Silicon Bronze TIG Brazing

more videos on tig brazing

Before we dive into this weeks Silicon Bronze project, lets make sure we all understand the difference between brazing and welding.

Brazing is defined as a joining process in which two or more metal items are joined together by melting and flowing a filler metal into the joint, the filler metal having a lower melting point than the adjoining metal but above 840F...so the base metal never reaches its melting point.

Soldering is much the same as Brazing except that the temperatures are lower (below 840f).

Welding differs from brazing or soldering in that the base metal is actually melted.

TIG Brazing is very useful for applications like the one pictured below where a metal is worn very thin.

Because of the large difference in melting points between carbon steel and silicon bronze filler metal, very thin base metal can be overlayed without melting away the base metal.

silicon bronze overlay of worn area

silicon bronze tig brazed steel cubes

Brazing depends on a clean surface free from oxides in order to have a good braze joint.

Brazing and soldering of any kind rely on an oxide free surface so that the filler metal can flow and bond.

In Brazing and soldering with a torch, flux is usually used to scour the surface chemically. (sometimes flux is not needed due to chemical composition of some filler metals and their reaction with the base metal...example sil-Fox or silphos filler used on pure copper)

In tig brazing, argon or helium shielding gas protects the clean bright metal from oxidation.

So it stands to reason if you start with clean metal and maintain an argon shield on the metal, the braze material will flow better.

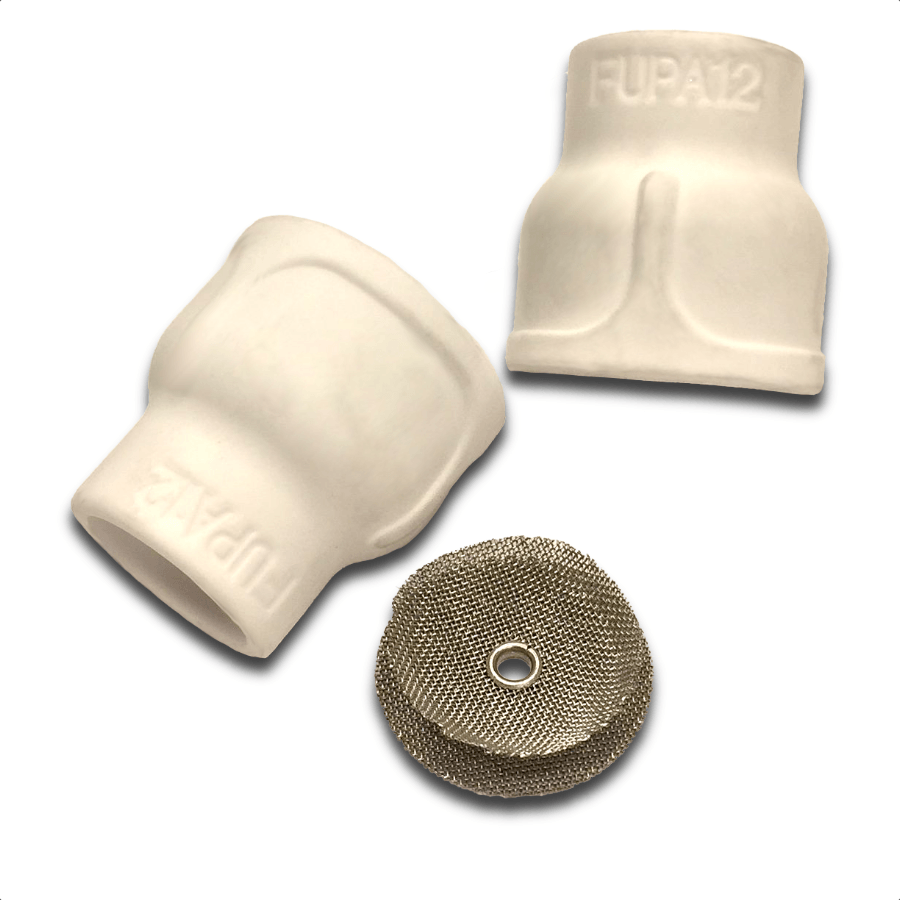

That is why I chose a #12 cup for this project.

The Ceramic 12 furick cup I used provides a much larger argon shielded area than a smaller 7 or 8 gas lens cup and also lets me extend the electrode farther which really helps me film the arc.

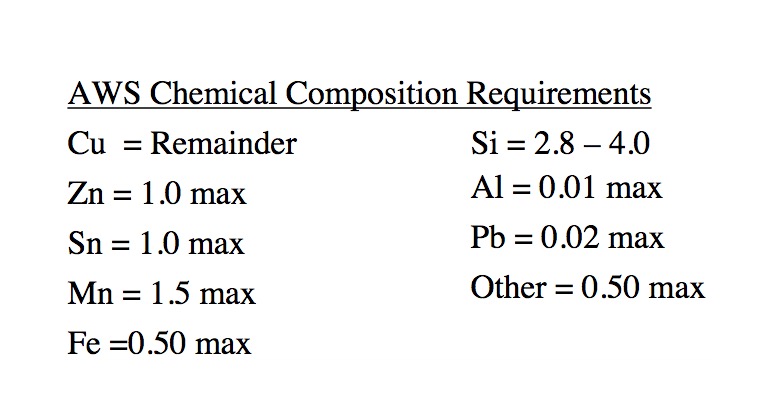

What exactly is Silicon bronze filler metal?

Silicon bronze filler metal is made up of mostly copper with 2.8-4% silicon and and trace amounts of manganese, tin and zinc that lower the melting point to around 1900f.

silicon bronze filler metal was years ago referred to as “Everdur”

...and it can be used to join base metals of steels and cast iron to copper, brass and bronze. May also be used to weld on galvanized steels.

Silicon bronze is excellent for joining plain or galvanized steel sheet

metal as well as other coated steels. It is also used

for surfacing areas that are subjected to corrosion.

including overlaying of steels and cast irons.

Since steels melt at a much higher temperature ( usually 2500F or higher) using Silicon Bronze for joining steel with the TIG process is called TIG brazing and not Welding.

We often casually refer to "TIG brazing" with Silicon Bronze as "TIG welding". But just to be technically correct, I will use the term tig brazing for this article.

Tensile strength of Silicon Bronze is around 50,000psi.

That is comparable to some steels but a tig brazed joint is not always as strong as joint tig welded with er70 tig rod.

The die cube in the video is made from 14 ga hot rolled steel and was cut on a plasma cam cnc table.

After cutting the bending was done using a SWAG off road press brake fitted on a harbor freight press.

tig welder settings using lay wire technique

I found that by using around 1 to 1.5 pulses per second and a 30% pulse time, I could just leave the silicon bronze filler rod in the puddle and since that reduces the chances of oxidizing the hot tip of the rod when dipping it in and out, it seemed like a good plan.

And it worked very well. the pulse settings kept the puddle from overheating and kept oxides to an acceptable level.

overheating can cause hot cracking in addition to lots of oxide formation so its best to keep the interpass temperature to around 150F.

(in layman's terms interpass temperature is the temperature you let the part cool to before welding another pass)

Interpass temperature as defined by ASME Section IX;

interpass temperature: the highest temperature in the weld

joint immediately prior to welding, or in the case of multiple

pass welds, the highest temperature in the section of

the previously deposited weld metal, immediately before

the next pass is started.