TIG Welding a Titanium Bike Frame

Basic Titanium tig welding mistakes

- HOME

- Welding Titanium

- Titanium Bike

Titanium bike welding with Mike Zanconato.

I visited Mike Zanconato of Zanconato Custom Cycles to learn and film some of his process for tig welding titanium bikes.

Titanium

has become a very popular metal for bike builders due to its high

strength to weight ratio and corrosion resistance.

So not only is a

titanium bike super light weight, but it does not require painting,

powder coating, or other surface treatment to prevent corrosion...and that is a big benefit.

But Titanium properties can be lost during the welding process if things are not done right.

Titanium is not all that difficult to weld...but strict cleaning and gas shielding are mandatory for high quality welds.

So

Mike started by coping some titanium tubes on the Bridgeport mill using

a tube coping fixture made by anvil bikes. ( the hole saw that mike has

found best for coping tubes is Starrett fast cut bi metal).

After

tubes are coped, Mike deburrs with a file and belt sander and cleans

the tube both inside and out using acetone. For the inside, Mike uses an

acetone soaked shop towel and a ram rod that resembles something you

would clean a gun a barrel with.

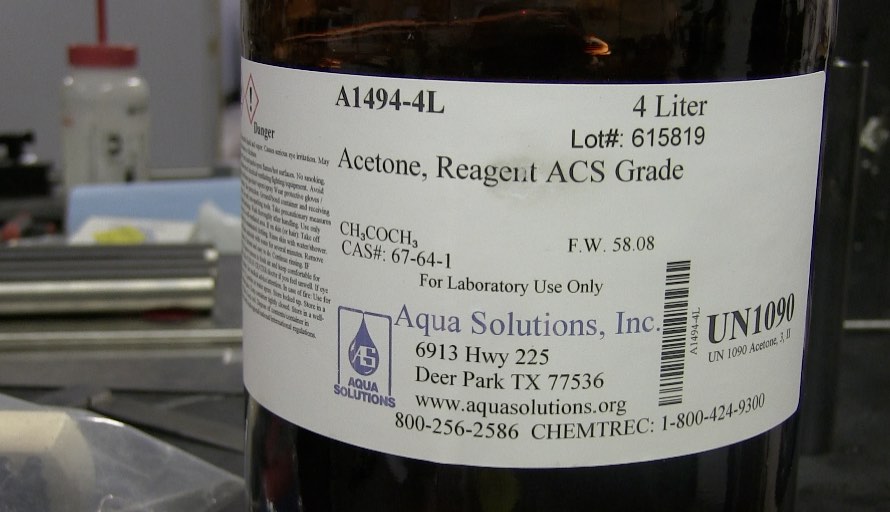

But Mike does not use just any old acetone. Mike has found that using reagent grade acetone can really make a difference in the overall appearance of a completed titanium weld.

Because even small residues of impurities on titanium can cause discoloration under the heat of welding.

We had a long discussion on this topic and Mike learned about potential issues with using plain industrial grade acetone by listening to a lecture given at MIT by a metallurgist. ( I listen to these metallurgy lectures on youtube all the time …especially the ones given by Dr Seagers)

This MIT metallurgist recounted a situation where an aerospace company was having cracking issues with titanium. And the cracking problem was isolated to impurities like hydrocarbons in the industrial grade acetone.

After switching over to using only reagent grade acetone, the cracking issue disappeared.

Now I am not trying to claim that every titanium weld will crack after using plain industrial grade acetone.

Far from it. Because I have used it on hundreds of titanium welds myself without cracking issues.

But it is worth noting that under certain circumstances, using the reagent grade got rid of a cracking issue on a certain type titanium alloy part.

Probably due to an absence of hydrocarbons left on the surface.

So after cleaning the tubes inside and out to get rid of any oil residue, the tubes are placed in the welding fixture.

This fixture is also from anvil bikes and is equipped with argon purge fittings that allow purging the entire frame. (This usually requires greater holes to be drilled in the frame tubes to allow argon to flow freely throughout the frame..these breather holes also prevent pressure from building up as the frame is sealed up from welding.

Several small tack welds are made on each joint after the Frame is completely purged out with argon.

Once the tack welds are done, and some other short welds are made, the Frame is removed from the fitup fixture and retaped and purged again so that the frame can be easily accessed for welding on the other end of the fixture where there is a multi angle arm clamp that allows the frame to be easily turned every which way for access to every joint.

In the bicycle builders community , it is common practice to make 2 passes on each titanium weld.

It seems no one really knows why other than its easier to get complete fusion into the root of each joint by using 2 passes.

The first pass is often a fusion pass with no filler. But since the wall thickness of titanium bike tubes is only around .035” or less, its wise to keep a piece of filler wire in your hand while fusing the first pass in case the edge of a tube tries to keyhole.

Titanium filler rods are sticky like bubble gum at welding temperatures.

This really becomes obvious on fillet welds like tee joints where there are 2 surfaces for the rod to stick.

to add to the problem is the fact that titanium becomes magnetic at temperatures near melting.

So the 2 sides of a tee type joint will pull the hot tip of the rod and make it stick to the edge of the weld.

Sometimes you just have to stop ,,,,let off the foot pedal, let cool and break the rod loose.

But to avoid sticking the rod, aiming for the hot center of the puddle, or gently allowing the arc to melt off drops of rod help in prevent the filler rod from sticking.

Mike and I experimented using pulse settings for the first fusion pass and found that 50 pulses per second , 30% pulse time, and 30% background worked pretty well.

I like to use my rule of 33 for situations like this…

33 pulses per second

33% pulse time

33% background

Its a good starting point for coped tube joints. And seems to really help with filling in gaps.

The second pass seemed to weld better using straight current with no pulse at around 45-55 amps

Using a Furick BBW cup for TIG welding titanium bike welds...click here to learn more about the BBW cup

Just any old cup won’t do for tig welding titanium

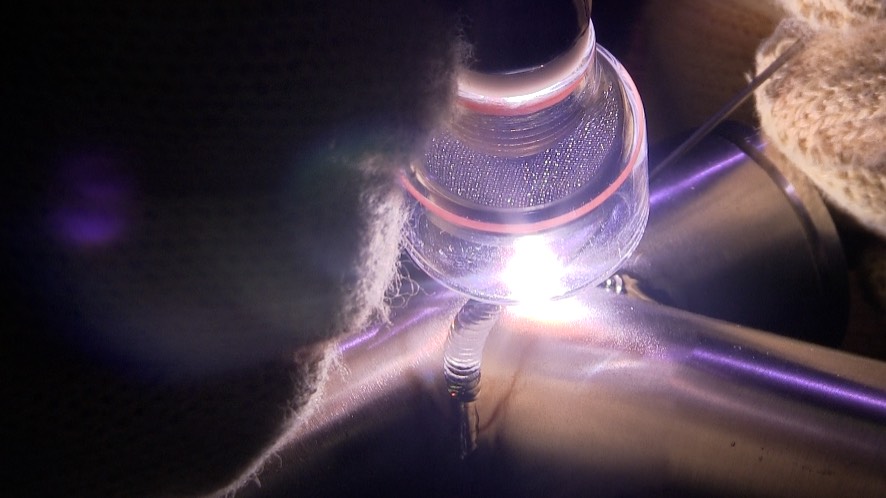

Mike used a Furick BBW cup for this video which is a #16 size clear cup.

The clear BBW really helped with the filming but pyrex type cups can break if you drop them.

I

really like the ceramic version of the BBW cup because it offers equal

argon shielding, but is much more durable than the clear version.

I have both versions available on my store at weldmonger.com

Bike

customers….folks that order a titanium bike from Zanconato custom

cycles , want to know that their bike frame will hold up to years of use

and abuse.

They expect the Bike to not only look great, but also to

perform great for years and years and that is why Mike takes the utmost

care in making sure he implements all the best practices for tig welding

titanium.

Cleanliness, purging the back side of the weld, and

making sure all welds blend in nicely to the tubes ensure that Mikes

welds will hold up for as long as possible.