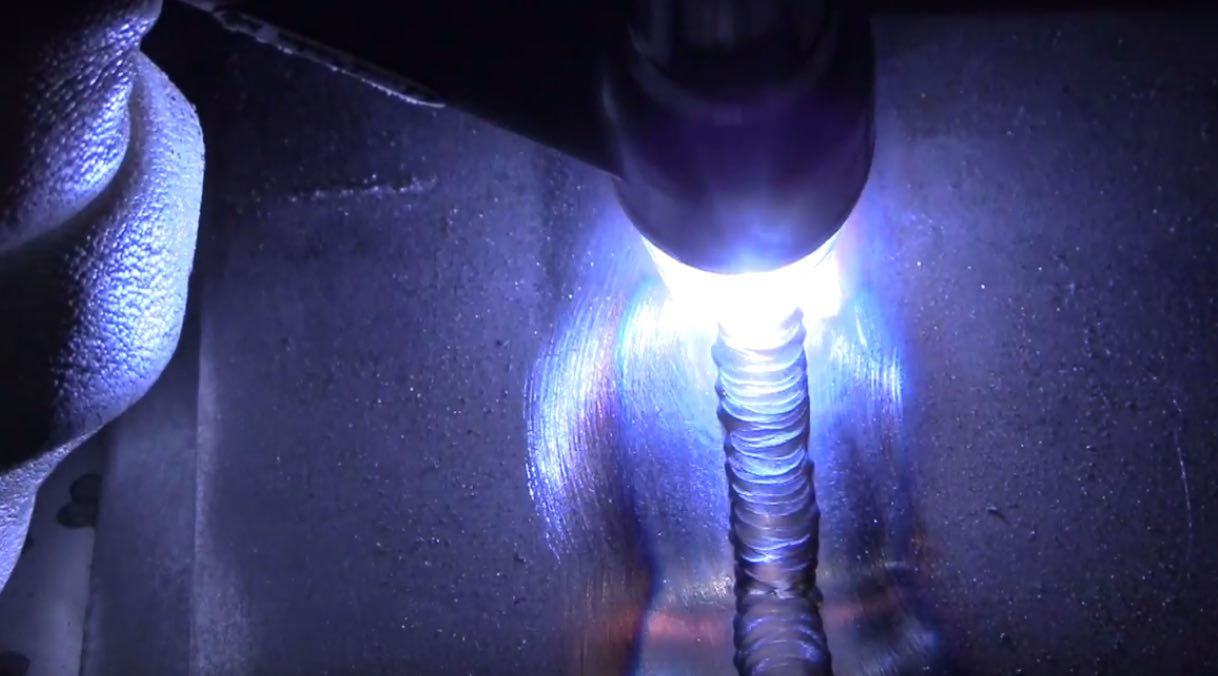

TIG Weld Root in 11ga Butt Joint

click here or on image below to learn more about the clear furick #8 cup

This video shows techniques, arc shots, and tips for how to tig weld an open butt root in 11ga steel.

The weld in the video was done in the flat (1G) position but these same techniques will work in all positions with minor adjustments.

Back when I taught welding for a large company, we used the Hobart training DVDs and workbooks for basic tig training.

One of the exercises in the book was this same 11ga joint except that there was no bevel on the plates and it was supposed to be done with little or no gap.

On an 11ga cold rolled steel small test piece, by the time you get penetration using no bevel and no gap, the piece really gets saturated with heat and while it can be done, its not a very realistic joint.

In fact, in my 40 plus year career, I have never needed to get full penetration on an 11ga butt joint with no bevel or gap.

And that brings me to this question...

Why even practice this joint?

Why not practice with a bevel and a gap?

Because practicing with a bevel and a gap provides excellent practice for something commonly encountered in the welding industry.

and that is schedule 10 pipe with a wall thickness similar to 11ga steel.

which is around .120" (3mm)

Joint details for this TIG Weld

11ga Cold Rolled aisi 1010-1018 steel

30 degree bevel

3/32" (2.4mm) gap

.030" (.75mm) land

Root pass lay wire using 3/32" wire 90-100 amps

Second pass using 1/8" wire 100 amps

2% lanthanated electrode 3/32"

#8 clear furick Cup and 20 cfh argon

Cut and Etch

There is always a chance of lack of fusion when making a multi pass weld.

So I like to test welds often to verify what I thought I saw vs actual results revealed by the cross section.

I used a zip wheel on a grinder followed by a 80 grit flap disc, followed by a 2 scotch brite pads to get the surface smooth enough to etch without any deep scratches that might conceal defects.

I etched using a passivation solution made for stainless steels.

summary

in order to get good results with tig welding, the metal needs to be clean enough.

Even though I used cold rolled steel for this video ( which is normally pretty darn clean) I still cleaned the metal in the weld area with a flap disc and an acetone wipe....it is also a good practice to wipe the filler rod with acetone.

I also cleaned between passes using a flap disc and wire wheel to make sure I was not welding over grey oxidized metal.