Gas metal arc welding overview with videos

learn more about the MIG 180 at weldmonger.com

learn more about the primeweld mig180 at weldmonger.com

Gas Metal Arc Welding (GMAW), also known as Metal Inert Gas (MIG) welding, is a popular and versatile welding process used in various industries. Here are some important things to grasp about GMAW:

- Process Overview: GMAW involves a power source ( frequently called a welding machine), a wire feeder mechanism, a MIG gun, and a shielding gas. The wire is not only the filler metal but is also the electrode. Whe you pull the trigger on a mig gun, three things happen all at once. The shielding gas flows, the arc starts, and the wire feeder starts feeding wire and all that works together to melt the base metal and consumable electrode wire. The shielding gas is used to protect the weld from atmospheric contamination.

- Shielding Gas: The choice of shielding gas for GMAW depends on several factors because there are different modes of GMAW. The 2 most common modes are short circuit mode and spray. Short circuit is widely used for general fabrication and for welding in all different positions. Spray is more common in production applications and is much hotter than short circuit. Common gases for short circuit include argon, carbon dioxide, and mixtures of these gases. 75argon/25co2 and pure CO2. For spray mig, a higher percentage of argon is used and common mixtures for spray transfer include 90argon/10CO2, 95argon/5CO2, and even some mixtures like 98argon/2% O2.

- Electrode Wire: The consumable electrode wire is fed through the welding gun and is continuously melted to form the weld bead. Wire materials and diameters can vary depending on the application and the metals being welded. The most common wire for carbon steels is ER70S6

- Polarity: GMAW is almost always done using Positive (DCEP) polarity. this is often overlooked on small 115 volt mig welders because they are often also used for flux core welding which typically requires DCEN polarity.

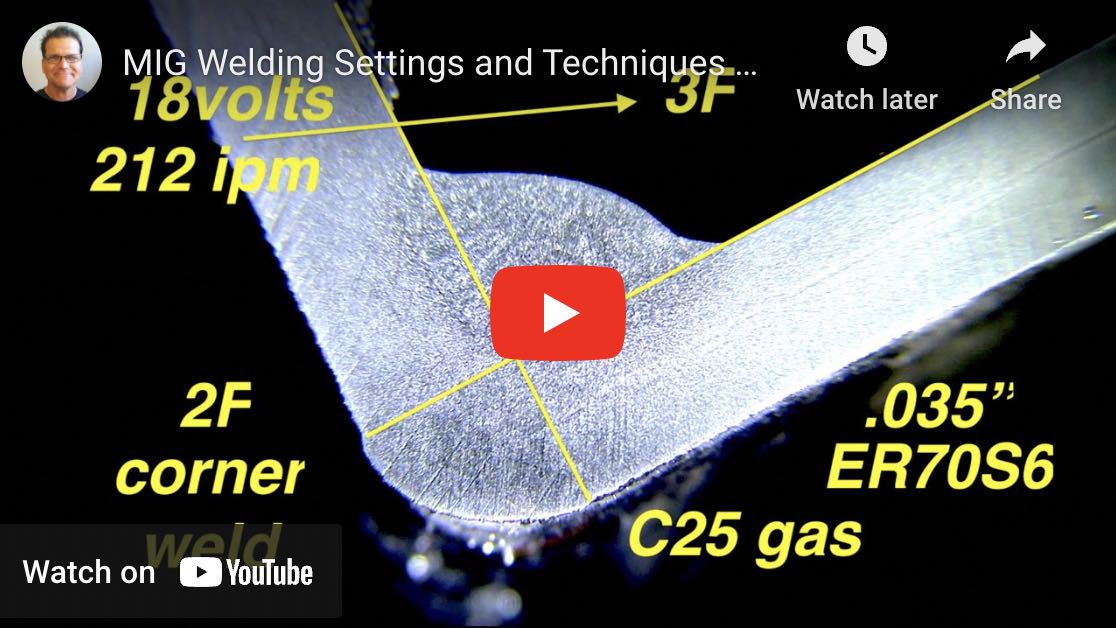

- Wire Feed Speed and Voltage: Proper balancing of wire feed speed and voltage is essential for achieving the desired weld quality and penetration. These parameters affect the heat input and deposition rate. MIG settings are usually provided on a chart on the inside of the wire feeder but can also be found at sites like millerwelds.com in the form of a weld calculator. There are also many short videos here at weldingtipsandtricks.com showing settings for all positions, joint types, and thickness

- Welding Position: GMAW can be performed in various welding positions: flat, horizontal, vertical, and overhead. But spray transfer is too hot for vertical uphill welding. Proper technique and adjustments are required for each position to achieve consistent and high-quality welds.

- Joint Preparation: Proper joint preparation is important to ensure good weld penetration and strength. Mill scale coatings on thick hot rolled steel can prevent good even penetration and should be removed for best results. Lighter mill scale as you see on square tubing is much easier to penetrate but clean metal will almost always yield better results. Bevels, grooves, and other preparations may be necessary based on the joint type and material thickness.

- Welding Technique: Maintaining a consistent travel speed, angle, and distance between the electrode and the workpiece is essential for achieving uniform and strong welds.

- Applications: GMAW is versatile and can be used to weld a wide range of materials, including carbon steel, stainless steel, aluminum, and other alloys. It is commonly used in automotive, aerospace, construction, and manufacturing industries.

- Advantages and Disadvantages: GMAW offers high deposition rates, ease of automation, and suitability for a variety of materials. However, it is not as clean or precise as TIG welding. GMAW may produce more spatter compared to other processes and requires careful control of shielding gas and welding parameters.

- Safety: As with any welding process, safety is paramount. Proper personal protective equipment (PPE), ventilation, and fire prevention measures are essential when performing GMAW.

GMAW is often considered an easy process to learn and while there is a grain of truth to that.... getting really good with GMAW requires practice and experience. Proper training and guidance from experienced welders or instructors is highly recommended.