3G TIG Test

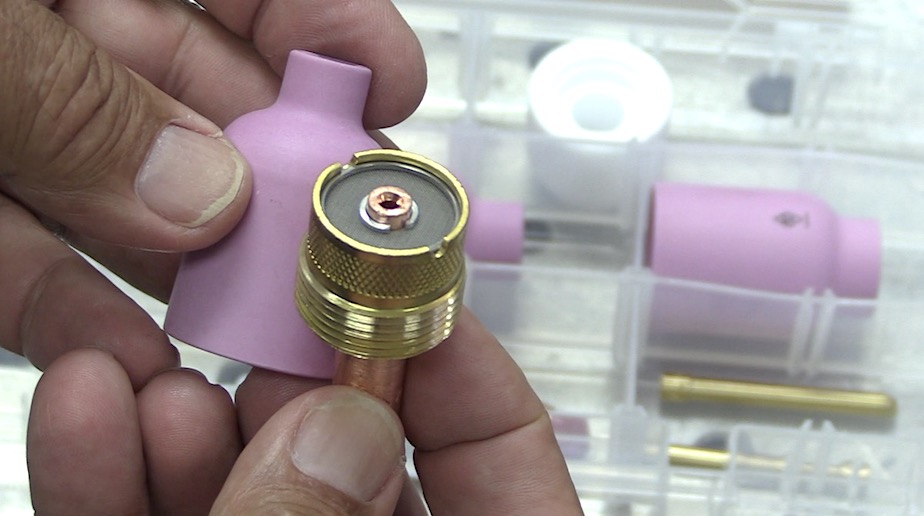

Our new LArge Diameter Gas lens kit now comes with 5/32" setup for those high amperage jobs

A 3G TIG test is usually a training exercise as part of moving on to pipe.

But it is also a legitimate test used by some shops to qualify welders for work on turntables.

The same settings and techniques that work on plate will also work on pipe provided the thickness, bevel angles, and fitup is the same.

And since plate is sometimes easier to come by than pipe for practice, the 3g tig test is a convenient way to verify settings and practice for pipe.

Fit up and joint details for 3G plate TIG test.

- Material is A36 hot rolled plate 3/8” thickness

- Mill scale removed from weld zone

- 35 deg bevels

- 1/8” gap

- Zero land aka feather edge

- 1/8” ER70S-6 filler rod

- #6 gas lens cup 20 cfh argon

- 3/32” 2% lanthanated tungsten electrode

Root pass 100 amps

There are several techniques that will work for a root pass on a 3g plate test.

A dip keyhole technique, or back feeding technique would work.

I decided to use a laywire technique for this page and video.

I set amperage to 100 for the root pass

For the first portion of the root pass I freehanded using my TIG Finger® using a forward and back technique with no side to side motion at all.

This technique seems to help push the root thru the back and adds a bit of reinforcement.

For the second part of the root, I walked the cup.

Some might get technical and differentiate between walking and wiggling the cup but I call it all walking the cup.

It is true that once you get out to the cover pass and no longer have a bevel to work with, the technique changes a bit.

Walking the cup on a cover pass is akin to walking a 55 gallon drum across a shop floor.

Hot Pass 111 amps

A hot pass is sometimes done with higher amperage than the root but not always. A good example would be when a j bevel is used on pipe.

The main goal for the hot pass is to not suck back or remelt the root.

If you set amperage to high for the hot pass, and get hung up a bit, you can easily melt thru and get suck back.

So I set the amperage only 11 amps hotter to 111 amps for the hot pass

For the first half, I freehanded using my TIG Finger® and for the second part of the hot pass I walked the cup.

Fill passes and Cover pass

The full length video is at welderskills.com along with over 700 other videos on everything from repairing heavy equipment to advanced TIG settings for aluminum.

We have a special deal set up for you right now where you can get 1 month membership to welderskills.com for only 1 dollar.

There is a great community of welders at welderskills who take their trade seriously and who participate in our live podcast calls and get answers to welding questions.

Invest in yourself and get better along side us. Iron sharpens Iron.