MIG WELDING CARBON STEEL .063" WALL SQUARE TUBE DOWNHILL

- HOME

- WELDER SETTINGS

- Mig Welder Settings

- Mig Welding Square Tubing

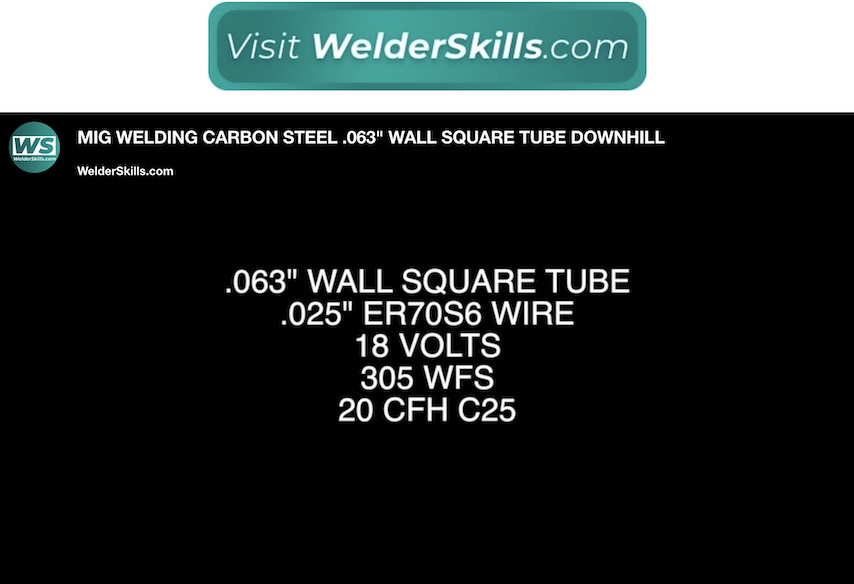

METAL TYPE = CARBON STEEL SQUARE TUBE

THICKNESS = .063"

WELD TYPE = GROOVE

JOINT TYPE =BUTT

POSITION = 3G DOWNHILL

VOLTS = 18 volts

WIRE SPEED = 305 IPM

WIRE SIZE = .025"

AMPS =

POLARITY = DCEP

GAS FLOW = 20-25 CFH C25 GAS

CTWD = 3/8”-1/2"

TUNGSTEN =

FILLER METAL = ER70S6 .025"

ADDITIONAL SETTINGS =

TIPS:

A relatively short stickout aka contact to work distance CTWD of 3/8” to 1/2" makes a big difference.

The technique shown is a very slight side to side motion while keeping the arc on the front edge of the puddle