Mig Welding Downhill

Part2

As expected, Part 1 of Mig welding downhill generated as many questions as it did answers.

Folks commented and asked lots of questions so I am following up with this Part 2 video to keep the conversation going.

Not everyone has the time to test mig welds all day.

And to be honest, I need to get back to some paying work soon.

But today, I am doing exactly what I want to do...

I am playing mad scientist again and welding, slicing, polishing, and etching.

click here for part1

Does cleaning Mill Scale make a real difference on Mig welding downhill?

In part one, I welded a lap joint using hot rolled steel without cleaning the mill scale. 20.5 volts and 303 ipm of .035" er70s6 wire.

The results surprised even me... and I have cut and examined a whole bunch of welds.

I really expected this weld to be a lot better than the one welded using .024" (.6mm) wire.

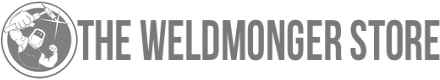

But instead this weld had serious lack of fusion in the root and extending over half the thickness.

Keeping the settings the same but cleaning off the mill scale resulted in a better weld nugget profile. But still questionable.

I say questionable because their was just no real depth of fusion.

While I am sure there was some fusion going on, the weld looked more like a braze or soldered joint.

You dont want to see straight lines when you cross section and examine a fillet weld.

so then I wondered if lower settings and a slower travel speed would help

It might seem odd, but after I saw the results of the 1st lap joint at 20.5 volts compared to one done slower but colder, I couldnt help but wonder if slowing the travel speed just a bit using lower settings would actually improve the penetration.

It did.

What if I did 2 quick Downhill passes?

The thought occurred to me...

If the puddle is chasing me, and fast travel speed is preventing penetration, then what if I weld 2 smaller passes?

will that help?

I tried to really point that wire into the root on the first pass.

and after about 30 seconds of cooling time, I came back with the second pass....trying all the while to keep the arc on the leading edge of the puddle.

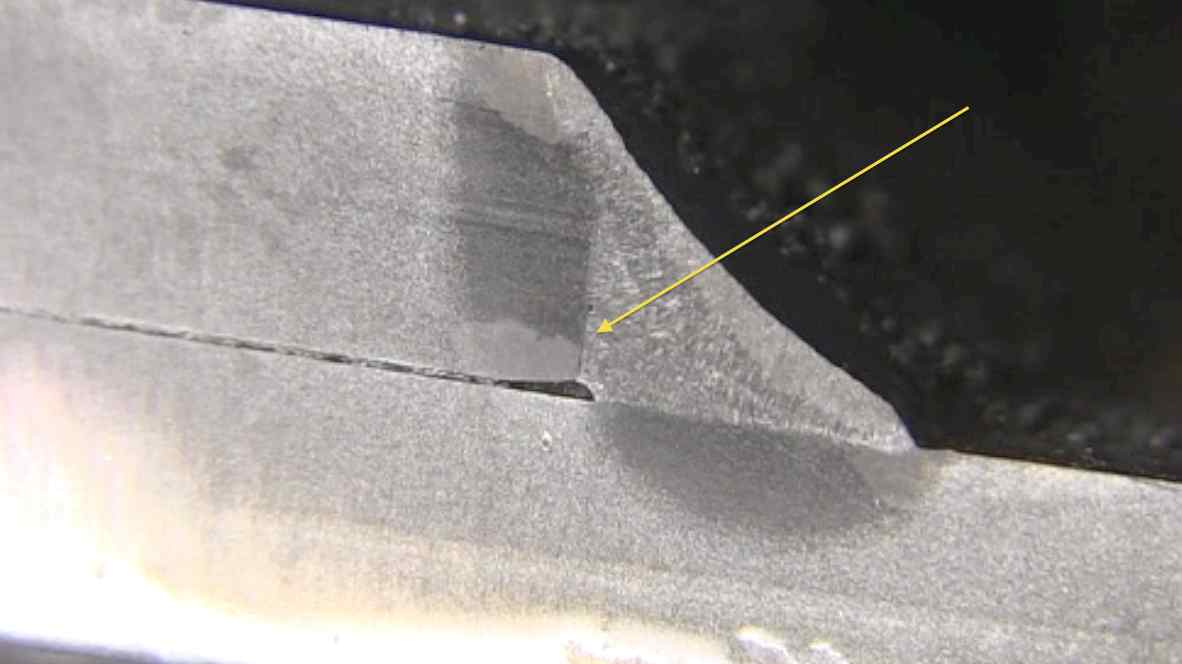

The results of the 2 pass downhill weld were less than amazing.

there was a pretty distinct fusion line, but a straight line is not something you want to see. there was very little depth of fusion.

This method has potential, but does not seem robust.

I would like to see some more depth of fusion to feel good about it.

Lets compare some downhill mig welding to uphill

Welding on mill scale again and not cleaning at all.

and Lowering the settings to 18.5 volts and 211 ipm wire speed revealed this...

Thats a nice nugget profile with plenty of depth of fusion.

lets try one more and clean the metal and lower the wire speed

18.5 volts and 190 ipm using .035" wire and on clean metal.

all mill scale removed.

Mig welding Downhill is definitely easier and faster, but...

When penetration is the main thing uphill might be the best choice

This objective of this video is not to say all downhill mig is bad.

But rather just to show a few things like...

- the need for testing to establish good procedures.

- the need to utilize a welding technique that adequately keeps the arc at the leading edge of the puddle

- the need to remove heavy mill scale prior to welding downhill

- even lower settings get more penetration going uphill vs downhill and mill scale does not affect the penetration much like it does with downhill mig

Again, my rule of thumb is to weld uphill on 1/4" (6.5mm) and thicker

See more videos on MIG