Tig Welding Aluminum Lap joints with the Lincoln Tig 175

In this video, I am using a simple Tig Welder...

A Lincoln Tig 175 square-wave.

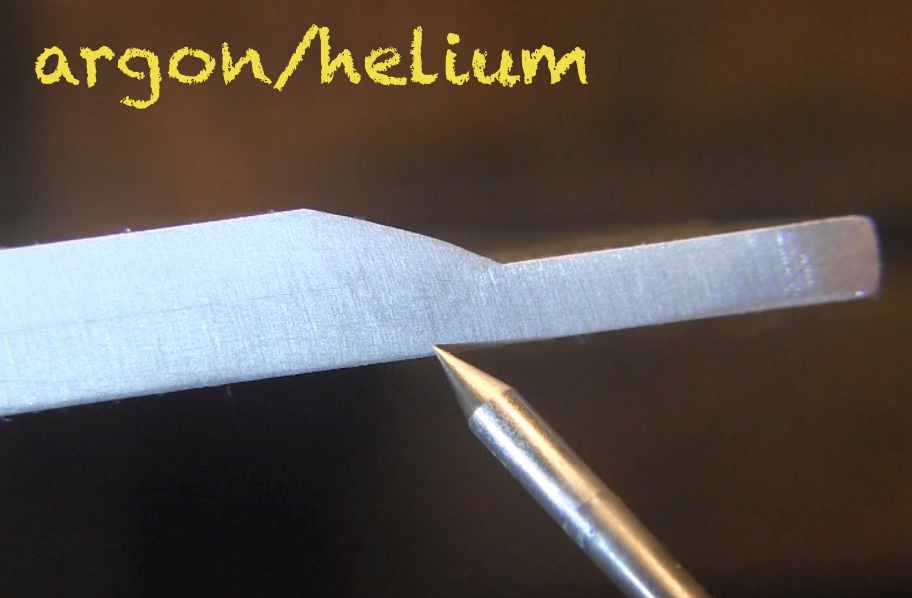

This is part 2 of Tig welding aluminum laps with ar/he mix

check out the weldmonger store

But even with a basic tig welder, when you add helium, all of a sudden, it welds thick aluminum better.

Does helium make that much difference?

Is it worth the expense?

I saw a quote the other day that describes this video pretty well and it goes like this...

"One test beats a thousand expert opinions"

in case you have not seen part 1 yet, here it is

or click here to watch part 1 along with the full article

Why the Lincoln TIG 175?

I decided to use the simplest and most basic tig welder that I have to show what can be done with helium...

without all the bells and whistles that come on fancy tig inverters.

The Lincoln Tig 175 is a transformer style power source and has a AC frequency of 60hz. There is no AC balance or AC frequency adjustment.

And while its perfectly capable of welding 11 ga aluminum without adding helium, I limited amperage to 100 amps just to show the difference between pure argon, and a argon/helium mix.

Testing the welds

The quickest, cheapest, and easiest way to test an aluminum lap joint like this is the Macro etch test.

Macro just means low magnification ( like around 10x) so a fine polish is not necessary just to reveal the weld nugget profile.

Fortunately, there are several household products that will do the job for etching the weld area.

Etching is sort of a controlled corrosion.

Etching aluminum using an alkaline solution removes a surface layer of smeared metal and allows a person to distinguish between weld metal and base material.

I used Easy Off oven cleaner for this video. I just sprayed a small amount on a Qtip and swabbed the weld for a few minutes and then wiped clean with a wet paper towel.

And now, the Results of the Macro etch test...

The lap joint welded at 100 amps using pure argon didnt penetrate near as much as the lap joint welded at 100 amps using argon/helium mix.

...and there was a bit of porosity too.

The point is, that if you are limited on amperage...

Like say, you have a miller diversion 180, or a Thermal ARc 186, or even a Dynasty 200, Sometimes, helium can get you over the hump without needed a bigger welding machine.

And even if you have plenty of amperage, helium mixed with argon provides a cleaner puddle.

If you cant get helium, there is another alternative called Stargon AL from praxair.

Stargon AL is not quite as hot as adding helium but almost and its more affordable.