Aluminum Corner Joint

...Introducing the New WeldMonger Challenger TIG kit that includes the most frequently used Cups.

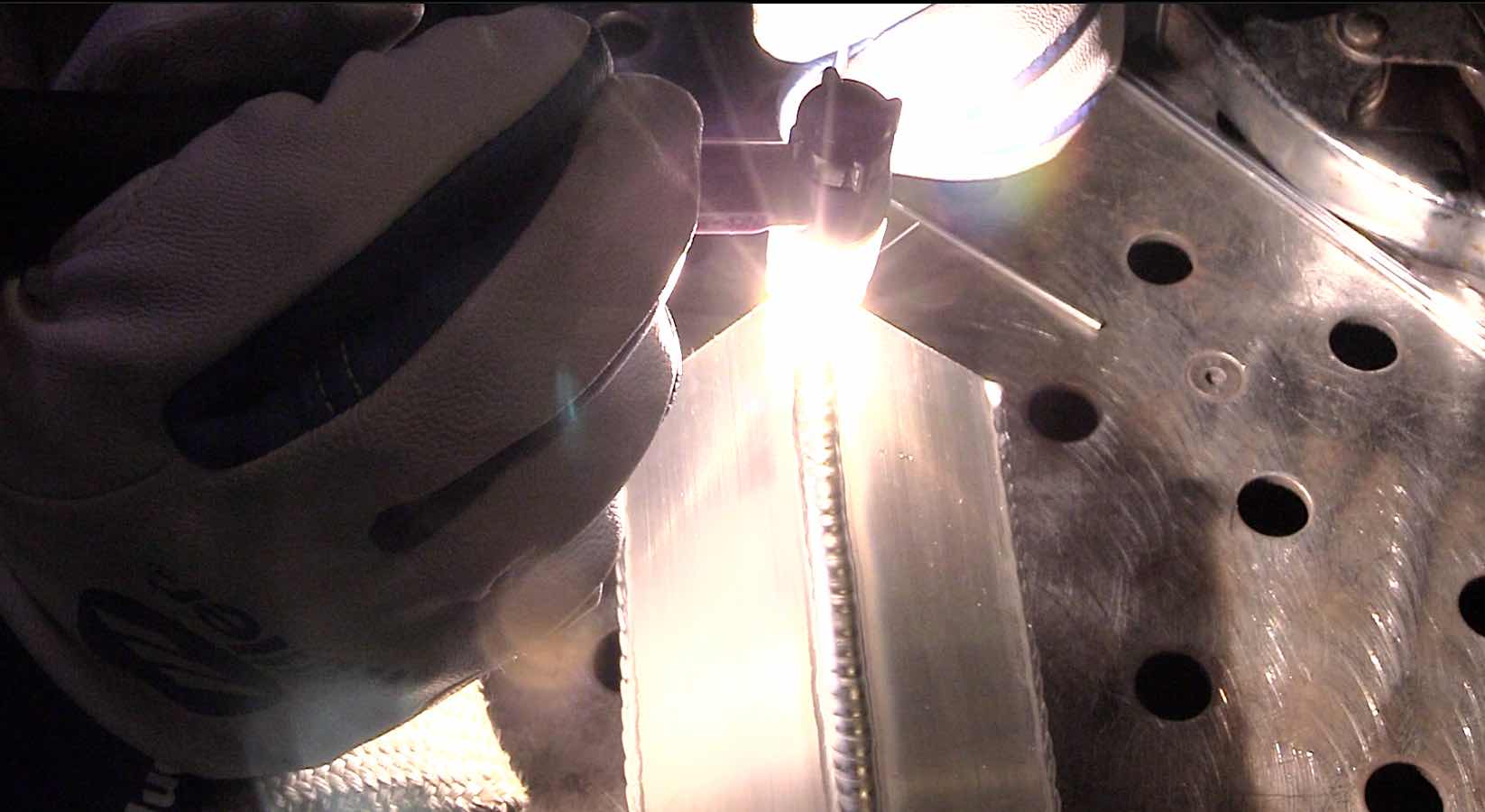

This is an exercise on TIG Welding Aluminum Corner joints on 11ga 6061 t6 aluminum.

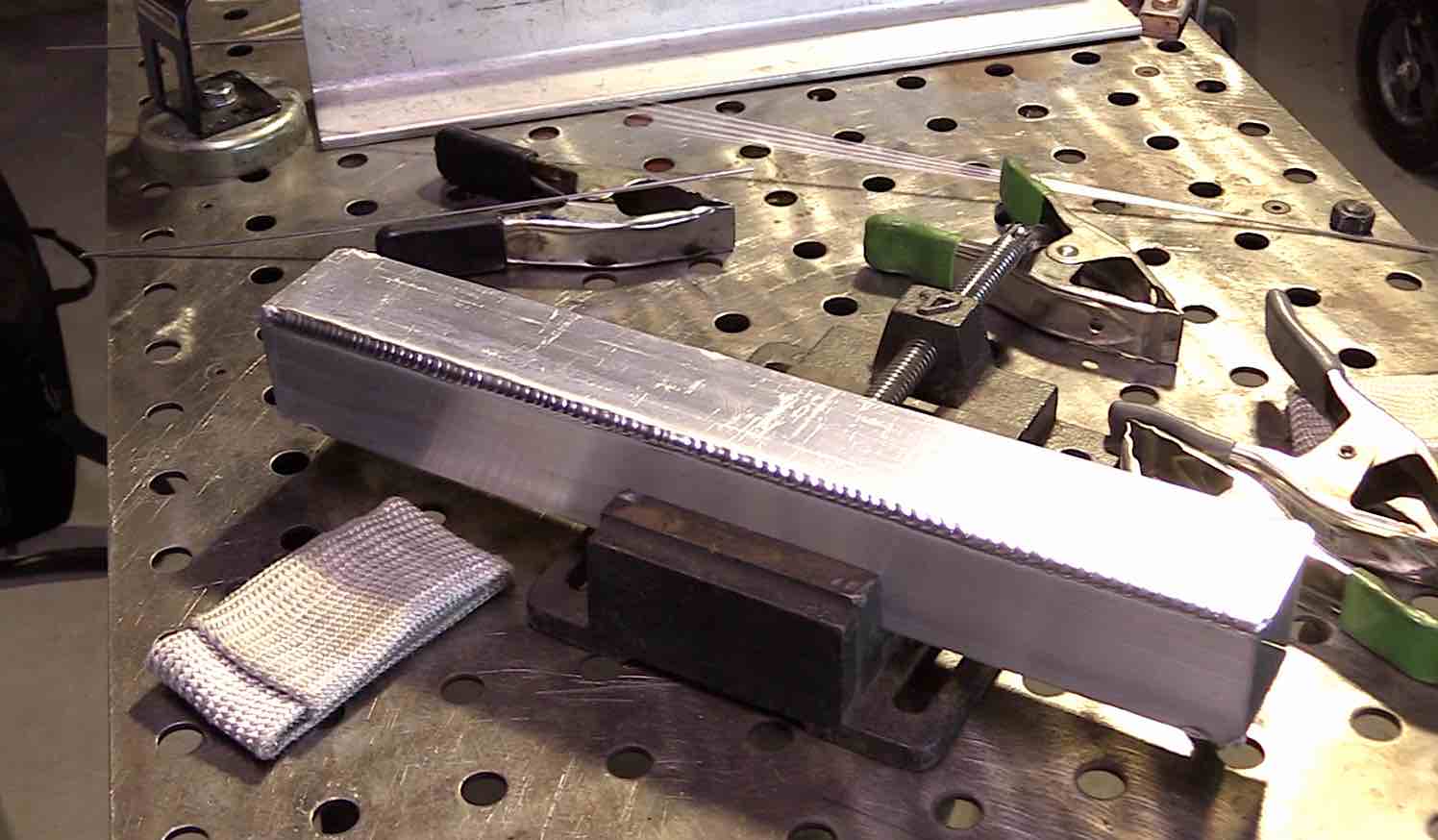

I used 2" bar stock.

In order to get the most out of the metal, I tack welded 4 pieces to make up a piece with 4 outside corner welds.

TIG welder settings

I used my Dynasty 280 dx and set the AC frequency to 120hz and AC balance was set to 69% EN.

Amperage was set to 151 (round numbers are harder to remember) and I used the wireless foot pedal.

I used 3/32" 2% lanthanated electrode along with 4943 filler rod 3/32" also.

I also used a #8 furick pro clear cup to help with filming.

The #8 furick cup really helps to light up the weld area which helps make for a better video as well as helping me see everything around the weld.

Amps on the machine read out at around 128 but I like to have a bit of extra amperage just in case.

why 4943 and not 4043?

4943 is a relatively new filler metal rod which is similar to 4043 but has better mechanical properties and will respond to heat treatment.

I got several pounds from my local welding supply as a free sample and I have been using it for lots of different applications like aluminum castings, projects, etc.

what is the difference in 1F and 2F positions?

Technically, 1F is flat position where the outside corner joint is facing straight up with each member at 45 deg.

2F is horizontal where one member is vertical and one is horizontal

There is just not much difference when it comes to technique.

Its just a terminology thing. 1F is a flat fillet weld, 2F is a horizontal fillet weld, 3F is vertical, 4f is overhead.

When it comes to tig welding, gravity is not a very big factor like it is with mig, stick, or flux core.

Ripple spacing

Which is better? wide spaced ripples...or tight ripples?

In my opinion, neither is better.

For the most part, ripple spacing is a matter of personal preference.

Application, customer or code requirements, and personal preference all play into the ripple spacing.

For me, production speed is also a factor.

Its easier to go faster with fairly wide ripple spacing.

I generally aim for about 1/8" ripple spacing.

That means in my minds eye, I am trying to move the torch 1/8" in between filler rod dips.

while that has worked for me pretty well, some jobs require a different method.