Brazing with TIG

- HOME

- TIG WELDING

- Tig Welding

- Brazing With Tig

Brazing with TIG today on some 11ga carbon steel lap joints.

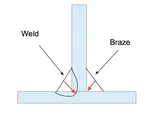

TIG brazing is a very useful process that can be used to join carbon steel to brass, carbon steel to copper, copper to brass, and even stainless steel to copper.

Brazing with TIG with any of the metals listed above usually involves either silicon bronze or aluminum bronze filler metal.

Silicon bronze is not nearly as strong as er70s2 or 6 tig filler metal but is still useful and is used for a lot for specific applications like wear pads, building up hammer faces so that they don't mar stainless steel parts, filling in thin worn areas on thin wall tubing, handles and hinges on industrial furniture, and welding art projects.

Tips for Brazing with TIG with Silicon Bronze or Aluminum bronze filler metal

- Clean the metal and remove all mill scale, paint, coatings, oil, etc. by using an abrasive followed by solvent like acetone.

- wipe filler metal down with acetone and use emory cloth if it is oxidized

- use a gas lens cup like a Furick Ceramic #12 (argon prevents an oxidized surface and helps the silicon bronze filler metal flow better)

- pulse settings of around 1 pulse per second with 30% background and around 40-50% pulse width usually provides good results

- Dont overheat. stop and let cool often

- taper amperage very slowly at the end of each bead to prevent a crater