A ck17 tig torch With a Super Flex Cable is like Butter!

- HOME

- TIG WELDING

- Ck17 Tig Torch

Have you tried a CK17 TIG torch yet?

I know not everyone has the opportunity to try out all different brand and types of tig torches like miller, esab, lincoln, weldtec, and CK.

I have.

So you can believe me when I tell you that a CK17 TIG torch with a super flex cable is a nice tig torch...especially for a 200 amp and under tig welder.

I am sure thats why brands like HTP and Primeweld include a ck17 tig torch with their TIG machines. They know the CK torch makes a great impression.

One of the main complaints with imported tig welders like Everlast, Longevity, and even Esab, is that the tig torch included with the tig welder is not always that great. (some are getting better now)

The last Esab Rebel I used had a fairly decent 17 style air cooled torch but the torch cable was so stiff, it felt like a garden hose in the wintertime... and it was fighting against my every movement.

I was tired after an hour of welding.

HTP and Primeweld are smart for including a ck17 tig torch with super flex cables with their tig welding machines.

Imagine if you just bought a new "up and coming" brand of sports car that had plenty of power, handled great too, but the steering wheel just felt cheap and clunky and smelled like Harbor Freight.

You would be thinking to yourself, Dang...this car is pretty awesome,

...but I just cant get past the clunky feeling of the steering wheel.

That car company would be foolish to have a the steering wheel, the main touch point of their awesome sports car ... to feel cheap and clunky.

They would be so much better off paying extra attention to the steering wheel...even if it costs a few bucks more... so it wouldn't detract from the overall experience.

When I worked as a pipe welder, I had to pretty much be ok with whatever tig torch they provided.Mostly it was 17 and 26 style air cooled torches with a valve because they we used mostly scratch start tig rigs.

I got used to them.

But when I transisitioned into aerospace repair welding, almost every tig torch was a small water cooled 20 style torch.

And then I got used to those.

I still prefer a small torch for the most part, but I learned that ck17 tig torch with super flex cable feels great too.

But only after I swap out the standard torch hardware to a furick or ck stubby gas lens setup.

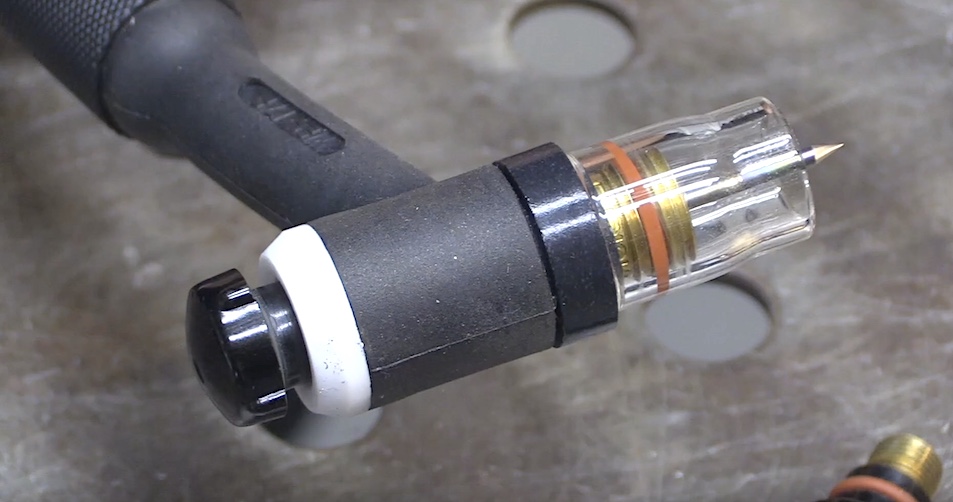

My every day "go to" setup is a CK17 Tig Torch with super flex cable and a clear #7 or #8 cup with furick adapter hardware

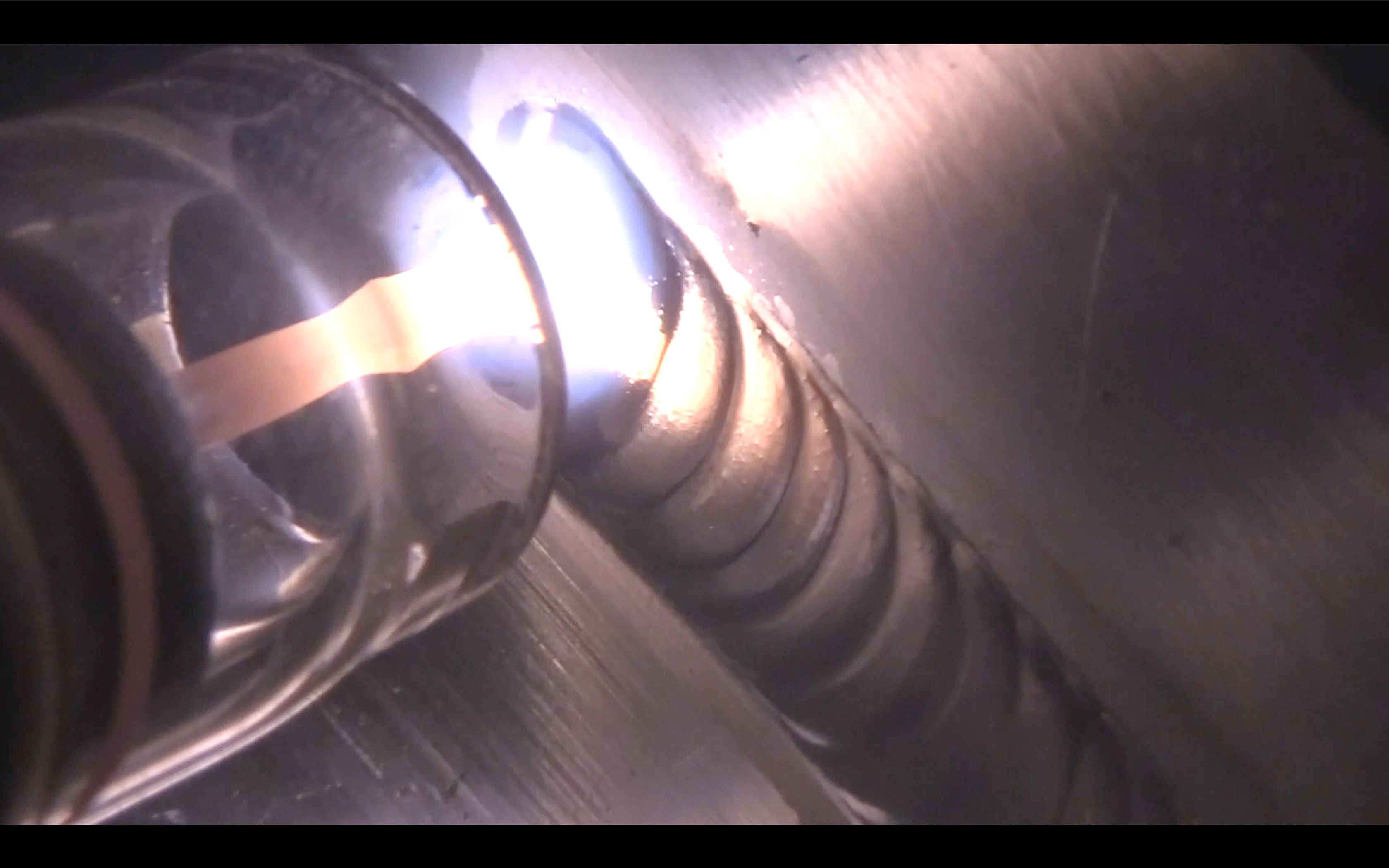

A clear 7 or 8 a great all around setup for AC and DC and it lights things up for me and helps me see everything better.

I like to use the same CK17 torch with a pink ceramic #5 or #6 cup for aluminum up to 1/8" thick.

For thicker aluminum, my go to setup is a water cooled CK20 tig torch with super flex cables

And for stainless steels, and 4130 chromoly, I like to use a ceramic jazzy #10...or a Furick ceramic 12 cup.

Transitioning from pipe welding to aerospace welding

In pipe welding, tungsten electrode size was usually 1/8"...( sometimes 3/32") with mostly either 17 or 26 style air cooled torch.

In aerospace welding, tungsten size was usually 1/16" (but we sometimes used up to 5/32" for heavy aluminum and magnesium castings)

Everything was smaller in the aerospace welding world including filler metal.

Before an Aerospace career, I never even used a small .030" filler. ...but .030" filler metal is very common in aerospace welding.