MIG Welding Pipe in 5G

want to see more pipe welding videos?

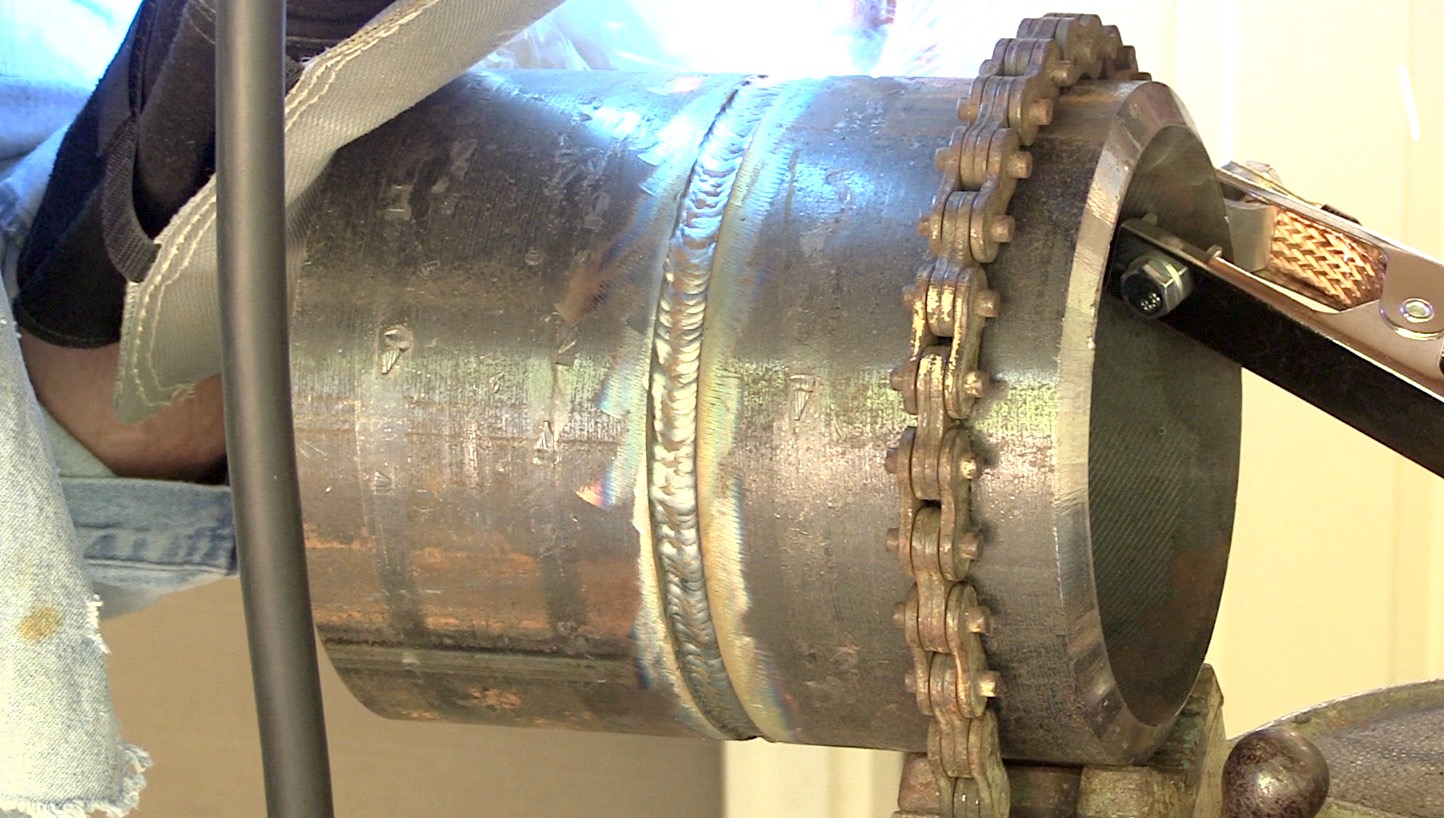

This page is about MIG welding pipe ...6 inch schedule 80 pipe using short circuit mig and an Esab Rebel 205 welder.

5g position downhill root and uphill fill and cap.

5g is where the axis of the pipe runs horizontal.

This is similar to a 3g plate video I did a while back.

A 3g Plate is a bit easier than 5g pipe, mostly due to the body positioning required but also because you start off in flat, transition to vertical, then to overhead.

For the 3g plate, I set a 5/32” gap for the root and so my settings were quite a bit different that for the pipe, but for the fill and cap, the settings were pretty close to what were used on the 3g plate.

I think welding plate is good practice for pipe as long as the bevel angle and thickness is the same.

In fact, you can pretty much use the settings you dialed in for plate on pipe ..provided you figure in some settings that work on both vertical and overhead.

I worked in a fab shop years ago, and I was sent to the test shop to certify on a 5g pipe mig all the way.

I had already passed several tests so the pressure was off as far as getting the job…

so the test shop was more like a training situation at that point.

The instructor had me put 2 tack welds on a 8 inch pipe with tig, and for some reason instructed me weld the root downhill from tack to tack 12 o'clock to 6 o’clock …and then without even stopping, come back uphill to 12 o’clock.

It seemed like a strange way to weld pipe, but he was the instructor so I did it.

I was having some low back issues at the time and staying leaned over that long was killing me. It seemed to take forever to make that downhill/uphill run.

After a few practice pipes, The instructor said I was ready for the test…

So I tacked up a pipe and feathered the tack welds and put it in 5g position.

When he came to inspect the fit up, I asked if I needed to weld the test the same way he instructed me before.

He says “Nah man, I was just messing with you on that!” and then he just walked the hell away.

Root Pass settings

Root pass on this 5g pipe was welded at 18 volts and 210 ipm wire speed

MIG Welding Pipe-2nd pass

For the 2nd pass, I set the voltage to 19.5 and wire speed to 200.

This setting created a bit of spatter but did accomplish the main goal.

And that is being about 1/16" below flush so that the cover pass would go in nice without excessive reinforcement.

Mig Welding Pipe- Cover pass

For the cover pass, I reduced both voltage and wire speed to 18 volts and 180 ipm.

I learned the hard way that I needed to stop and let cool for a while in between the fill pass and cover pass