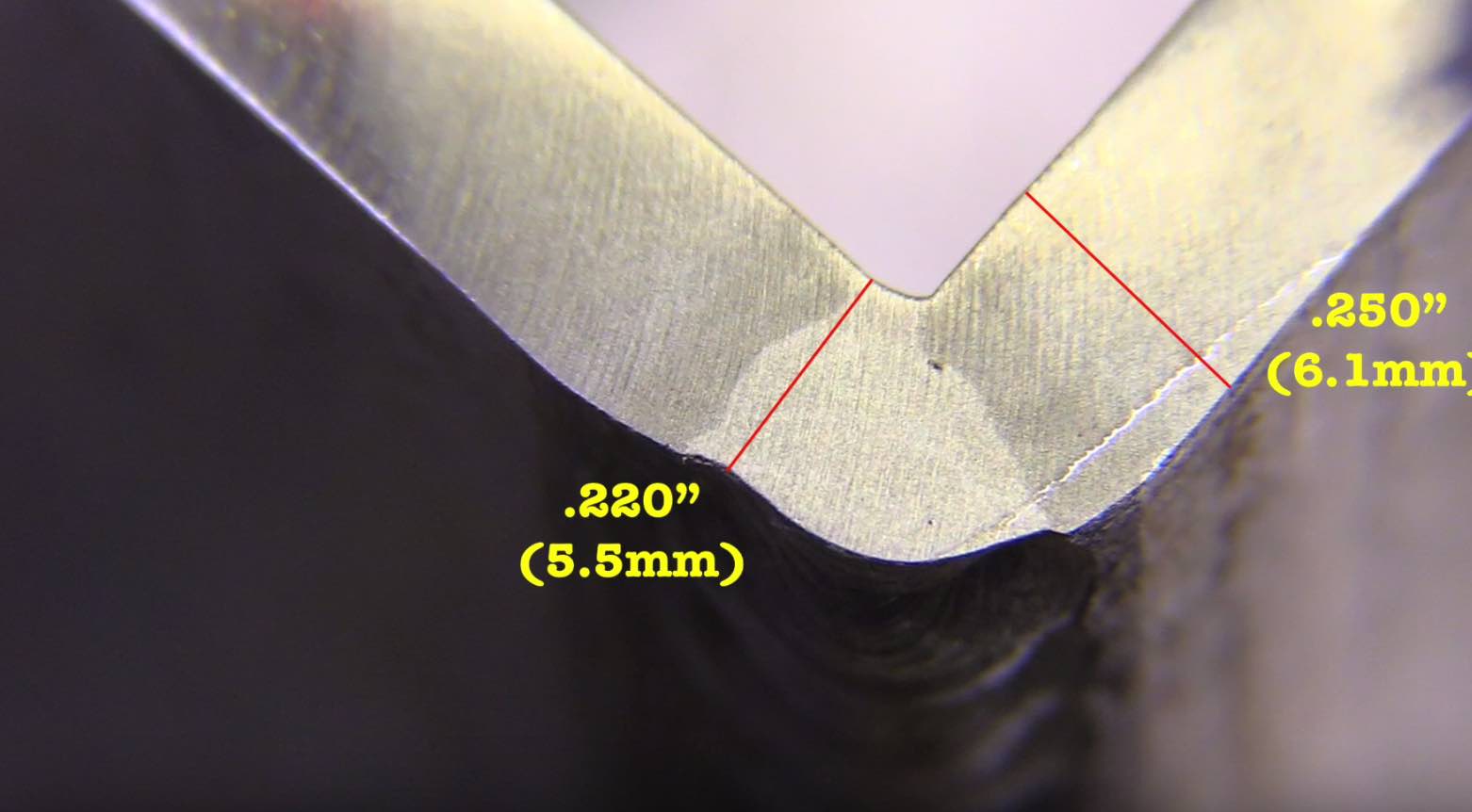

single pass with slight gap

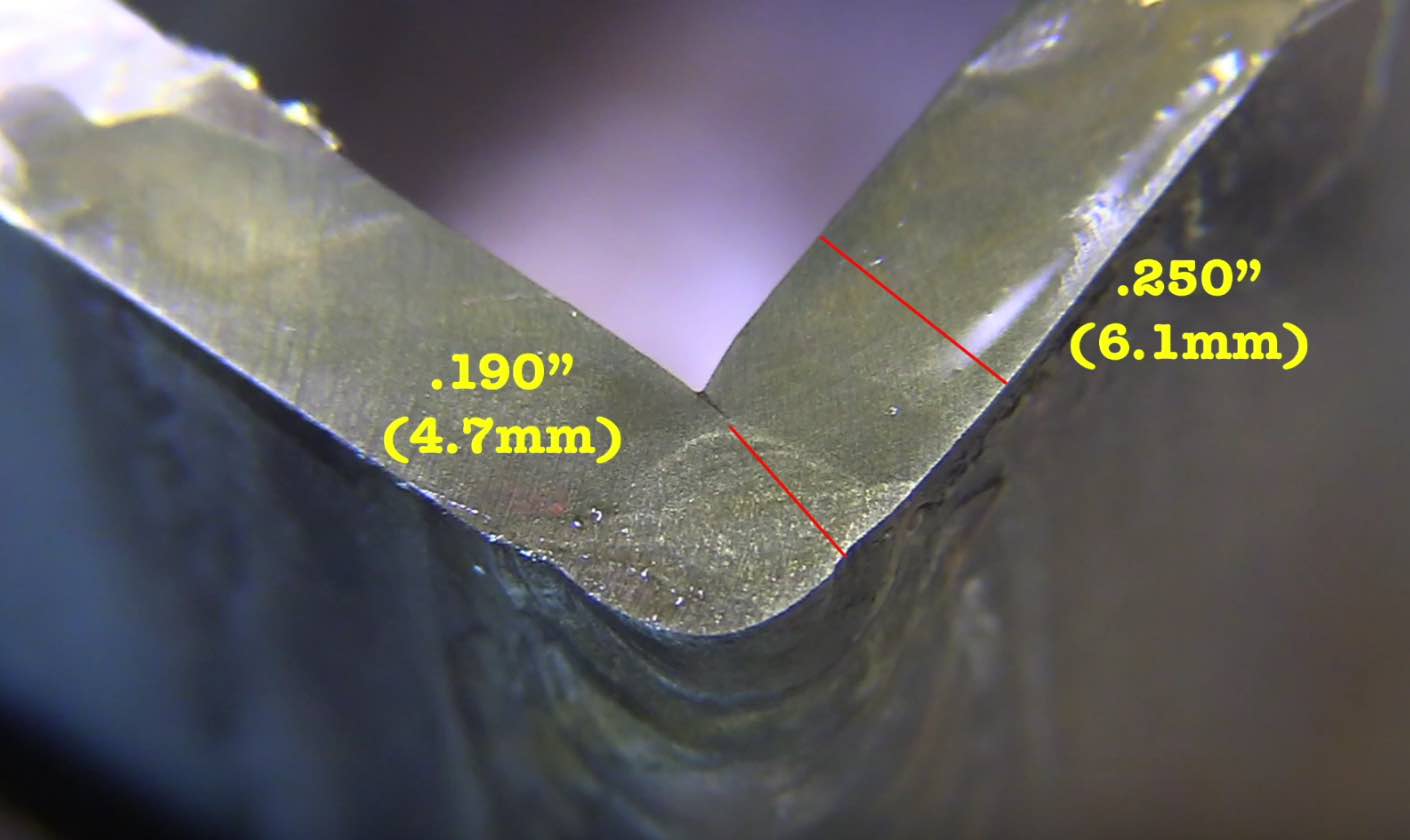

2 passes with overlap

2 passes

The reason I like to do Cut and Etch testing on welds is that is the only way to really prove out a technique or procedure. The cut and etch test really correlates what you think you see to what actually happened.

I saw really quickly just how much affect the fitup has on an outside corner weld.

I fit the joints up corner to corner and with a slight gap..but as I progressed along the joint, as often happens, the weld metal shrinkage pulled the 2 pieces together and actually caused a bit of overlap.

when there is any overlap on an outside corner joint, it really changes the overall cross sectional thickness of the weld.

Engineers know that a fillet weld is not a full strength weld and typically dont utilize fillet welds where a full strength weld is required.

Even so, its important to consider just how much difference a fit up makes in an outside corner.

Any overlap reduces the cross sectional thickness of the weld a lot.

That is why you will often see a weld symbol that also requires welding a fillet weld on the opposite side of an outside corner joint....to provide adequate strength.

So a fitup corner to corner with no overlap, along with a 2 pass weld at 75 amps worked best for me.

I hope this helps..

see more videos on stick welding with 7018 by clicking on the links below

stick welding uphill on a tee with 7018