This page is about Duty Cycle...but first...

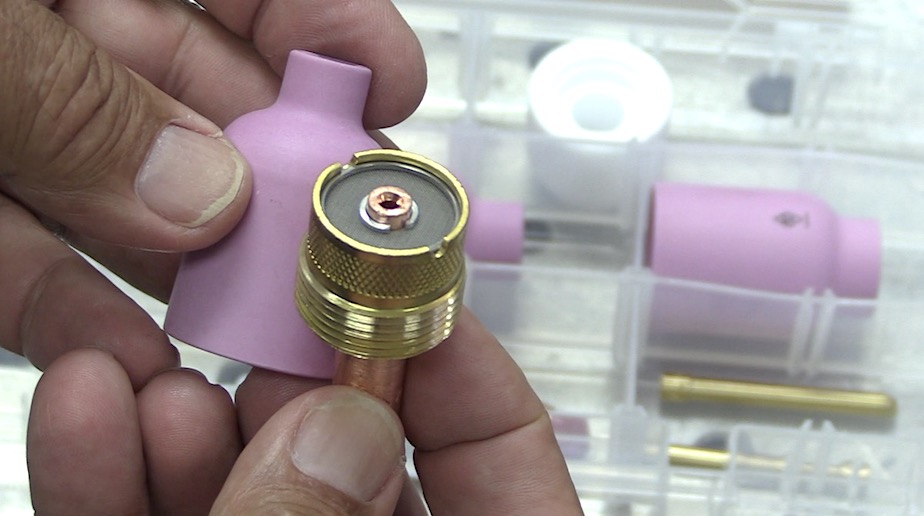

...Introducing the New WeldMonger Challenger TIG kit that includes the most frequently used Cups.

What is Duty Cycle in Welding?

Short welds on square tubing can be done with a very low duty cycle, but If you are TIG Welding lots of build up beads on aluminum, Duty Cycle becomes more important.

So What Exactly is Duty Cycle and why should you care?

The term “duty cycle” refers to the percentage of time a welding machine can weld continuously in a 10 minute period and at a certain amperage …and in a 104F degree environment…before it needs to cool off for the rest of the 10 minutes.

Our new LArge Diameter Gas lens kit now comes with 5/32" setup for those high amperage jobs

Duty Cycle is usually listed as a percentage at a certain amperage.

So a 60% duty cycle at 140 amps means you can weld for 6 minutes straight at 140 amps before you need to let the machine rest for 4 minutes. ( that’s just an example because with stick welding, there is a break between switching electrodes)

Duty cycles can differ between different processes too.

For example the CK worldwide MT200 AC DC tig welder lists duty cycle at 25% at 200 amps for TIG. And 30% at 160 amps for stick welding

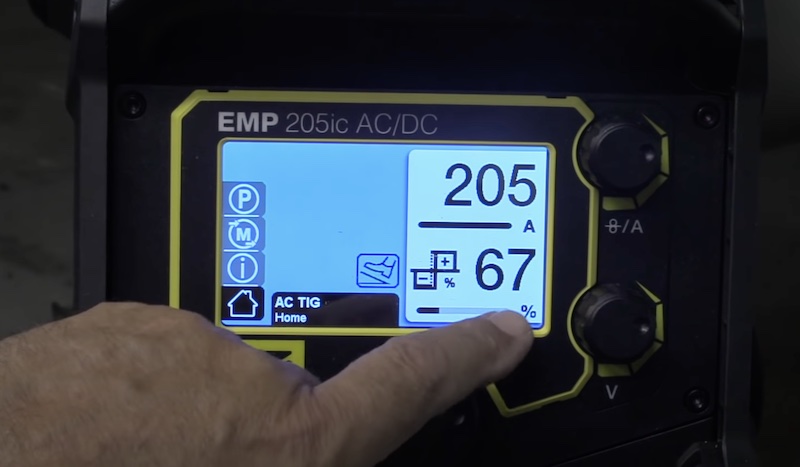

While the Esab Rebel 205ic AC DC multiprocess welder lists duty cycle at 25% at 205 amps for TIG and only 25% at 170 amps for stick welding.

Another thing that affects duty cycle is Fan on Demand Feature available on some welders.

Since I have used several different brands of welders over the last few years, I have noticed a trend of really loud cooling fans.

I really think loud cooling fans are a result of trying to state as high a duty cycle as possible.

Older transformer machines typically used one large fan and while it made some noise, it was tolerable and sounded more like a house fan.

Newer inverter design machine often utilize small computer type cooling fans with a higher pitch noise and it can be very annoying..it can wear on you after a while. IMHO

What is ‘Fan on Demand”

Some welders like the ck mt200, have true fan on demand where the cooling fan only kicks on when the internal temp of the machine exceeds a certain level. Then the fan turns back off once the machine cools down.

My very first encounter with “fan on demand” was with a Miller Syncrowave 250 and I thought it was genius.

It made a lot of difference in the overall noise level in the shop where I worked.

I liked that machine so much I bought one for myself….wish I still had it but it took a 100 amp breaker so when I moved out of a shop and into my garage, I sold it and got a Dynasty 200 that also had true fan on demand.

Some tig welders have a very loud cooling fan that runs all the time.

The Esab Rebel 205ic ac dc welder for example, has a very loud fan…one of the loudest I have ever heard, and it kicks on after you strike the first arc and continues to run for a very long time before shutting off …even if you are just tack welding thin sheet metal at low amps. It welds ok, but that Fan is so loud.

Additional tips about duty cycle:

• When welding at lower outputs, duty cycle increases.

• Duty cycle is evaluated at a specific ambient temperature. Usually 104 F. If the ambient temperature is cooler, duty cycle improves.

• for multi-process machines that run on multiple voltages , duty cycle and welding output will vary by process and input power.

Why should you care about Duty Cycle?

If the type of work you do is causing your welding machine to shut off from thermal overload, thats a time waster and cant be good for the machine either.

I myself have pushed a dynasty 200 wide open on a job where it shut down from exceeding the duty cycle. And of course, it was a rush job.

( this is where you want a higher amp welder with a higher duty cycle and also a water cooled tig torch)

So what is the bottom line on Duty Cycle?

A higher duty cycle is great to have but typically, machines with higher duty cycles cost more.

It really depends on what you are going to be doing as to how high a duty cycle you need.

For example, production welding one part after another high amperage without much rest would require a higher duty cycle.

While Tig welding a 4130 chromoly .030” wall thickness tubing airplane could easily be done with a lower duty cycle.