5G Weld Tests

5g downhill 12 inch pipe with 5/32" 7010 root and 3/16" fill and cap

- HOME

- WELDING CERTIFICATION

- 5g Weld Tests

in this video you will see a 5g pipe test welded to API 1104 code. Andrew Cardin followed the weld procedure used by his employer NEUCO. 12" pipe 30 degree bevels with 3/32" gap and 3/32" land. 5/32" xx10 root with 3/16" xx10 fill and cap.

5G pipe root

the video below is on the root pass only because for some folks, thats all they need help on

5G mig pipe

a fairly common test for pipe shops is a 5G pipe with downhill open root followed by uphill fill and cap passes.

Miller Electric even has a system they call the Miller Pipeworx 400 that is specifically designed for open roots as well as fill and cap passes on pipe for pipe shops.

In pipe shops, the root pass is often welded downhill using either short arc mig or RMD (raised metal depostion) mig and the fill and cap passes are often welded using pulse spray mig.

On some jobs like power plants and paper mills, 5g is the most commonly welded pipe weld.

Boiler tubes are most often in the 2g position.

So why then is the 6G position used for welding certification tests?

Because a 6g test provides for a wider range of qualifications than a 2g or 5g test.

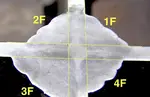

A 5G weld test is a way to check a welder's skill in overhead, vertical, and flat positions all in one pipe test.

- Positioning: In a 5G weld test, the "5" means the joint is positioned at a where the axis of the pipe is horizontal. The "G" stands for groove weld, where the weld is made in a beveled groove where the bevel angle is specified by the applicable procedure or code.

- Challenge: Welding in the 5G position is considered a bit tricky because its done in a fixed position, making it harder to reach and weld all around. It tests the welder's ability to work in different directions – vertically, horizontally, and overhead and that requires constant body positioning all while maintaining a steady arc length and rod angle.

- Skills Tested: During the test, the welder needs to control the welding torch or electrode carefully, manage heat, and produce a weld that meets specific quality and visual inspection standards.

- Evaluation: The weld is visually inspected first and then either bend tested or x rayed to verify soundness and to ensure it meets the required standards for internal defects. Passing the 5G weld test demonstrates that the welder has the skills needed to tackle welding jobs in challenging positions like vertical and overhead angles.

more 5g weld test videos coming soon...