TIG welding basics part 2

This video answers a lot of questions that came out of part 1 "the big big TIG welding overview"

In

future segments, I will talk about tig torches, filler rod selection,

gases, tungsten, tig welding machines, and tig welding settings.

But for right now, I figured I would answer some questions that came out of the BIG TIG overview.

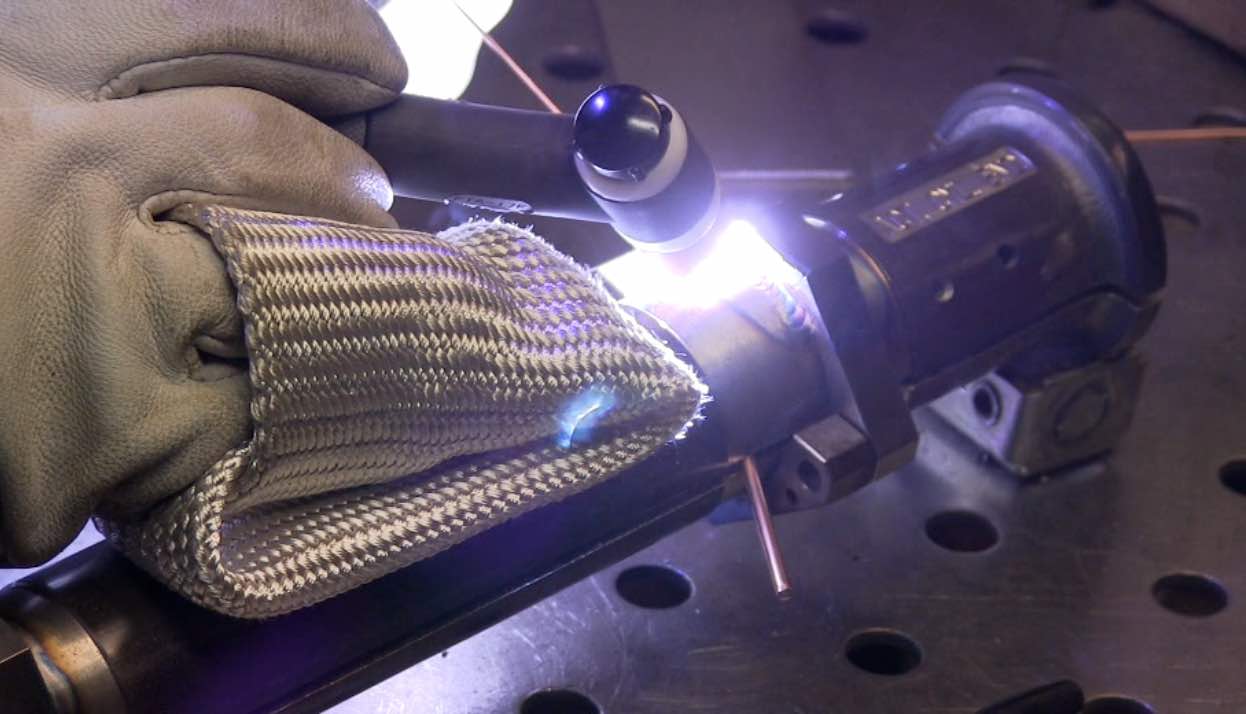

click the pic below to learn more about The TIG finger XL

Before I get into the real basics of Tig Welding like polarity, tig torches, machine settings, AC balance, AC frequency, and pulse settings, I thought I would answer a few questions that were asked on Part one.

Happiness is TIG welding with a tight arc

Question: my question is how close is

your tungsten to the puddle when doing TIG in AC and DC current? it

looks like you are actually touching the puddle, but we all know if it

was touching it would be smoked! that's my biggest problem, I get as

close as I can to the work material, but if I add rod, I run the risk of

smoking the tungsten.

Answer: I

typically hold a longer arc on AC aluminum than I would on steel. Just

because steel is more forgiving if/when you dip your tungsten.

Also, torch angle makes a lot of difference and can fool you . when you lean the torch back too much, the electrode can be really close to the puddle where the taper stops. The tip can look like its not too close, you add wire , the puddle rises, and before you know it you sputter.

Also, I use a technique that compensates for the way the puddle rises and falls as you add filler metal. ... I extend the arc while I add filler and hold a really tight arc while I travel ahead.

Tig basics? or too complicated at first

Question: I think if i had no knowledge about welding this would be to complicated. you should have explained some of the terminology and basic function of tig welding.

Answer: I will cover the basics along the way. Part 1 was a Big overview... I may have put the cart before the horse but the reason was to get a lot of questions.

Graphite for backing?

Question: When using a backing to build up a hole like on that wheel or the "bad mill" part you showed, is it possible to use graphite to use as a backing? I've known a few gunsmiths that used graphite rod when repairing the edges of screw holes that have been badly dinged or rusted. The tight fitting graphite sheds the rod and leaves a clean round inner surface, so all they have to do is flatten the weld down instead of trying to round the hole and risk being over sized.

Answer: Graphite is basically Carbon. So for alloys like Stainless steel, that is a concern because there can be a risk of carbon pick up. Adding carbon to stainless can destroy its corrosion resistance. Graphite rods are often used for stops for braze repairs on cast iron but cast iron already has quite a lot of carbon and braze metal can tolerate carbon pickup.

Scratch Start Tig for AC

question: Have you ever tried stratch start TIG with an AC Stick welder on alluminium? Does it work?

Answer: It only works if you have a high frequency unit. HF units are quite expensive so money is better spent toward an AC/DC tig welder.

question: Could you go over tungsten size and selection of different tungsten choices relative to what jobs or materials your going to weld? (Stainless, mild steel, aluminum, magnesium, titanium) Collets needed and any other helpful info you throw in for good measure.

Answer: I will go over all of those issues in future segments.

But ....90 % of all the welding I do can be done using a 2% lanthanated tungsten and a #7 gas lens cup.

question:When I walk the cup,my filler rod always balls up and comes out of my puddle. What can I do to avoid this?

Answer: whether walking the cup or not, a long arc along with too much torch angle can cause the rod to ball up and separate from the puddle.

hold a tight arc and dont use excessive torch angle..also, using a filler rod that is too small will cause it to ball up and separate from the puddle.

just because you are walking the cup does not mean you have to use the lay wire technique. Dipping the rod is also an option.

question;:I'm going to buy my first welding machine and its gonna be a decent chinese made dc TIG. But here's my question:

What is the the pulsingfunction mainly used for and is necessary or could it be useful for a hobbyist or engineering student.

Thx and greetz from Austria !

Answer: If you are just getting started with tig welding, pulse will not help you. You would be better off spending the money on extra metal and filler rod so that you can get more seat time and practice.

Pulsing does make a difference but only once you reach a certain level of skill. most tig welding jobs can be done without pulse.

question: I do a few cast iron and cast steel repairs every year, mostly for farmers on older or antique farm equipment. For most of them I generally braze using oxyacetylene, but I was wondering if tig brazing with aluminum bronze or silicon bronze would work as well. Also what would be the best procedure for this process. As I also do the machining, I can fix any boo boo's from either end lol.

Thank in advance, and I'm am looking forward to the rest of this series.

Answer: Tig welding cast iron using aluminum bronze or silicon bronze is definitely possible. The main thing is preheat and slow cool.

when I tig weld cast iron, I use AC settings along with very little cleaning action set on the AC balance.

Question:Jody, I've noticed that your tig tips are sometimes sharpened to a point and sometimes a full semi sphere. How do these shapes affect a weld?

Answer: Sometimes the reason for the different shaped tips is just simply that I sharpen electrodes for a crisp start at low amperage...and then just allow the electrode to ball however it will.

sometimes the tungsten balls more than I would like..but if it is welding ok, I just keep welding

see more tig welding videos