Tig Inverter Settings part 3...2t and 4t settings with uplsope downslope

Part 1 Tig inverter Settings

Part 2 Tig inverter settings

part 4 tig inverter pulse settings

When you are welding with a tig inverter, there are lots of choices...

Sometimes you need all the amperage control you can get…

but sometimes dragging a foot pedal all over the place is a pain and a torch switch is handy for that

Even though I mostly prefer to have a foot pedal amperage control, There are times when only a a switch on the torch is really handy….like when tack welding airplane fuselages, or welding an aluminum tubing tuna tower.

When you don’t have a remote amperage control plugged in to your tig inverter, a torch mounted switch along with upslope and downslope controls can really help you get things done.

Remember , none of this applies when you have the pedal plugged in. and make sure to select the 2t when a pedal is used.

Not every single tig inverter made has the same controls but most of them have some things in common. Usually a tig inverter will have a 2t or 4t selection and some are labeled 2 t or “2 trigger hold”.

Whatever they are called, they all work kind of the same and understanding one brand names settings will usually help a lot in understanding the next one.

I happen to be using an Primeweld TIG 225x for this series of demonstrations. I have been using tig welding inverter welders for a very long time and they are all layed out a bit differently.

On the primeweld tig welder that I used for these demonstrations, there is a rocker switch that is labeled 2t and 4t.

Its usually labeled a bit differently on a Miller or Lincoln but on the primeweld, here’s how it works…

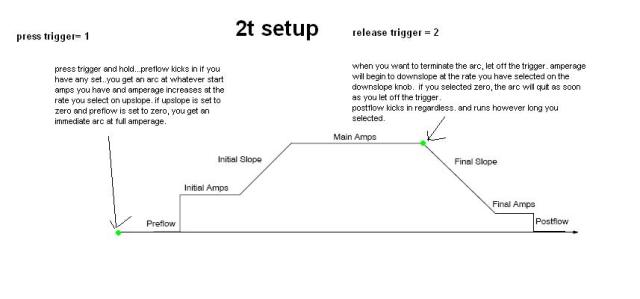

The 2t means that when you press the button , you get an arc….when you let off , the arc quits.

You have to hold the button down the entire time you are welding or the arc will quit.

The 2t setting on this primeweld is strictly as an on/off switch for tack welding or for welding thick stuff where amperage control or finesse is not needed. But the 2t setting on some welders can also be used with upslope and downslope settings to be more like an amperage control.

The image below shows a 2t setup for most tig welders that have 2t 4t settings

So what is 4t?

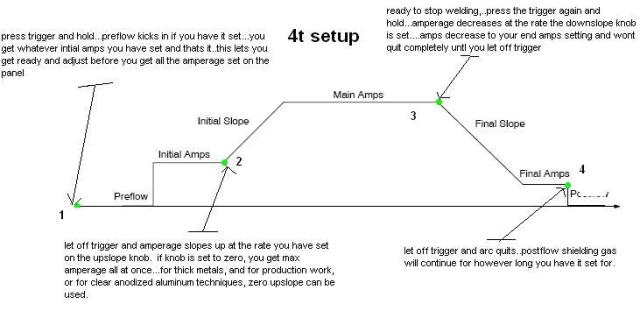

With the 4t selector knob, there are 4 switch movements that basically do the same thing as the 2t…so it gives you a little bit more control over the cycle and lets you weld with less fatigue because you can don’t have to hold the switch down while you weld.

4t is this…

Press the trigger, you get an arc of whatever amperage you set the start amps. You might want a really soft start, or you can select a crisp hot start. A zero setting will start at really low amps. That’s usually a good thing but if you are using big tungsten like 1/8”, you may get an erratic start and need to bump up the start amps to get a sure start.

So position number 1 of the 4 t’s is pressing the switch, holding it down and getting an arc…Nothing else happens on the 4t position until you let off the switch. That’s number 2 of the 4t..when you let off the switch, the upslope begins and increases amperage until it levels out at the peak amperage. When you are ready to stop welding , you press the switch and hold it down( number 3 of the 4t’s) and the downslope kicks in and decreases amperage to the point where you have set your end amperage.

But you still have an arc until you let off the switch and that would be number 4 of the 4 t’s.

Bazinga!! That’s it.

go back to tig inverter settings part 2...ac balance, and ac frequency

go back to part 1 of tig inverter settings