Miller Multimatic 220 AC/DC pulse tig

click here to visit my online store

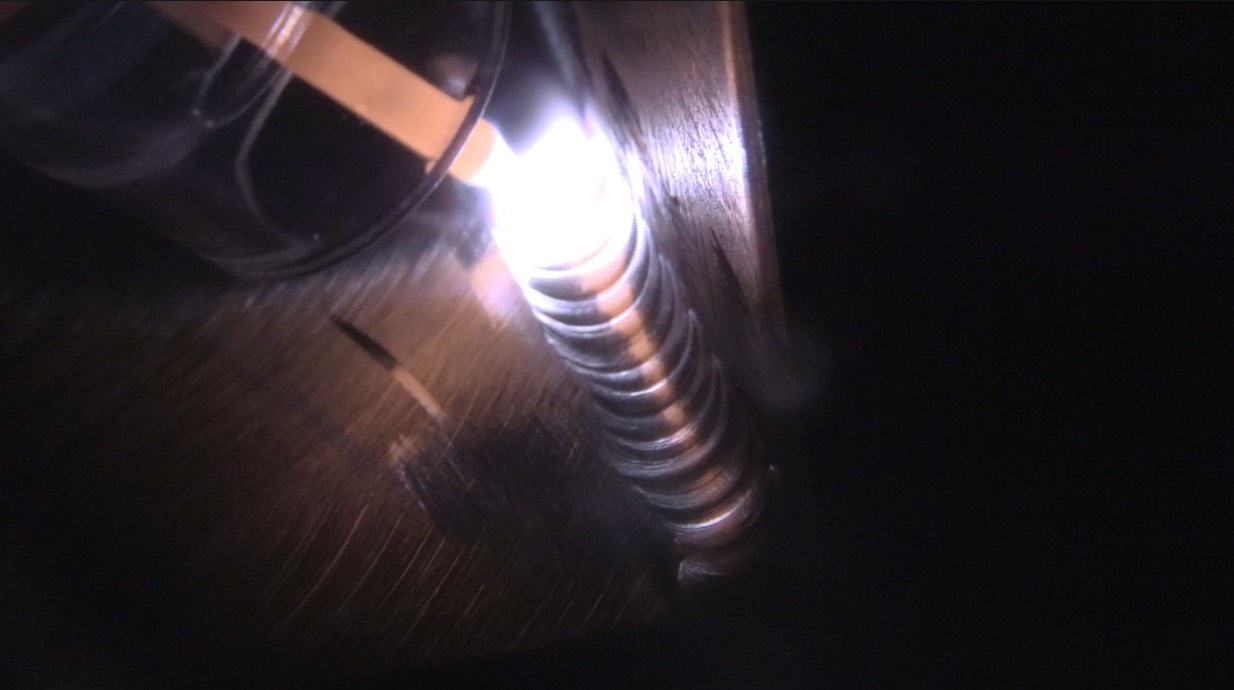

Do you use pulse for TIG Welding?

I dont use it a whole lot, but there are times when it is a really handy feature.

Like when you want to limit penetration.

In this video, I tried to demonstrate how pulse settings can help for tig welding plain carbon steel square tubing where penetrating all the way thru is not needed or wanted.

When you penetrate the back side of something that is not cleaned on the back side, you pull in oxides into the weld puddle and all of a sudden, a nice clean puddle gets all squirrelly and wanders around.

By turning the pulse feature on, and using a bigger rod, I was able to limit penetration and the puddle cleaned right up.

see more tig welding videos

see how the multimatic 220 AC DC did on Mig Welding

The rest of this page is my initial review of the TIG function on a Miller multimatic 220 AC/DC welder

Multiprocess machines that can do lift arc DC tig, mig, and stick are not a new thing.

Those machines are very useful but they are missing one thing.

The ability to tig weld aluminum on AC.

AC TIG has been the missing piece. The one thing that requires you to buy another welder in order to be able to tig weld aluminum

All that has changed now. This is one of a few welding machines available now that can handle all the welding needs for a whole lot of shops.

The Miller Multimatic 220 multiprocess welder does high frequency start tig welding on both AC and DC …

As well as being a mig, stick, or flux core welder.

Esab and Everlast also have multiprocess AC/DC TIG machines now. I have not tried either one yet but I will try oun the Esab Rebel 205 pretty soon so stay tuned for that...

If you want to make sure not to miss that video just sign up for my video newsletter email list below...I will never spam you

Yes, the Miller Multimatic 220 AC DC does tig weld aluminum

The ability to do all processes and all metals makes an AC/DC multiprocess welder extremely useful.

Thats probably why I have received so many questions about this machine.

So I asked Miller if they were interested in sending me one to review.

They agreed for me to do an honest review and say what I wanted.

This is my initial review where I will test out the main TIG features.

( since I wrote this, I also tried out the mig function...click here to see the multimatic mig video page)

All of the previous multiprocess welders I have owned were limited to lift arc tig, mig, flux core and stick welding.

And they have all done just OK.

not spectacular...but OK

It is common for mutlprocess welders to do one process better than the others and just OK on some.

So for this video, I am really more curious on how the tig function works.

The main things I want to know about any tig welder is are the starts crisp and at what amperage does the tig arc start.

The amperage range for TIG on this welder is listed as 20-210 amps.

If the low end amp start is 20 amps, that might nip the edge of really thin sheet metal.

So in order to demonstrate that, I welded on some .024” thick box cutter blades.

and it WAS a challenge to strike an arc on the edge of a box cutter blade without nipping or melting away the edge.

Its got a pretty snappy start, but I discovered that selecting the electrode size to 1/16" even though I was using a 3/32" electrode, lowers the start amperage a bit and really helped.

And what about the high amperage range on DC tig?

So I did a tee joint using 1/4” steel with the welder set at 190 amps using the foot pedal

In order to test the low end aluminum arc, I also lit up on the edge of a .063” piece of aluminum.

What about the aluminum arc at higher amperage?

So I welded a lap joint using 1/4” thick aluminum at 210 amps.

Miller lists ranges of TIG from 24 ga to 1/4” thickness for both steel and aluminum so this was a pretty fair test

- .024” box cutter blades

- Edge weld on 16 ga aluminum

- Fillet weld Tee joint on 1/4” steel

- 1/4” lap joint on aluminum

The main question I wanted to answer for myself was "could I have built my side hustle if I had starteed out using this welder?"

And the answer is Yes...

But that said, there were a couple of jobs I took on over the years where the snappy start on DC would have been a problem.