Learning How to TIG Weld Carbon Steel:

Do these 10 things Right and you Won't go Wrong

Click on topic to jump directly to it:

- Right metal prep ..Make sure metal is clean enough

- Right type and size tungsten

- Right Tungsten prep

- Right cup setup

- Right Gas flow

- Right Filler rod

- Right Polarity

- Right Amperage

- Right Arc length

- Right torch angle

When you are learning How to TIG weld Carbon Steel, If you do these 10 things right, it’s hard to go wrong.

Watch more videos on TIG welding carbon steel at the weldmonger store blog

1. Right metal prep ..Make sure metal is clean enough

- HOME

- TIG WELDING

- Learning How to Tig Weld Carbon Steel

Some carbon steels like cold rolled steel or DOM tubing might be clean enough to tig weld without using an abrasive.

A simple wipe down with a solvent like acetone or alcohol might be all you need.

Other carbon steels like hot rolled sheet, angle, plate, or square tubing has a mill scale coating that needs to be ground down to clean bright metal using an abrasive like a flap disc.

So how clean is clean enough? You can’t go wrong cleaning it down to clean bright metal. That means completely removing any coating and not simply polishing it with a wire brush.

Oxides in mill scale mix with the tig puddle and make it sluggish and that takes all the fun out of tig welding.

2, Right type and size tungsten

The right type of tungsten for tig welding carbon steel is largely a matter of preference but any one of the types of tungsten listed directly below will work just fine for most applications as long as they are sharpened the right way:

** to make things simple, I mostly use 2% lanthanated as single all purpose tungsten for both DC and AC tig welding.

The size or diameter of the tungsten depends on the amperage range for the type work you do. A 3/32” tungsten is a great choice for most people starting out.

A 3/32” tungsten of any type listed above will handle anything from razor blades to 3/8” carbon steel.

3. Right Tungsten Prep

Tungsten sharpeners like the CK turbo sharp, Diamond Ground Piranha, or the Sharpie are super nice but not a necessity....Especially when you are first learning how to tig weld carbon steel.

A bench grinder, hand held angle grinder, belt sander, or even a drill doctor will all sharpen tungsten satisfactorily provided you use a smooth enough wheel or belt and get your grinding marks going lengthwise.

If you get a tip that looks like this, you will be fine.

It does help to use the right diameter tungsten for the job but there is a lot of overlap when it comes to amperage ranges for a given tungsten diameter.

A small diameter tungsten like a 1/16” or even a .040” will generally provide better arc starts at low amperage but it also depends on the machine you are using. If you need to weld something really thin like razor blades with a 3/32” or 1/8” tungsten, you can get better low amp arc starts by using a longer needle point taper.

Conversely, for welding at higher amps, less taper will hold up better at higher amps.

4. Right cup setup

If you are still using the standard TIG cups and hardware that came with your machine or TIG torch, I can just about guarantee you will get better results if you upgrade to a weldmonger® stubby gas lens kit.

The standard cups that come with most tig torches and machines are ok but won’t get you the best results possible.

Those cups are what I learned with and I welded lots of pipe on nuclear plants using standard collet body cups.

But when I transitioned into Aerospace welding, my eyes were opened to how much better gas lens cups work on not only carbon steel, but almost all other metals.

Gas lens setups let you extend the tungsten further while still providing better gas shielding of the puddle and surrounding area.

That translates into more comfort because I don’t have to cock my neck sideways to see the puddle and tip of my tungsten.

It also provides a bit more leeway when it comes to keeping the hot tip of the filler rod in the argon shielded area.

A longer stick out is also handy when reaching into tight angle joints.

5. Right Gas flow

What is the right gas flow for tig welding carbon steel?

If you search google most sources say 15-20 CFH.

I think that’s a dumb statement because in my experience, it depends mostly on the cup size being used.

15-20CFH would be too much for a #4 cup and not enough for a #16 cup.

I think 2-3 CFH per cup size is a better answer.

So for a #10 cup 20-30 CFH will be about right and for a #5 cup would need 10-15 CFH

6. Right Filler rod

TIG welding filler metal is in stock at Weldmonger.com

For carbon steels ER70S-2 and ER70S-6 are the two main filler rods.

The choice is mostly a matter of personal preference but for open root applications or full penetration sheet metal butt joints, ER70S-6 seems to flow better.

Size of the filler rod is also personal preference but there are a few guidelines or rules of thumb that can help out.

One rule of thumb is this: For sheet metal 1/16” and thinner, avoid using a filler metal that is larger in diameter that the thickness of what you are welding. It’s just a general rule of thumb so there are always exceptions.

Once you get up to 1/8” thick, the choice of filler rod diameter depends on things like welding size callout on a drawing, fitment clearance, as well as personal preference.

For example, for an 1/8” thick lap joint .045” , 1/16”, or 3/32” can all work ok.

7. Right Polarity

The right polarity for tig welding Carbon steel is DCEN (electrode negative).

Most modern TIG welding machines have a knob or switch to change back and forth from AC to AC. But it is important to have the tig torch plugged into the correct port in order to be on electrode negative.

There is usually a tig torch icon or a negative (-) indicator to let you know where the tig torch plugs in. If you get this wrong, your tungsten tip will melt away before you can even get a puddle going. I mention this because of numerous emails and forum posts where people have overlooked this detail. And to be honest, I have even done it myself.

Old school tig welding machines might refer to DCEN as “straight polarity.”

8. Right Amperage

How do know how much amperage to use when tig welding carbon steel?

TIG welding is such a versatile welding process because you have a choice to use a foot pedal amperage control, a torch amp control, or a torch button/switch where amperage is on or off.

I prefer a foot pedal amperage control for most of the work I have done and the way that works is I set the amperage on the machine to about 20-30 % more than what I need and control amperage by reading the puddle and making adjustments on the foot pedal.

If I use a tig torch mounted control, I will typically set the amperage on the machine a good bit higher so that I can go from a low amperage all the way to max welding amperage with one single finger stroke.

But with a torch switch , you have to get pretty good at estimating the amperage needed. You can do this on a piece of scrap metal.

There is a pretty good rule of thumb for amperage needed to tig weld carbon steel and it is the one amp per one thousandths rule.

For every thousandths of thickness, one amp is needed so for .125” thick carbon steel 125 amps will get you in the ball park.

This rule works ok up until 125 thousandths but as metal gets thicker you need less amperage per thousandths. In my experience, 180 amps will easily weld a 1/4” thick carbon steel lap or tee joint.

To further illustrate this point , Imagine needing 500 amps to weld 1/2” 0.500” thick steel.

9. Right Arc length

What is the right arc length for tig welding carbon steel.

Here is the best rule of thumb I know for this:

Arc length should be equal or slightly less than the electrode diameter.

Easy to remember and it actually works.

I dont really think about this while I weld but since I edit tig welding videos, I have the benefit os seeing my arc length up close and most of the time it is almost exactly the same as the diameter of my tungsten.

There are always exceptions to this rule...

for example:

- A longer arc sometimes helps when tig welding dirty cast steel

- A tighter arc sometimes helps when tig welding very thin metal

If you hold the arc too tight, you will dip the tungsten more often.

If you hold too long an arc, you will lose the pinpointed heat that TIG is known for.

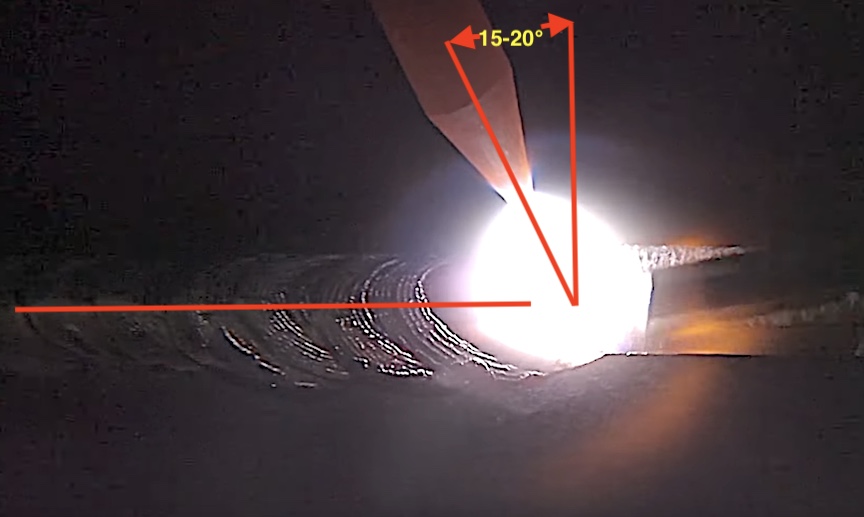

10. Right torch angle

Most Textbooks and technical guides agree that a 10-20 degree torch angle is best.

aiming for a 10-20 degree torch angle is good practice when you are learning but when you starting making parts or welding in the field, Each situation is different so torch angle is what it is to get things done.

Fortunately, torch angle is pretty forgiving provided arc length is good.

Easy Simple Settings for Beginners

- HOME

- TIG WELDING

- Learning How to Tig Weld Carbon Steel

I have created a No BS TIG workbook for you to help you learn to TIG weld...and its free

Download your Free TIG workbook here

Download your Free TIG workbook here