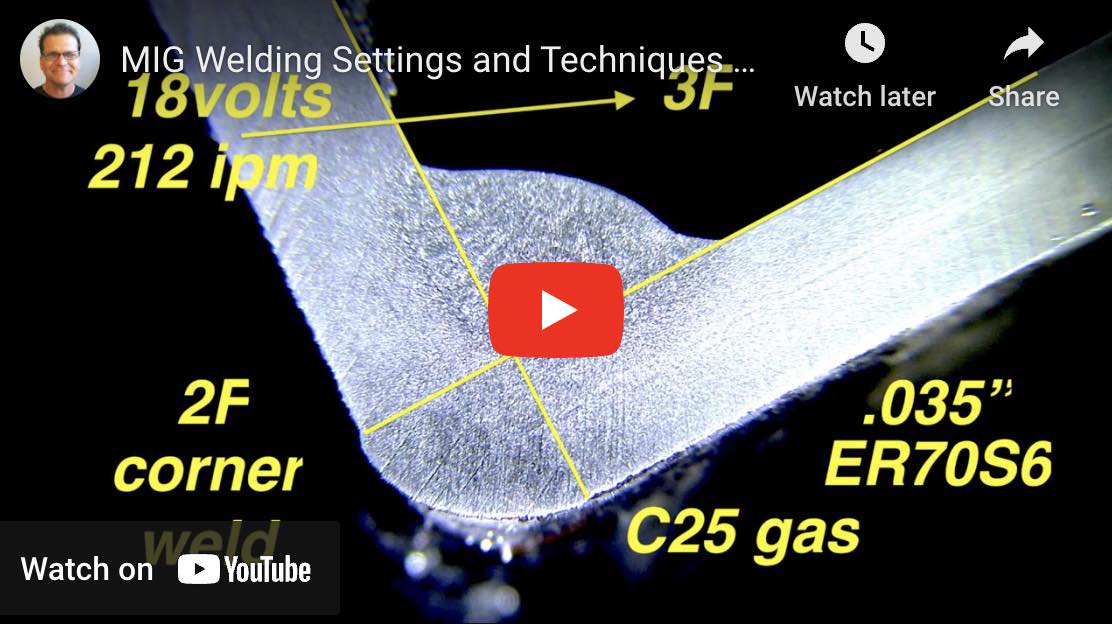

115 volt mig downhill corner weld

This is a short back to basics style video on 115 mig welding.

Corner joints are very common and up to 1/8" thick can be welded downhill with good results.

115 volt mig welders are usually capable of doing both flux core and bare wire but are only capable of short circuit transfer with bare wire...and usually use either 75/25 argon/co2 gas or pure co2 gas.

Here are the details and settings used for this joint.

material - 11ga steel (1/8") thickness

C25 gas at around 20-25 cfh

voltage 18.1

wire feed speed 149 inches per minute

.035" ER70S6 wire

I used a PrimeWeld MIG180 for this video which is a dual voltage mig welder that runs off either 115 volt or 230 volt power.

I had it plugged in to a standard 115 volt outlet on a 20 amp breaker.

I have several videos using this welder with complete settings listed on each page and you can see those here at the main primeweld mig180 page

learn more about the MIG 180 at weldmonger.com

I think of my Mig180 mostly as a Great Little MIG Welder with a great arc and nice small mig gun that feels great in my hand... but it also Stick welds, and even comes with a spool gun for aluminum.

just look at all that comes with it... That is a lot of bang for the buck!