Socket Weld and Walking the cup

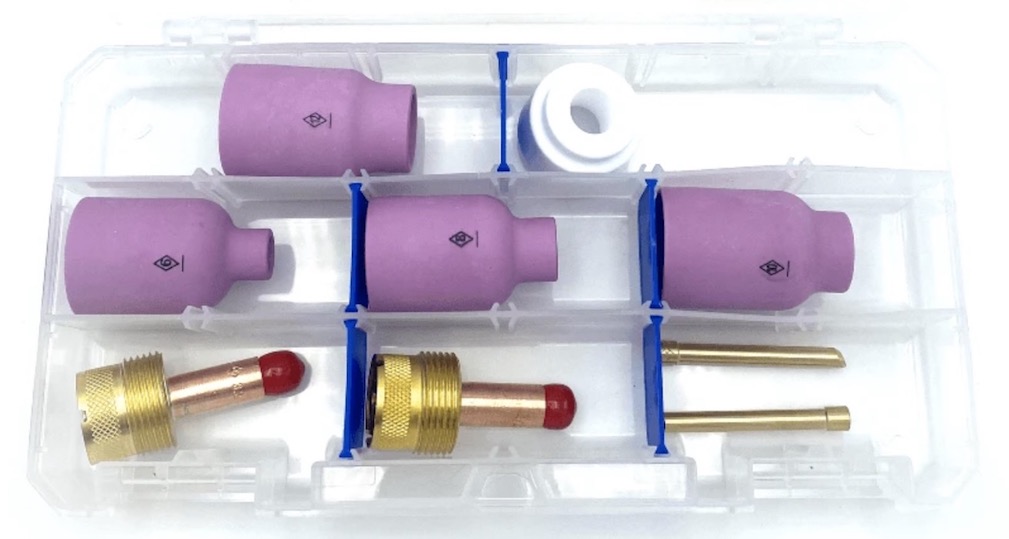

Learn more about the Large Dia Gas Lens Kit on my store at weldmonger.com

I never welded a socket weld until I passed my first pipe welding test.

I think that is how it is for most of us because most schools dont train on socket welds.

A heavy wall socket weld requires several passes

Learn more about this Large Diameter Gas Lens kit at weldmonger.com

My school was geared toward putting you to work in the pipe industry.

that meant passing a 6g welding test according to who was hiring.

The test might have been a tig root stick fill and cap.

Or it just as well could have been a 6010 root with 7018 fill and cap.

If the instructors thought you were ready to pass whatever test was required, they would strongly encourage you to go.

I failed my first 6G test...but I passed the second one.

And that led me to weld a whole bunch of socket welds.

The way most pipe welding codes are written, a 6g pipe test automatically qualifies you to weld socket welds in all positions.

A socket weld is not exactly the same as an open butt pipe weld but the skill set is similar enough for most welders to figure it out pretty quickly.

It doesnt really matter if you walk the cup or freehand on a socket weld but usually on anything 2 inch and bigger, walking the cup will be a great way to go.

But sometimes walking the cup is not feasible.

there is stuff in the way sometimes so it is good to be able to free hand the weld.

that is where a TIG finger comes in.

A TIG finger lets you prop right next to the weld no matter how hot it is.

Walking the cup with ER309 filler rod on a turntable

For TIG welding carbon steel to Stainless steel, ER309 filler rod is a tried and true tig rod.

309 filler is also good for those situations where you need to fix something.

You know its steel but you are not sure the exact alloy.

A good example is modifying a wrench.

The wrench might have Chromium Vanadium stamped on it but maybe that's all the information you have because maybe SnapOn or MAC tools is not forthcoming on what alloy their wrench is made from.

And maybe you need to weld a 4140 handle on that chrome vanadium alloy wrench.

what rod do you use?

ER309 is usually a great choice for situations like that.

ER309 is designed for welding carbon steel to stainless steel but it is great many dissimilar metal welds.