Oxy-Fuel Cutting with Propylene

Faster Cuts? Cheaper overall cost? or sales talk

"Propylene is not hotter...or is it??? "

Have you ever thought of converting your oxy-fuel cutting torch from acetylene to propylene?

It can be a really good move for some people. But like anything else, it has its advantages and disadvantages.

In the welding forums it seems like the topic of cutting with propylene vs acetylene really gets the hackles up.

Some people insist that acetylene is better and that the benefits of oxy-fuel cutting with propylene is just sales talk.

I have seen a few shops change over and tout the benefits...but its not for everyone.

Propylene vs Acetylene

advantages

* more stable and safer than acetylene and no 15 psi limit on working pressures

* no soot

* more btu's of heat for heating large parts and thick metal

* cuts metal quickly and with a very long tip to work distance

* acetylene prices are rising much faster than propylene

* better heat transer properties than acetylene

* no withdrawal rate limitations

disadvantages

* cant gas weld with it...too much pressure and too much flow rate to weld metal with any quality

* requires different tips and T grade hose

* slight learning curve on lighting and setting the torch

If you are still interested, here are some factoids and pointers:

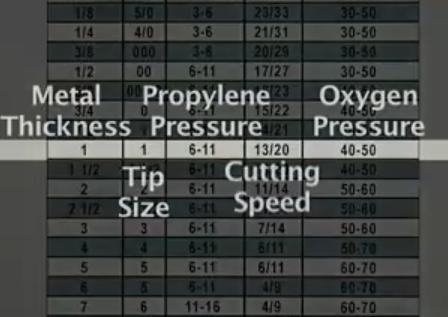

For converting to propane or propylene type fuel gas, use the manufacturer's tip chart to select the right cutting or heating tip and set the fuel and oxygen gauges to what the tip chart dictates. The pressure settings might be very different from what you are accustomed to with acetylene.

Different way to light and set the torch

Most manufacturers instructions for propylene cutting equipment recommend turning both oxygen and fuel gas on before lighting the torch...something you should not do with acetylene. Either way, check valves are a must.

Once the torch is lit, increase gas and oxygen alternately until tip cones reach about a quarter of an inch….this is important , you cant adjust the gases one at a time and be don like you did with acetylene or the flame will go out. . You have to adjust each gas alternately and gradually until you achieve the right size flame.

Next add more oxygen until you hear it whistle.

You know you have it right when you get the quarter inch cones, and a three inch star pattern on the metal when you hold the tip close like you are getting ready to pierce.

In the video, Did you notice how quickly the metal turned red hot? Even though the flame temperature of a propylene oxygen flame is less than that of a acetylene oxygen flame, there is more heat available.

How can that be? You ask….

Its because of the BTU’s. Being able to adjust the fuel gas pressure way higher than 15.

Not being limited on withdrawal rate lets you have more heat.

Let me explain. Acetylene is actually stored under pressure as liquid acetone in the cylinder filled with a concrete like porous material.

That’s the reason for all the warnings about laying them on their side...because liquid acetone can get in your regulators and hoses and screw them up.

That liquid acetone has acetylene gas compressed into it like a carbonated soft drink.

The gas will only come out so fast. This limitation is called “withdrawal rate”. And it’s the reason you cant run a big rosebud heating tip off a small bottle of acetylene. The liquid acetone just can release acetylene gas quickly enough.

In fact it is very surprising to see just how large an acetylene tank it takes to safely operate a rosebud multi-flame heating tip.

Propylene does not have this limitation. You can crank up the flow really high and drive heat into the metal without worrying about sucking liquid acetone thru the lines.

So even thought the flame temperature is a little lower (5198 f for oxy-propylene vs about 6000f for oxy-acetylene) The total heat is greater.

Did you catch the statement about how quickly you can start a cut? The narrator says “you will be able to start the cut on a square edge of cold plate in less than 2 seconds.

Now anyone who has cut with an oxy-acetylene cutting torch knows it takes a little longer than that to start a cut. An oxy-propylene torch is just quicker.

Some other benefits are being able to use really large rosebud heating tips without manifolding 2 cylinders together like you sometimes have to do with acetylene.

Heating up a 2 inch thick bumper from a jet tug or forklift, is where propylene really shines.

It cuts quicker, heats faster, and is more stable and safer than acetylene. So whats the catch?

Well, it does requires different cutting and heating tips and gas welding is not an option.

other than that, its a good choice.

If you have the opportunity to attend a welding show at your local welding supply or even the big shows like the AWS welding expo, you can see many demonstrations of cutting with propylene. The most common demonstration seems to be a contest to see who can cut a 2 or 3 inch piece of round stock in the quickest time.

Its surprising to see how quickly you can make the cut using propylene.

exit oxy-fuel cutting with propylene see more on cutting torch safety