Scratch Start TIG Tips and Techniques

Weldmonger Stubby Gas Lens kit for 17,18,26 style TIG Torches

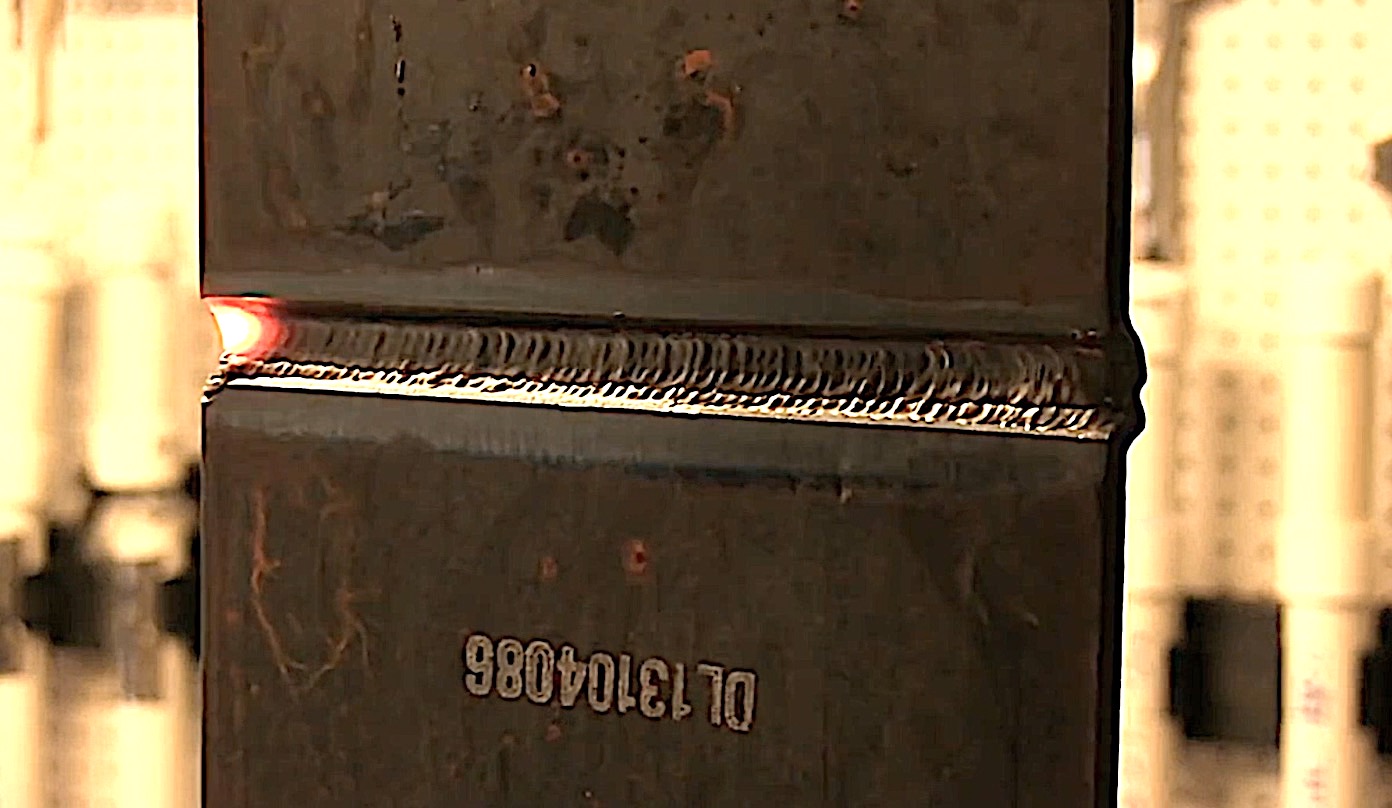

In this video, I used a simple scratch start setup to weld an open root on a practice plate.

A lot of jobs still test using scratch start tig rigs because of the portability and simple equipment used on job sites.

I used a miller thunderbolt stick welder that I got off craigslist and hooked up an air cooled 17 style tig torch with a stubby gas lens.

The amperage readout on stick welding machines like this thunderbolt are not that accurate but you often run into situations on job sites and test shops where the welding machine amperage is crude.

In fact, Its a good idea to practice estimating amperage on different machines before going to take a weld test.

FYI, I used a multimeter to make sure the amperage I stated in the video is close.

ROOT Pass Technique and settings

6g test in your future? …Get dialed in on plate first

If you have never welded pipe, it makes sense to weld a few plates first.

The fit up for a pipe test is usually around 1/8” gap with zero to 1/16” land (usually no land)

With 30-37.5 degree bevels.

The

plate I used came from triangle engineering and was 3/8” thick with

37.5 degree bevels and I gapped it 1/8” using a 1/8” filler rod.

Starting the arc with scratch start tig

There is a trick for starting the arc with a scratch start dry rig that prevents crapping up the tip of the tungsten.

Simply flick the filler rod where it briefly makes contact with the tungsten and plate or pipe as you swipe it by.

This will usually start the arc without compromising the sharp tip of your tungsten.

Technique for root pass

There are several techniques that work for an open root on plate and pipe.

Laywire

technique is just one of many but when I use the lay wire technique , I

usually freehand and use a forward and back motion instead of side to

side.

Reason?

I seems to push the root in more and results in some reinforcement on the back side.

You might notice that I used a tig finger here because I like to be able to focus on the weld and not my burning fingers.

At 100-120 amps, the root went it pretty nicely.

For

the hot pass, sometimes I increase the amperage a bit but there are

times when I weld the hot pass at the same amperage as the root pass.

Walking the cup works well on the hot pass too.

I used a #8 stubby gas lens cup but the size cup that works the best depends on the bevel angle and fit.

Once you get enough practice on plates, use the same settings for pipe.

Good luck welder,

Jody