3g Weld Test - How to pass

A 3g weld test welded with 7018 is the most common and is often given along with a 4G test.

Scroll down for Dual Shield and GMAW-s 3g tests

A 3G weld test with 7018 stick electrodes is commonly 3/8" thickness with 22.5 degree beveled plates and a 1/4" thick backing strap. Thickness of test plate can also be 1 inch or greater depending on scope of job.

For more videos on passing welding certification tests ...

Another Common 3G weld test is Dual shield flux core also known as gas shielded flux core

A 3G weld test using Dual shield flux core also known as gas shielded flux core is also commonly 3/8" thickness with 22.5 degree beveled plates and a 1/4" thick backing strap

You might also need to know how to pass a 3G mig test

A 3G test using MIG aka Gas Metal Arc Welding could be short circuit mig, or pulse spray mig and is often 3/8" thick plate with 37.5 degree bevels with an open root.

The root might be downhill or uphill and is usually gapped at around 1/8" root opening.

3g weld tests are sometimes x rayed but are often bend tested by cutting one root bend strap and one face bend strap.

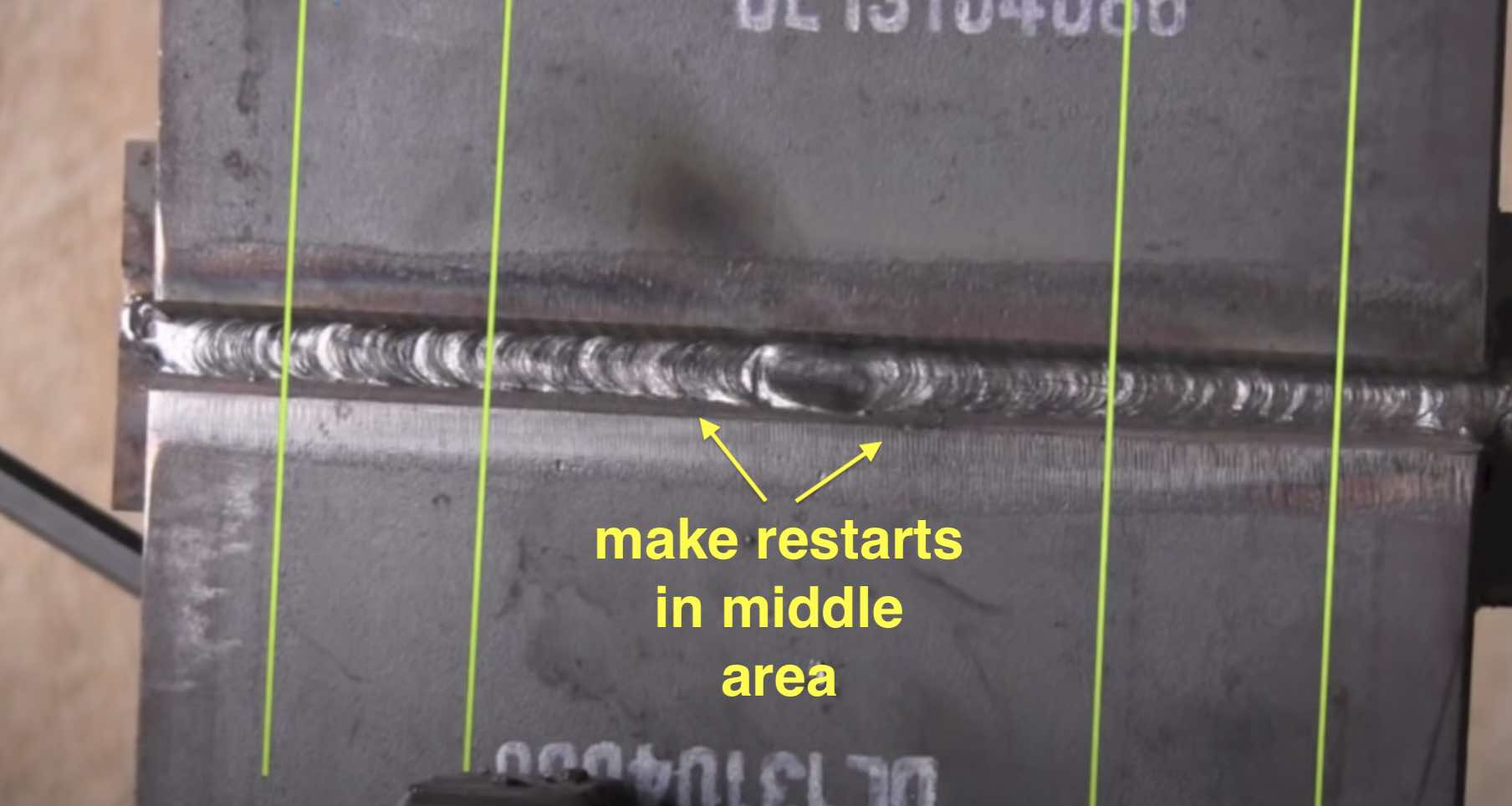

For a bend test, you don't want restarts right on a bend strap

Pro tip: plan ahead and make any restarts in middle area so that restarts wont be on bend strap areas

Some best practices for any welding test

- Review welding codes and standards: Familiarize yourself with the relevant welding codes and standards that apply to the test. These may include codes such as AWS D1.1 (Structural Welding Code - Steel) or ASME Section IX (Welding and Brazing Qualifications).

- Read and comply with the WPS ( welding procedure specification)

- Ask the test supervisor "are there any additional requirements I should know before I start". Welding inspectors and welding test administrators all have their personal preferences. Asking this question might give you a little insight into some pet peeve or preference they have.

- Clean mill scale back at least 1/2" from weld area ..that will help you avoid undercut.

- Take extra care on the fit up. Structural welding plate tests per D1.1 usually have a gap requirement of 1/4" +- 1/16". As far as ensuring penetration on the root pass goes, a wider gap usually helps so I recommend making sure to have a full 1/4" gap that is even from one end to the other.

- Sometimes there are time limits so plan your work and work methodically. But don't rush. let the piece cool a bit before the cover pass.

good luck welder,

Jody