7014 Welding a Multipass Tee Joint

scroll to bottom of page for a more basic stick welding video

7014 Welding Rods are a good rod to have in the box.

Especially when you need to deposit a fairly heavy bead.

for this video, I showed a multipass weld on a Tee joint.

the amperage range for a 1/8" 7014 welding rod is around 100-150 amps.

For this video, I used around 125 amps on DCEP.

One of the best features of a 7014 rod is that it can be used on all polarities. DCEP, DCEN, and AC.

That is a good thing for folks who only have an AC welder.

7014 welding rods have a puddle that compares to a 6013 rods except that 7014 rods have a heavier flux coating and therefore make a bigger puddle.

7014 rods are NOT considered a low hydrogen rod.

And that means basically 2 things...

- They dont require an oven

- they should not be used where low hydrogen electrodes are specified.

I used 125 amps to weld a total of 6 passes.

- Root

- 2 passes stacked over the root

- 3 passes stacked over 2 passes

Things to keep in mind for 7014 welding rods

While 7014 rods do not require being kept in a oven, they weld a lot better if they are either freshly opened, or fresh out of a rod oven.

Slag chipped off a lot easier when I used rods freshly out of the box.

using a lot more drag angle that what is recommended by books works better in pushing the slag to the rear of the puddle.

not rod manipulation is needed...this is a drag rod

CLAMS

an easy way to remember 5 main things that affect stick welding is the word CLAMS.

- Current - not only amperage but polarity. I like using 7014 using AC but for this video i used DCEP

- Length of ARC - happiness is a tight arc..usually.

- Angle of electrode - 7014 rods have quite a bit of iron powder in the flux coating and using a lot of drag angle seems to help push the molten slag to the rear of the puddle.

- Manipulation of electrode - 7014 is considered a drag rod and no real manipulation of the rod is needed although slight movement works fine.

- Speed of travel - travel speed mainly depends on the application...if the metal is borderline too thin for the rod, sometimes a faster than normal travel speed is required. For this multipass tee joint, a fairly slow travel speed was used.

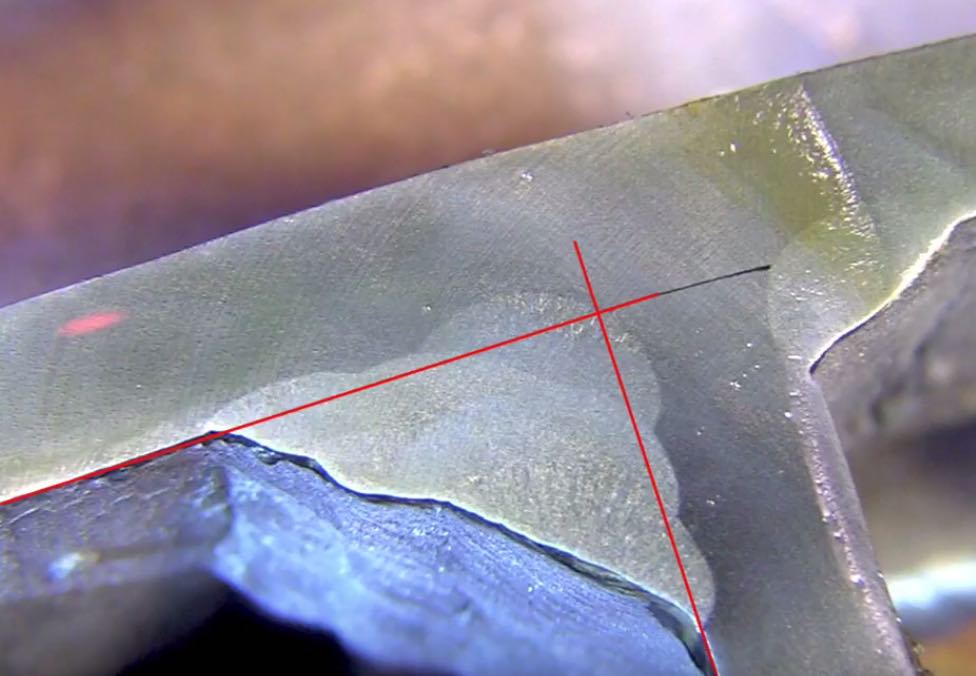

Cut and Etch 7014 multipass

7014 rods are considered medium penetration rods.

So its always interesting to test to determine if my amperage and technique worked.