Welding metallurgy of Nickel alloys..Day 3 of Down and Dirty Metallurgy

Down and Dirty Welding Metallurgy for Nickel alloys

Hastelloy X, Inconel 625, Inconel 718, Waspalloy, Rene 41, Nichrome V, Inconel 713c. These are just a few of the hundreds of nickel alloys.

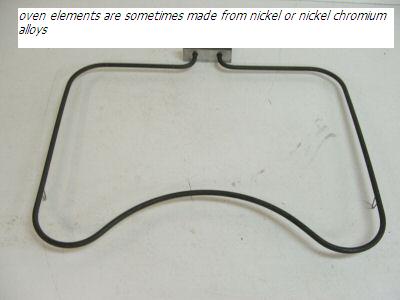

What kind of stuff is made of Nickel alloys? Aircraft Engine parts like: turbine blades, turbine blades, burner cans, engine brackets, engine cases. Process piping for paper mills and nuclear plants is sometimes made from nickel alloys. Heating elements for industrial ovens are also often made from nickel alloys. There is a good chance the some of the elements in your household toaster or oven are made from nickel.

Before we go any further on the welding metallurgy of nickel alloys, remember on day one when I talked about how metals harden? And that carbon and low alloy steels, cast iron, and some 400 series stainless steels harden by heating and then quick cooling? And that practically every other metal actually got softer by heating and then quick cooling? And that you needed to understand that before going any further? Well it is day 3 of the welding metallurgy course now and we are talking about nickel alloys. Are you getting it? If you are, then you already could guess the answer to this question: If I heat a nickel alloy red hot and then drop it in a bucket of ice water, will it harden? Well, what’s the answer? Have you been paying attention? The answer is …….NOPE This is why nickel rods are used to weld cast iron. Because even when mixed with carbon and other elements that make steel hard, nickel alloys will not get hard from heating and quick cooling. We know that some nickel alloys are hardenable by heat treatment so how is it that they are heat treatable and yet they will not harden by heating and quenching? Well here it is… are you ready? Because this is another one of those down and dirty principles that if you really grasp, you will be miles ahead of most engineers. The heat treatable nickel alloys harden by aging. In other words, by heating to an elevated temperature for an extended period of time (sometimes over 18 hours). Holding these nickel alloys at a precise elevated temperature alloys the metal to strengthen by certain elements precipitating into the microstructure. That’s why they call them precipitation hardenable nickel alloys. Want to know more about precipitation? Me neither…. That’s why we are calling this down and dirty welding metallurgy.

Nickel alloys are used in several different industries like chemical refineries, nuclear plants, and paper mills but one industry where there use is prolific is the aerospace industry. That is because some of the nickel alloys will withstand extremely high temperatures and are resistant to corrosion and oxidation at high temperatures. Some of them are complex alloys with small additions of elements like aluminum and titanium, and columbium/niobium that allow for a strengthening response from a heat treatment. With all that long hair talk behind us lets get down and dirty: If you can weld stainless steel, you can weld the nickel alloys. There are just some minor differences. Let’s talk for a minute about thermal conductivity. It might sound complicated but its really pretty simple. Metals conduct heat. That’s why the frying pan handle makes you cuss if you grab it without a pot holder. The heat is not being applied to the handle, but the heat eventually conducts to the handle. Some metals conduct better than others. Copper conducts better than most anything and nickel conducts poorly. The reason stainless steel requires less heat than carbon steel to weld is because of its low thermal conductivity. Even though stainless steels contain mostly iron (over 70%) they contain enough chromium and nickel to lower the conductivity considerably. It’s the chromium and nickel that do it. That said, the nickel alloys contain mostly nickel. Most of them contain upwards of 50% nickel. And so the thermal conductivity is pretty low and heat builds up or is unable to dissipate quickly. Nickel alloys require less amperage and less heat to weld than stainless steels. So one of the main considerations is controlling heat input. Let’s take tig welding nickel alloys for example, if you fart around too long in one place, you can build up enough heat that makes it impossible to outrun. That means when you light up, you need to be able to get moving to avoid heat buildup. (thats not welding metallurgy, just common sense) It’s also really important to keep the puddle shielded really well with argon. What does that have to do with heat build up you ask? Well if the puddle is not shielded well , or if the hot tip of the filler rod is taken in and out of the shielding gas, the puddle will become oxidized and sluggish. A sluggish puddle takes more amperage to wet and move. More amperage will cause heat to build up and the weld with overheat and problems will abound. That is why an oversized tig nozzle as would be used when welding titanium actually helps when welding nickel alloys. Some procedures even call for welding nickel alloys like inconel 718 castings, in very short runs with a long cooling cycle in between welds. Welding metallurgy comes into play here, but you dont want to hear about strain age hardening and formation of laves phases and eutectic grain boudaries. Do You? I didnt think so..otherwise you would be reading PHD type welding metallurgy instead of Down and Dirty...

Bottom line is this: clean the metal, wipe with acetone, use a large tig nozzle, use minimal heat to move the puddle, control the heat by short runs followed by cooling.

Peace Out. Tired of Welding Metallurgy? click here to go to the home page