Simple Welding Metallurgy for Carbon Steel

...Boiled Down for Welders and welding students

- HOME

- CARBON STEEL

- Simple Welding Metallurgy

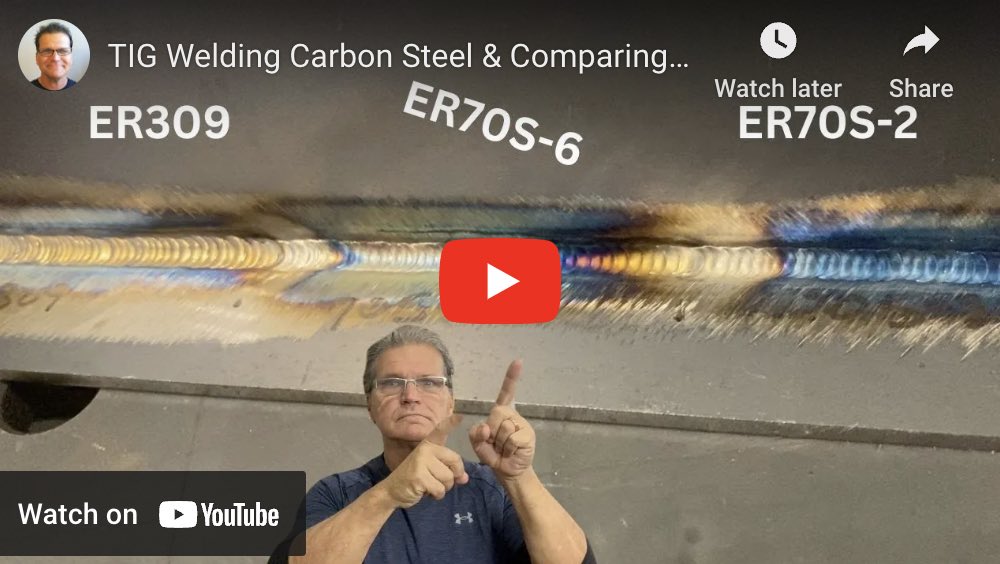

Watch the latest welding videos at Weldmonger.com

Simple Welding Metallurgy as It Applies to Welding Carbon Steels, written in clear, practical language for welders, fabricators, and students:

Understanding What Really Matters in the Weld Zone of Carbon Steels

For most welders, metallurgy might seem like a subject best left to engineers in lab coats. But if you weld carbon steels, you're already dealing with metallurgy—whether you realize it or not.

The key takeaway? The main concern is making a sound weld that doesn't weaken the part or lead to failure in service.

This article breaks down just the essentials every welder should understand to avoid problems like cracking, brittleness, or loss of toughness.

What are the Main Concerns When Welding Carbon Steels?

The main concerns are preserving the strength, ductility, and toughness of the steel in and around the weld. Poor heat control or the wrong process can cause:

- Cracking (especially cold cracking)

- Loss of toughness in the heat-affected zone (HAZ)

- Excessive hardness

Surface Prep Tips for Carbon Steel

No matter what process is used, cleaning mill scale helps.

Clean metal is especially important with TIG welding but removing mill scale prior to welding is never a bad idea.

Mill scale traps moisture and there is hydrogen in moisture.

Why Are Low Hydrogen Processes Specified in Welding Procedures?

The Hydrogen molecule is tiny and can permeate the grains of a steel during welding.

Then upon cooling, the hydrogen molecules try to escape and create lots of internal stress in the metal.

Hydrogen is the enemy when welding medium to high carbon steels and even low carbon steels in certain thicknesses..

If hydrogen gets trapped in the weld or HAZ, it can lead to hydrogen-induced cracking, also called cold cracking. This type of cracking may show up hours or even days after welding.

Low hydrogen processes (like SMAW with E7018 or GMAW with proper shielding gas) are used because:

- They limit moisture and hydrogen from entering the weld.

- They help prevent delayed cracking in hardened zones.

- They’re critical for structural or pressure vessel work where failure is not an option.

- low hydrogen procedures are specified in codes and specifications

🔥 When and Why Is Preheating Needed?

Preheating can be accomplished a number of ways from using a rosebud torch, to electric heat blankets, to induction heating.

It’s used when welding:

- Thick sections of carbon steel

- High carbon or alloy steels

- Steels with poor weldability (high CE or carbon equivalent)

What does preheating do?

- Slows the cooling rate to avoid rapid hardening

- Reduces the risk of hydrogen cracking

- Helps drive off moisture from the base metal

- Promotes softer microstructures in the HAZ

➡️ Example: A36 mild steel 1/2" thick might not need preheat due to low carbon, but a piece of 2" thick 1045 might require a preheat 400°F or more.

How Does Grain Growth Occur—and Why Avoid It?

When carbon steel is heated to welding temperatures—especially in the HAZ—it changes at the microscopic level.

If the temperature gets too high or stays hot too long, the grains in the steel grow too large. This is called grain growth, and it leads to:

- Reduced toughness and impact strength

- More brittle failure modes

- Poor performance in dynamic or cold environments

Fine uniform grains typically have better strength and ductility.

How to avoid excessive grain growth:

- Control your heat input

- Use proper preheat and interpass temperatures

- Avoid excessive amperage or long arc times

- Follow WPS (Welding Procedure Specifications) for base material

- for multipass welds, stringers generally produce less grain growth than weaving