Depth of Fusion

An often misunderstood topic is Depth of Fusion.

Fusion according to the American welding Society (AWS) is "The melting together of filler metal and base metal (substrate), or of base metal only which results in coalescence"

Depth of fusion is defined as “The distance that fusion extends into the base metal or previous pass from the surface melted during welding” (see ANSI / AWS A3.0 Standard Welding Terms and Definitions)

Shallow depth of fusion and lack of fusion

The joint pictured above is a short circuit mig fillet weld on a36 steel.

There is obvious lack of fusion as evidenced by the straight dark line at the root...but there is also some shallow depth of fusion here and there.

this is a common problem with short circuit mig where mill scale was not removed and settings and technique were off.

Cleaning mill scale, correct contact tip to work distance ( ctwd) also called "stickout", gun angle, and using established settings....

All go a long way in achieving adequate depth of fusion and penetration.

Aluminum .063" tee joint fillet weld 6061 t6 welded with 4043 filler

The joint pictured above is an aluminum tee joint. .063" (1.6mm) thick 6061 base metal welded with 4043 1/16" (1.6mm) filler metal.

Even though this joint appears to have zero depth of fusion, it was surprising how it performed in a bend test.

The straight line indicates very little depth of fusion but it is not easy to determine exactly where fusion occurs.

4043 wire has a solidus temperature of 1,065 degrees F and a liquidus temperature of 1,170 degrees F, or a melting range of 105 degrees F

The wide melting range of 4043 filler rod can set up a situation where the filler metal melts and bonds to the base metal with little or no depth of fusion...and also creates a situation where the fillet can exhibit straight bond lines that appear to be a brazed joint with little or no depth of fusion.

So basically fusion can occur within just a few molecules but depth of fusion (penetration) can go much deeper.

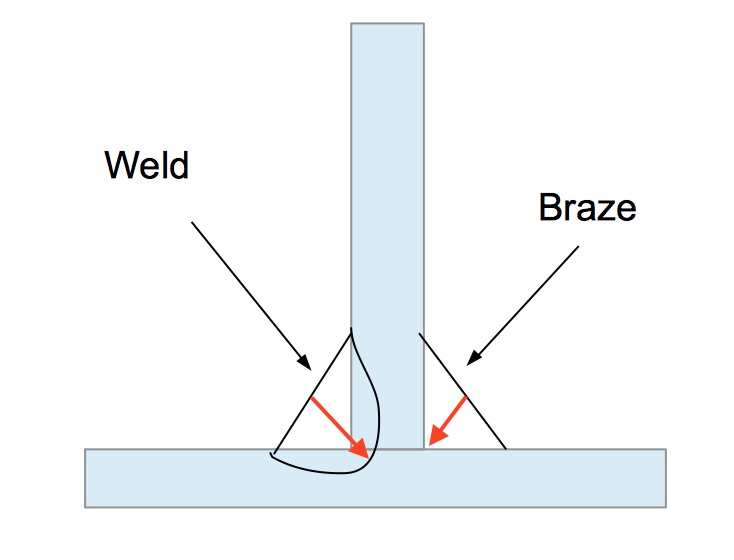

Think of a braze or solder joint with a fillet.

If you were to

cut a cross section of the joint and polish and etch it and examine the

fillet under magnification, the fillet would resemble a right triangle.