Metalworking Hand Tools Organizer

This video is about organizing your metalworking hand tools, plasma cutting, some old school stick welding, and an explanation of the back step welding technique that helps avoid distortion.

A while back I posted a video showing a dead simple way to make a do-it-yourself portable bandsaw stand.

A reader emailed me some pics of one he had built and I thought it was about the simplest and easiest to build plan I had ever seen for a portaband stand so I thought I would send it out to everyone.

Later , forum member Kiwimike on my welding forum even made a portable bandsaw stand using a cheap harbor freight portable bandsaw.

I got quite a few comments telling me there was a very well made portaband stand available at a website called swagoffroad.com...

so I checked it out.

I wound up contacting Troy at Swagoffroad.com about doing a video on some of his stuff ....and that brings me to the main topic of this video.

Swag Off Road mostly focuses on aftermarket accessories for off road enthusiasts but they also offer some very cool and innovative welding tools.

Here are the main three that caught my eye:

The clutter catcher

The Portable Bandsaw Stand from SWAG offroad

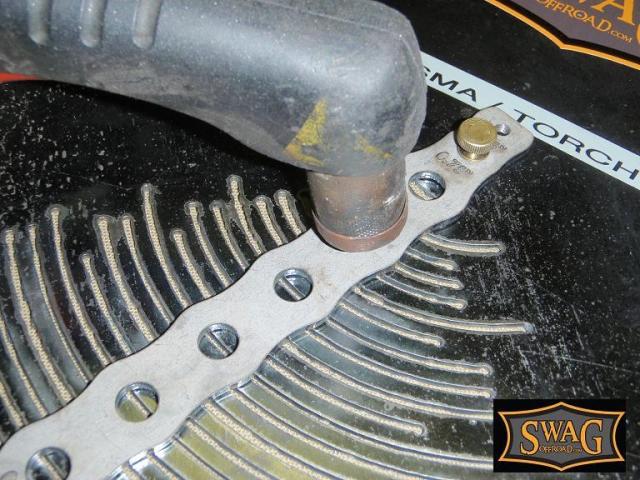

Plasma Circle Cutter

I am not the neatest guy in the world. In fact, I do some of my best work in the middle of a mess. Its not intentional, It just happens. I have to stop work sometimes just to put some things away because it gets out of hand.

Who better than a messy guy like me to show how well the "Clutter Catcher" works. So I figured I would make a video like the one at SWAG but with a few welding tips and tricks added in.

I got out 2 angle grinders, 1 air motor drill, 2 air grinders, many vise grips type clamps, a combination square, 3 sharpies, wire brush, grinding wheels, mig pliers, big freakin hammer, adjustable wrench, 2 third hand tools, and several other metalworking tools.

When its all laid out on the table , it looks like there is no way it will all fit in the Clutter Catcher....

But it does.

This thing is Awesome.

As I continued to work showing some outside corner joint welding on 16ga hot rolled steel, I found that I could find my tools fast... and get to them quickly and easily.

I just clamped my clutter catcher on the end of my Stronghand welding table with clamps until I decide where to mount it permanently.

Plasma cutting sheet metal

A plasma cutter is a very useful tool.

It cant take the place of a sheet metal shear but it can come pretty close.

For cutting sheet metal with a plasma cutter, less than 40 amps is needed and at that amperage, the torch tip can be rested directly on the metal being cut which allows for dragging the torch against a straight edge.

The idea is simple. Figure out the dimension between the center of the torch and the edge, and clamp a straight edge that distance off where the cut should be made.

Its easy once you figure out the optimum amperage setting, travel speed, etc.

Plasma cuts are cleaner than oxyfuel cuts on sheet metal and it doesnt even matter what kind of metal you are cutting.

Of course, the dross needs to be ground off before welding, but that only takes a few minutes.

QuikStrike Welding rods 6013 1/16" for sheet metal

Did you know that you can get 1/16" stick welding rods that will let you weld thin sheet metal with a stick welder?

its true.

1/16" is pretty small. The rods feel like tiny sparklers.

but they run good.

these little 6013 welding rods run good downhill because the puddle is so small.

Normally, a 6013 welding rod is too slaggy to run downhill...the slag runs ahead of the puddle and causes all kinds of problems.

Keep in mind, 1/16" 6013 rods make a puddle that is only about 1/8" wide.

So if you have some thin stuff to weld and dont have a light duty mig with .023" bare wire and gas shielding, your stick welder might just do the job as long as you have some tiny little 1/16" rods.

The backstep welding technique

What is the backstep welding technique?

basically, its welding in a certain direction, but the weld progression is in the other direction.

It limits distortion.

The backstep welding technique is best shown in a video so watch that sucker.

A metalworking Hand tools organizer designed for welders

If you are looking for a holder for your metalworking hand tools, I cant think of a better tool than the "Clutter Catcher" from Swagoffroad.com.