TIG Brazing vs Tig Welding

How Strong is Tig Brazing?

Is TIG brazing as strong as welding?

What are some common uses of Silicon Bronze filler rod?

silicon bronze TIG rod in stock at weldmonger.com

Just how strong is Tig Brazing?

The tensile strength on aluminum bronze ERCuAl-A2 rod is very similar to the er70s2 welding rod.

So why did the one sided fillet weld fail so easily on a fillet break test?

Several variables come into play.

one would be the amount of steel that got diluted into the braze.

(when you use tig for brazing, sometimes you melt some base metal and it mixes in with the braze metal and that can cause a brittle joint)

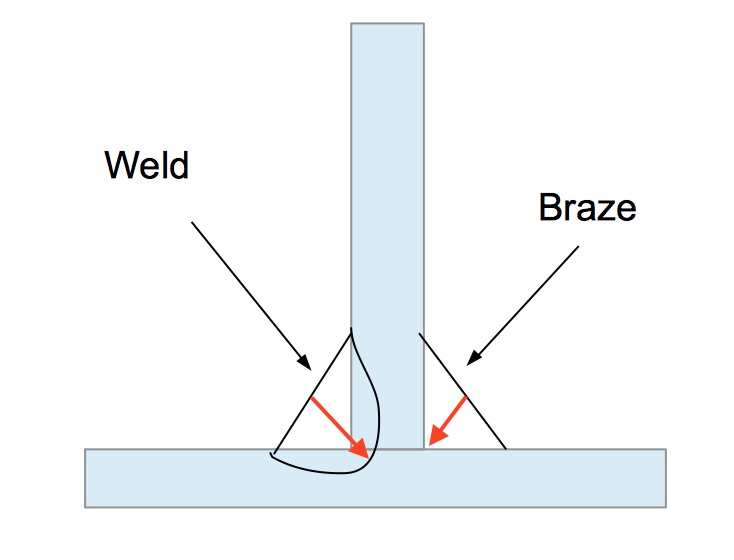

Another reason is simply the fact the cross sectional area of material is less than that of a weld due to zero penetration.

Is tig brazing as strong as welding?

just like you saw if you watched the video, the large braze joint on thin wall tubing that was done completely all the way around the coped joint had quite a bit of strength....

but the one sided braze joints were weak

What are some common uses of Silicon Bronze filler rod?

Joining copper to steel, cast iron to copper, brass to copper, copper to stainless...are just a few of the many uses of silicon bronze filler wire.

It grinds very easily too so many custom furniture makers are using silicon bronze on square tubing joints that can be tig brazed all the way around because the joint is very pleasing to the eye when it is sanded smooth.

A while back, I used silicon bronze rod to overlay a DIY hammer for the shop.

I used a large piece of scrap 2" round stock for the hammer head and overlayed both ends using silicon bronze.

That hammer became the favorite hammer of my machinist friend for bumping parts around on the lathe.

Silicon bronze makes a nice face for a machinists mallet because it is not as hard as a hard steel hammer face.

Silicon bronze has its place in a welders rod rack... but I would advise not using it for structural applications.

It did hold up well on the coped joint on thin wall tubing but I loaded that joint up with braze metal.

Conclusions...

For one sided joints like gussets, welding with er70s2 is better than silicon bronze or aluminum bronze.

for thin metal that can be brazed all the way around, TIG brazing can be pretty darn strong.

Aluminum bronze can be used on steel using similar settings as one would use on aluminum.

I need to drop a few pounds.

The AWS identifiers for these two rods are

ERCuSi-A for silicon bronze

ERCuAl-A2 for aluminum bronze