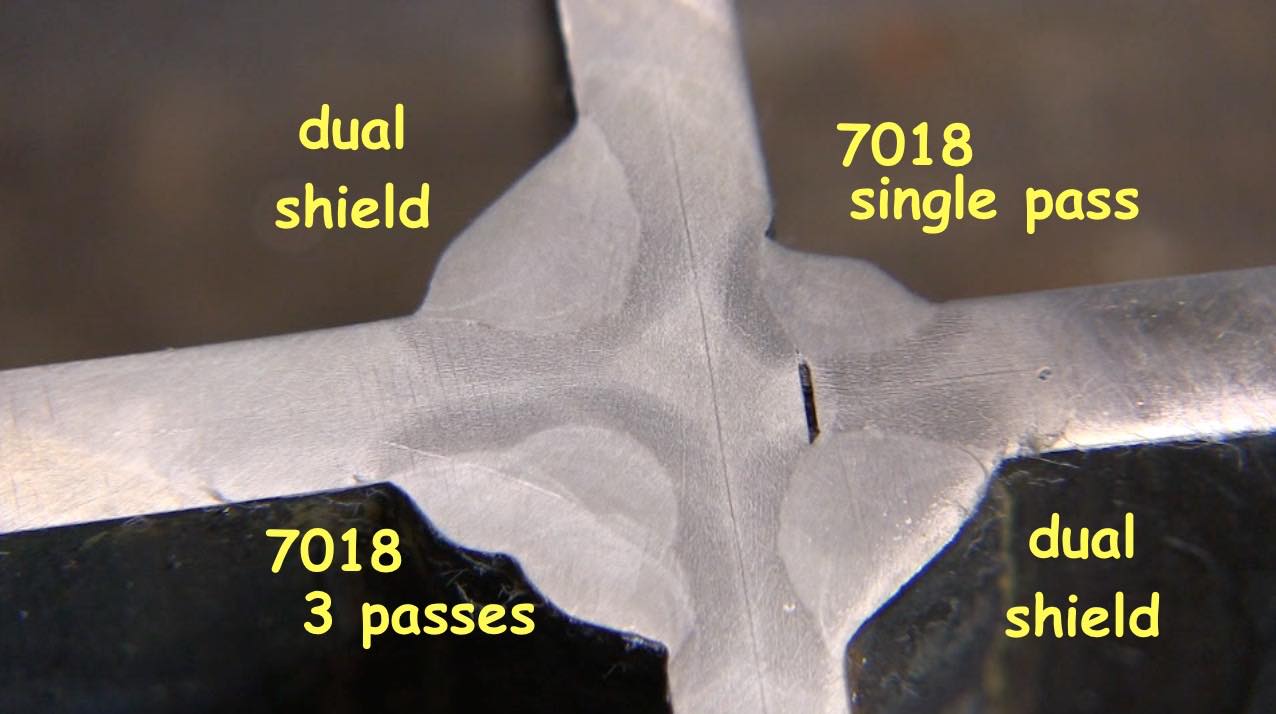

Overhead Welding with 7018 and dual shield flux core

If you are struggling with overhead welding using 7018 stick electrodes then here is a piece of advice for you.

Set the machine hot enough that when you hold a tight arc the rod will not stick...

Then hold a tight arc.

Sure, its not quite that simple but that is the main thing folks get wrong.

I remember when I was learning to weld overhead, I thought that I needed to lower the amperage to prevent the weld puddle from sagging.

Boy was I wrong?

The amperage for overhead welding is about the same as for welding on the bench in flat or horizontal position.

The key is a tight arc and good rod angle.

keep a tight arc and dont get crazy with the electrode angle and things will go alright.

Amperage for Overhead Welding with 7018 1/8" (3.2mm)

A rule of thumb for setting amperage for 7018 rods is one amp per one thousandths of diameter.

since 1/8" = 125 thousandths, 125 amps is a good starting point for 1/8" 7018 rods.

Its a good starting point but often times increasing amperage to around 135 amps works good too.

It really depends on the manufacturer and thickness and composition of the flux coating on the rod

Overhead Welding with Dual Shield flux core

First things first...

make sure the polarity is set correctly.

I spent an hour chasing my tail while filming this video because I accidentally set the polarity wrong.

Dual shield flux core wires typically require DCEP

Self shielded flux core wires typically require DCEN.

For this video I used 1/4" thick steel and .045" (1.1mm) E71t-1 wire.

24 volts, 333 ipm, 30cfh flow rate using C25 gas.

Overhead 4g plate test with backing

I worked with my friend Andrew Cardin to film this 4g welding test video.

and right below is a vertical 3g test video using dual shield flux core

Final thoughts for welding overhead

Welding Overhead is slightly more difficult than flat or horizontal mainly because...

Its awkward....its harder to maintain a good line of sight

Gravity not only affects the molten puddle but tends to pull your arms down which makes it harder to hold a tight arc or short stickout.

Its harder to get comfortable so that you can be steady.

Once you figure out how to work around these issues, its just not that hard.

Remember, just do the same thing you would do on the bench and hold a tight arc.