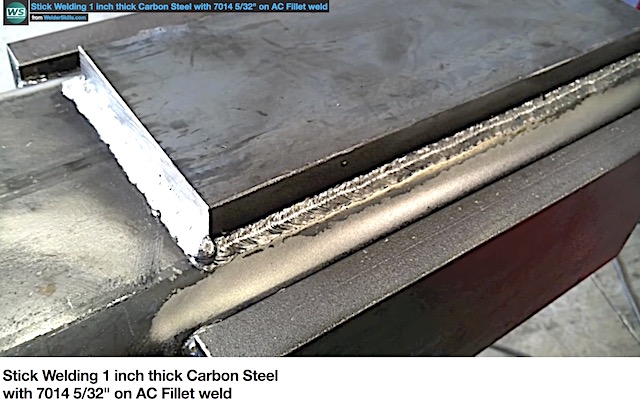

Stick Welding 1 inch thick Carbon Steel 175 amps with 7014 5/32" using AC buzz box - Fillet weld

- HOME

- STICK WELDING

- Stick Welding Carbon Steel

I was doing this job using a Lincoln 350 mp and pulse spray mig and when I got to these heavy counter weight plates, I thought to myself..." what if I ran out of gas or my 350mp stopped working or was down to my last contact tip" ???

So just to show what can be done with very simple equipment, I switched over to a Lincoln buzz box tombstone style AC welder and welded the plates using AC and 175 amps.

7014 rods burn similar to 6013 but lay down a heavier bead due to lots of iron powder in the flux.

7014 are an all position electrode but I could position the piece to a 2f fillet so that is what I did.

There was no requirement on the drawing for a certain process and since the plates were strictly for a balancing counter weight, I thought "why not"?

Having options can get you out of a jam.

scroll down for settings

7014 5/32" using AC

WELD PROCESS = SMAW, SHIELDED METAL ARC WELDING, STICK WELDING

METAL TYPE = CARBON STEEL

THICKNESS = 1” A36 PLATE TO 1/2” WALL TUBE

WELD TYPE = FILLET

JOINT TYPE = LAP TEE

POSITION = 2F

AMPS = 175 AMPS

POLARITY = AC

ELECTRODE = 7014 5/32"

ADDITIONAL SETTINGS =

TIPS: DIFFERENT MANUFACTURERS ELECTRODES REQUIRE SLIGHTLY DIFFERENT AMPERAGE SETTINGS.

WHEN AND WHY TO USE 7014 RODS

When low hydrogen electrodes like 7018 are not specified by a procedure, specification, or code, 7014 rods are sometimes a good option.

In the short video on this page, I was fabricating a fixture and the 1 inch plates being welded with 7014 5/32" were counterbalance weights.

Since the drawing did not specify the electrode, I decide to weld them with 5/32" 7014.

Some benefits to using 7014:

- Slag peels off easy (usually)

- dont require a rod oven in order to run well

- easy to get at a big box store like tractor supply, home depot, etc.