18ga CRS Cube Project

In this video, you will see TIG welding an 18ga crs cube.

Flash Tacking with a #5 stubby gas lens cup, TIG welding with Chill Bars and without , using a Jazzy 10 ceramic cup, and plenty more.

welding procedure

Base Material Type/Thickness - 1018 cold rolled steel 18 ga

Prep Method - flap disc and acetone wipe

Filler Metal Type/Size - ER70S-2 .045"

Tungsten size and prep - 3/32" 2% lanthanated 30 degree taper

Gas Type and Flow Rate - Argon 20cfh Jazzy 10 cup

Cup size - jazzy 10 ceramic from weldmonger.com

Current/Polarity - 60 amps DCEN ....90 amps for tacks

Length of Arc - 3/32" or less

Angle of Travel - 10-30 degrees

Manipulation/Technique- dab pause

Speed of Travel - 6 inches per minute

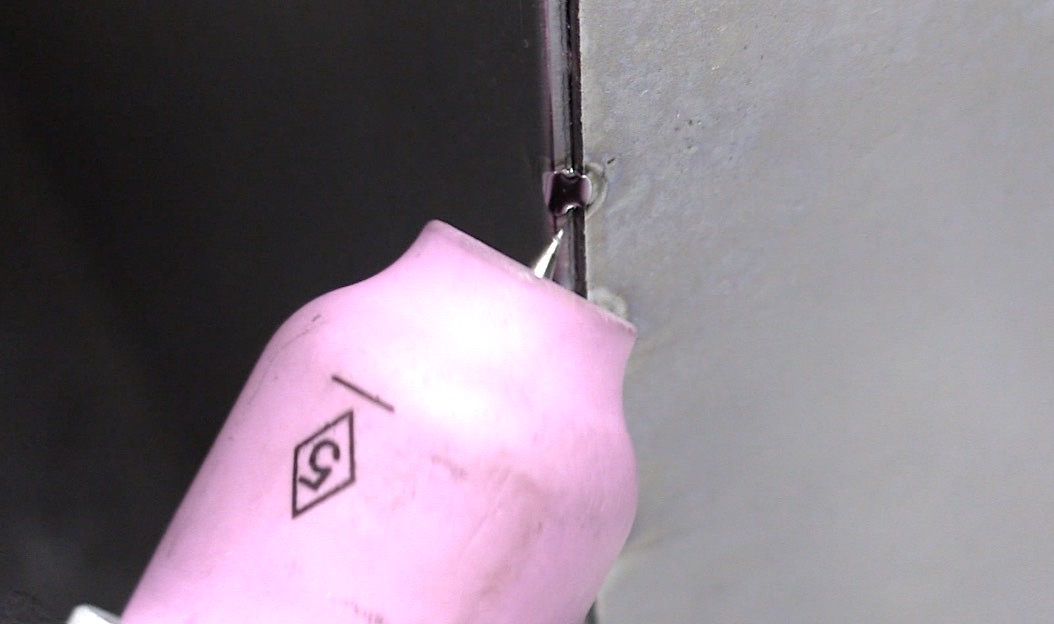

Flash Tacks

Some newer inverter style tig welders have a spot timer setting.

But flash tacks can also be done using a foot pedal or torch switch.

Amperage is set 1.5 to 20 times higher than normal welding amperage and the tack weld is blasted for a fraction of a second.

For this video, I was welding 18 ga crs which is only .048" thick.

If you follow the one amp per one thousandths of thickness rule of thumb, that would seem to indicate that normal welding amperage would be only 48 amps.

but for flash tacking, I chose to set amperage to not quite twice the normal welding amperage for 18 ga crs...

and that amperage was 90 amps.

Be sure to practice on some scrap first because 90 amps will easily blow a hole in 18 ga if you are careless.

Chill Bars

I save scrap pieces of thick aluminum for use as chill bars on sheet metal welding like this.

I have done quite a bit of work for machine shops over the years and they always have short pieces of thick aluminum they are willing to give away or sell for cheap ...so I have several different shapes.

I also made a simple outside corner tool out of copper.

Its best of you can clamp chill bars down tight so that they pull heat out of the part...but even when you cant, they still help a lot in trapping argon gas and allowing for better gas shielding.

Maybe not that important on carbon steel, but same principle applies for stainless.

Chill bars really make a difference on stainless.