Dual Shield Flux Core vs 7018 Stick Welding

Both Dual Shield Flux Core and Stick Welding (smaw) are good and proven welding processes.

Each process has its pros and cons.

Stick welding with 7018 1/8" electrodes is very commonly used for structural welding of all kinds and is super versatile because very simple equipment is required and because welding outdoors in windy conditions is not a problem.

All you really need is a generator welder capable of producing around 150 amps and enough welding leads to reach the weld.

But for welding in a shop environment, and even for a lot of field situations, dual shield flux core sure can be a lot faster.

I met my friend JD Brewer at Fabtech 2015 in Chicago and since then have watched him fabricate and weld many different types of mezzanines, work platforms, hopper platforms, tanks, and pipe welds.

JD uses Dual shield flux core whenever possible.

Partly because he is really good at it.

but mostly because JD is in business to make a profit and dual shield flux core helps him get jobs done quicker.

this video shows how much faster Dual shield flux core can be than using a 7018 1/8" rod for vertical welding.

why dual shield flux core is faster than stick

Dual shield is faster than stick welding for 3 main reasons...

- the range of wire speed feed and voltage that works is huge.

- no stopping to change rods

- higher metal deposition

There might be a few more reasons but lets take a look at these 3 reasons...

Range of settings...

for the first vertical weld in this video settings were 24 volts and 270 inches per minute using .045" easb 7100 dual shield flux core wire.

Those are good all around settings JD would use for a job where all position welding was needed on 3/16" to 3/8" thick so he would not need to ever adjust settings for flat, horizontal, vertical or overhead.

Time to weld 14 inches was 2 minutes so travel speed was around 7 inches per minute

I welded the same joint using 7018 1/8" rods at 115 amps and it took over 5 minutes because I had to stop and restart and because travel speed was much slower at around 3.5 inches per minute.

I also had to adjust amperage near the end of the weld and move the ground clamp because arc blow go so bad with the 7018...a problem JD didnt encounter at all using dual shield.

And since the 24 volt and 270 ipm setting was a fairly low setting as compared to the upper limit settings for .045" wire, JD set the Esab Rebel 285 to 25.2 and 500 ipm and ran a vertical uphill run.

14 inches only took 1:04 ...thats almost 14 inches a minute on vertical uphill.

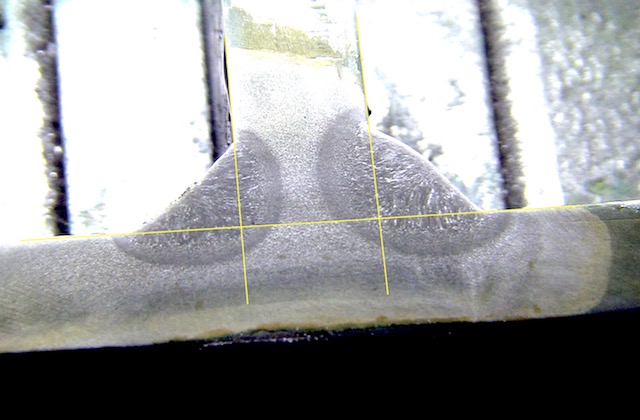

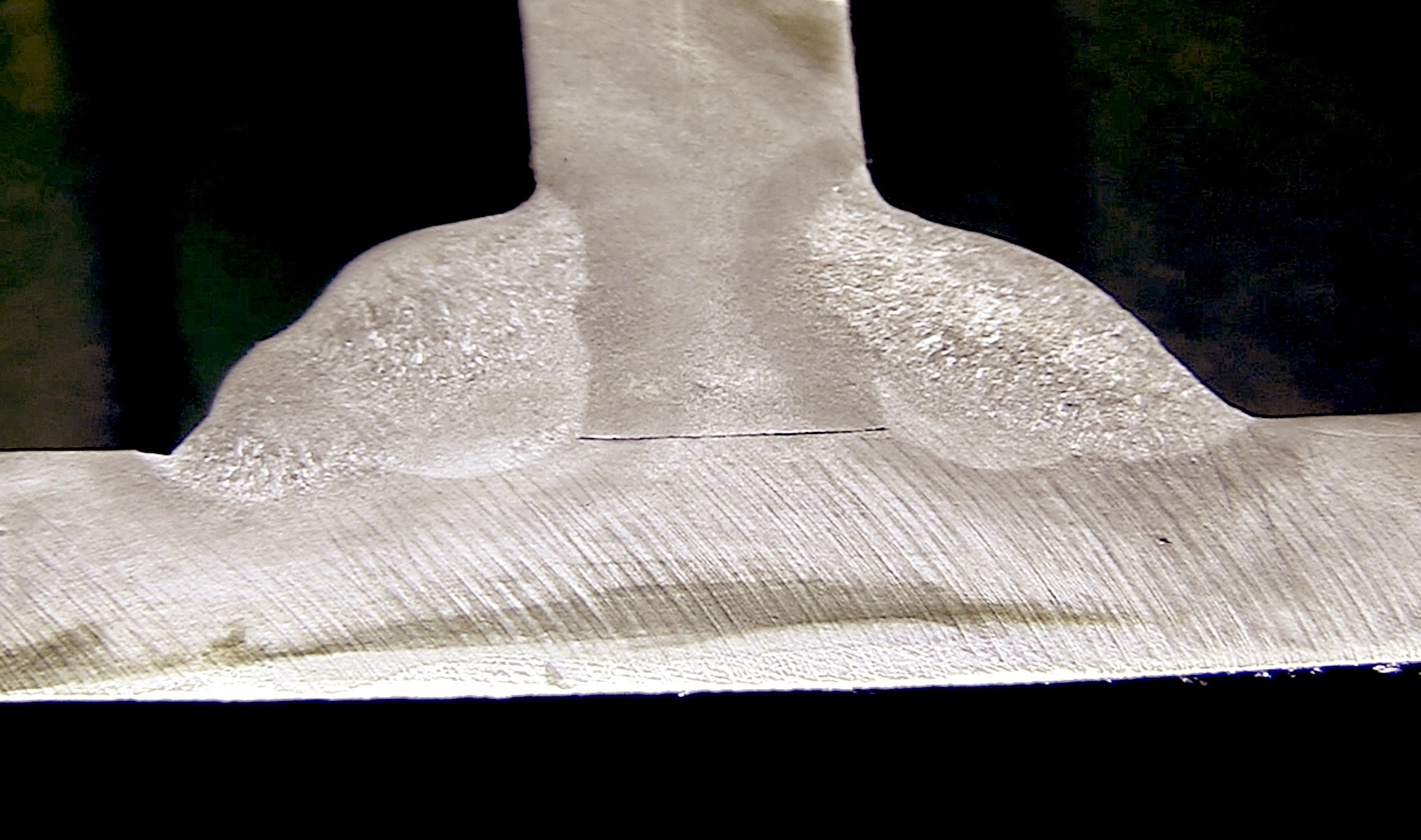

So we decided to do a quick cut and etch test to see if it penetrated ok.

The weld on the left was with 25.2 volts and 500 inches per minute wire speed. Both welds look good to me, but due to the increased travel sped, the weld on the left penetrated slightly less.

7018 3f cut and etch cross section

the weld on the left was done using stringer beads...

a root pass bead with 2 stringers stacked on top.

The weld on the right is the one shown in the video.

A root pass followed by a weave pass.