The One Page Aluminum TIG Welding Plan

The One-Page Aluminum TIG Plan- A Back to Basics Reference

Know What Aluminum You’re Welding

- Some aluminum is not recommended for arc welding (2 main ones are 2034 and 7075)

- Aluminum conducts heat fast

- No color change before melting

- Oxide layer melts much hotter than base metal

Mindset rule:

Read the puddle and add rod to puddle not the arc.

Machine Setup (Keep It Simple)

Simple TIG settings for both steel and aluminum using a PrimeWeld TIG225

In my opinion, the primeweld 225 is one of the best choices in affordable tig welders.

The problem with most other really affordable tig welders is usually a really cheap foot pedal and TIG torch. Primeweld went to extra expense to include a genuine CK17 torch with superflex hose along with a very smooth SSC style foot pedal.

A high quality CK dinse adapter is also included so that you can easily swap out a tig torch or cable when the time comes.

Primeweld also has a responsive primeweld equipment users group on facebook and also has demonstrated great customer support

Watch some more primeweld videos and you will see what I mean.

AC balance setting tips

After watching the video below, you will have a good understanding of the AC Balance setting on any tig welding machine.

Learn more about this affordable tig welder with bonus kit at weldmonger.com

AC Frequency settings

Need to learn how to set AC frequency for different applications?

watch the video below

- Process Setting: TIG

- Polarity: AC (make sure the tig torch is plugged in to the correct dinse port)

- Shielding gas: 100% Argon

- AC balance: Enough cleaning to get a shiny clean puddle

- AC frequency: Higher for tighter control, lower for wider arc and more heat input on thick aluminum.

Rule of thumb:

Know your Settings but More knobs don’t always mean better welds.

AC frequency is a "nice to have" feature but sound welding technique makes more difference than AC freq.

Learn more about this affordable tig welder with bonus kit at weldmonger.com

Clean the Metal

- Degrease with acetone or alcohol

- Dedicated stainless steel wire brush

- Light brushing to remove oxide

- No shared grinding wheels or brushes

- Brand new clean aluminum often only needs a wipe down before welding

Rule of thumb:

Dirty aluminum welds dirty — every time.

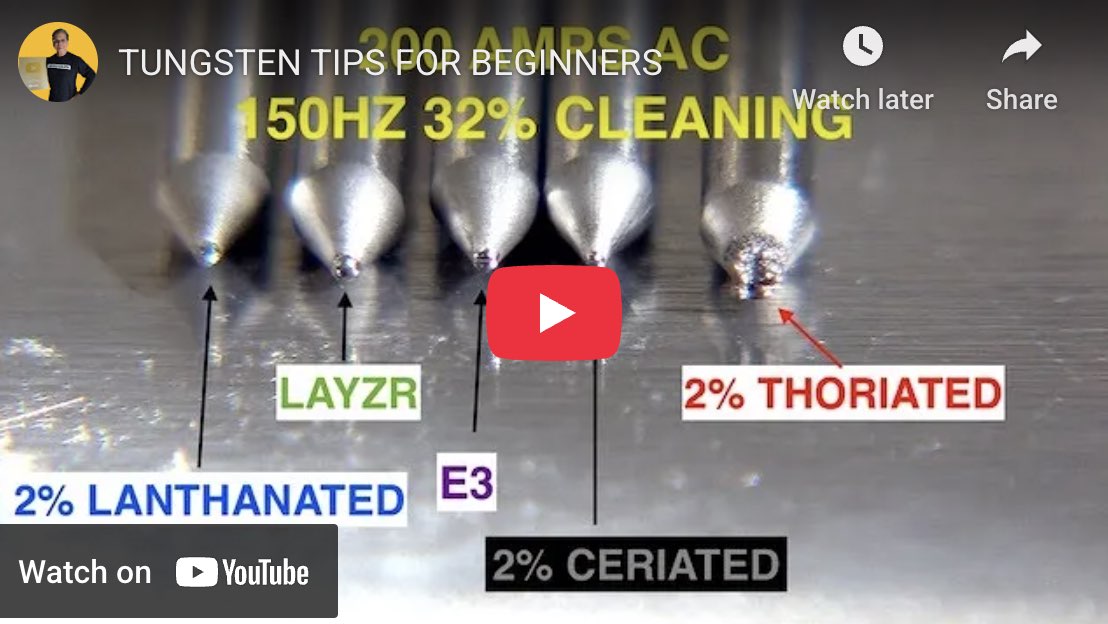

Tungsten Selection & Prep

- Use 2% lanthanated or multi-mix tungsten like E3 or LaYZr

- Don't use pure tungsten

- Choose size based on amperage

- Small balled or truncated tip

- Clean tungsten only

Rules of thumb:

- Bigger tungsten for thicker aluminum

- Giant ball on tip = arc wander

- Dirty tungsten = frustration

Cup, Gas Lens & Gas Flow

- Use size 4 thru 8 cups - A Gas lens helps especially with a longer stick out.

- Moderate gas flow (avoid turbulence) 2-3 CFH per cup size

- Adequate stickout without losing coverage

Rule of thumb:

If the aluminum metal is clean and the aluminum puddle still looks dirty, think gas first. then ac balance settings.

Amperage & Heat Control

- Starting point: ~1 amp per thousandth up to 125 amps for up to .125" for corner joints and slightly more for tee joints and lap joints

- Aluminum often needs more initial amperage and less amperage as the metal heats up

- Set machine amps higher and Use the foot pedal to manage heat

- Back off amperage as needed as heat builds

Rules of thumb:

- Start hot, then back off

- Pedal is a heat control tool

- Mindset=Puddle melts the rod…not the arc

Arc Length & Torch Angle

- Keep a short arc equal to or less than electrode diameter.

- Slight push angle...avoid steep torch angle

- Steady torch movement

Rules of thumb:

Tungsten diameter = 3/32” 2% lanthanated is good up to 200 amps

Above 200 amps might need a 1/8" tungsten

Arc length = same as tungsten diameter

Torch angle= 15 degrees but is pretty forgiving if arc length is right

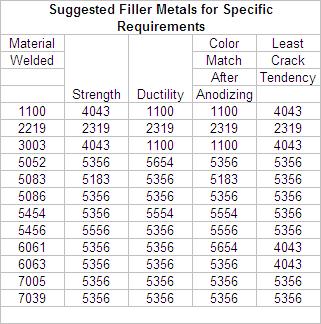

Filler Rod Selection & Technique

TIG welding filler metal is in stock at Weldmonger.com

- Common fillers: 4043 (smoother) or 5356 (stronger)

- Use smaller diameter for thinner metal

- Keep hot tip of filler inside shielding gas

- Add filler early

Rules of thumb:

- Filler rod diameter not bigger than thickness welded (usually).

- Larger diameter filler rod is easier to feed but chills puddle more

Practice Drills (Do These First)

Practice stacking and padding beads on plate before doing weld joints.

Troubleshooting Quick Check for TIG welding aluminum

- Black soot → gas coverage or contamination of tungsten or base metal

- Gray/dull welds → not enough ac balance cleaning, metal not clean, not enough argon shielding

- Cracking → not enough filler or wrong metal

- Tungsten melting → too much cleaning action (EP) on ac balance or tig torch plugged in to wrong port

- Arc wander → contaminated tungsten, balled tip, tungsten too large, split tungsten .

Fix fundamentals before chasing settings.

Final Reality Check

Aluminum TIG welding isn’t about magic settings.

It’s about:

- Clean metal

- Stable arc

- Good gas coverage

- Heat control

- Practice with intention. Think improving each bead vs just reps.

- Get those right, and aluminum stops being frustrating and starts being fun.