Handheld Laser Welder

- HOME

- TIG WELDING

- Handheld Laser

Handheld lasers are here to stay.

They will not replace TIG welding completely because a TIG welder is more versatile and much less expensive, but for certain jobs where long runs are needed on stainless and aluminum sheet metal, handheld lasers make a lot of sense.

Welding a stainless lap joint with a handheld laser

I visited DenaliWeld Laser near Chicago and got a close up demo on the capabilities of hand held lasers on stainless steel and aluminum.

I was super impressed at the speed and appearance.

Ok so laser welds are pretty. But a pretty weld is no good if its not strong.

What about penetration?

I like to do macro tests on welds to check for penetration so I took the welds back to my shop and tested them

Cut and Etch results

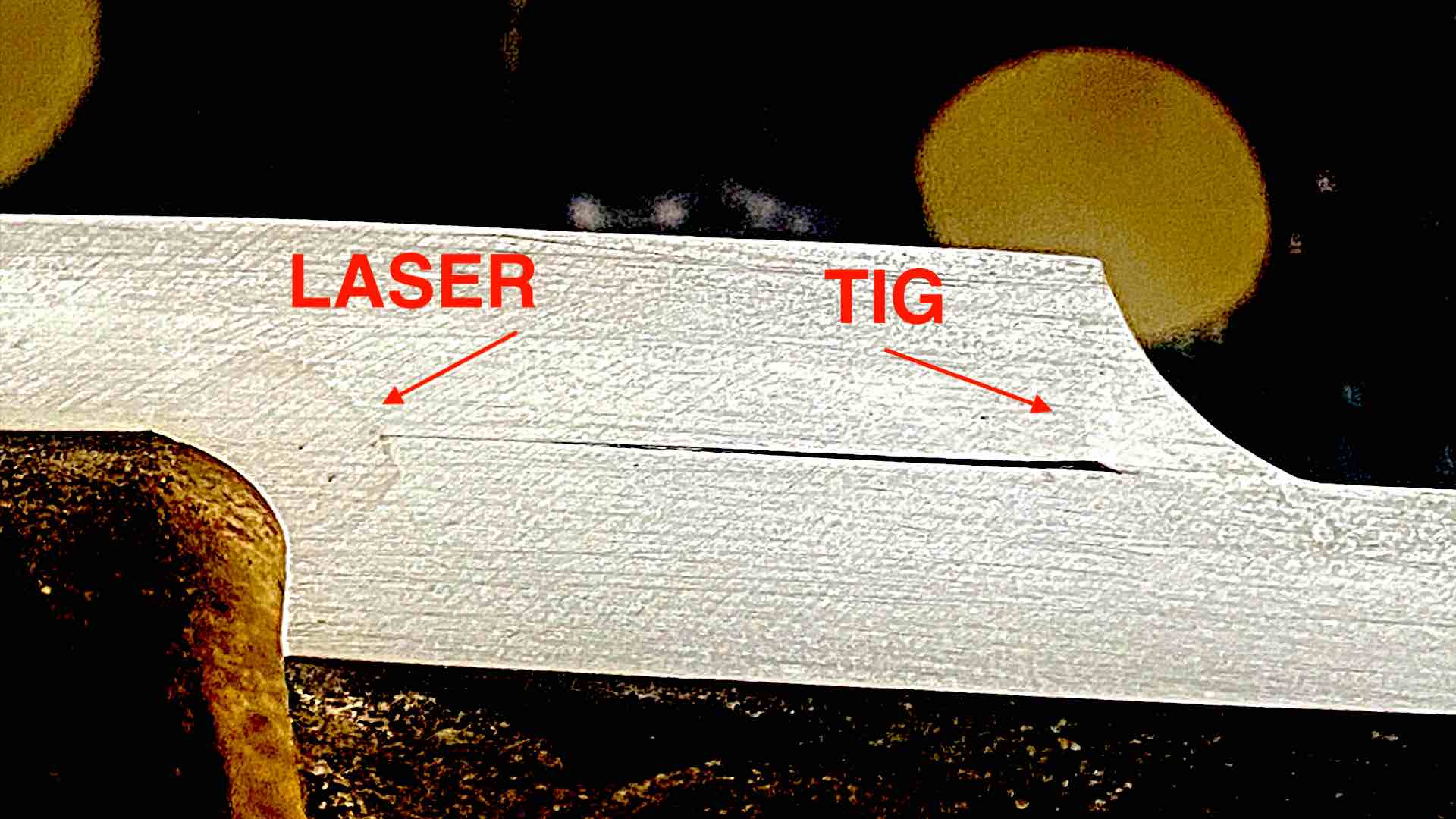

Aluminum laser weld vs TIG

The stainless steel lap joint sample showed adequate penetration.

The weld just barely hit the root but that is pretty normal for .080" stainless when your goal is to not penetrate all the way thru.

The 1/4" thick aluminum lap joint showed excellent penetration. The weld hit the root and then some.

With aluminum TIG, unless you are using an argon/helium mix, penetration is a challenge on a 1/4" lap joint.

The laser weld was smaller overall but penetration and weld nugget cross section were awesome.

As handheld laser welders improve, there will be more and more applications where laser will replace TIG.