TIG Welding Carbon Steel Back to Basics

Watch a 10 part series on TIG Welding Carbon Steel Basics at the weldmonger store blog page

- HOME

- TIG WELDING

- Tig Welding Carbon Steel

Back to Basics - TIG Welding Carbon Steel

“If your TIG welds on steel look inconsistent, it’s usually not the machine—it’s one of these basics.”

Let’s walk through TIG welding carbon steel from the ground up, the same way I’d teach a student in the shop.

1. Cleaning the Metal (Non-Negotiable)

When it comes to TIG welding, Carbon steel is a forgiving metal compared to aluminum or stainless—but dirty steel will still still cause you problems.

Who needs problems? not me.

When a problem arises and you have taken a shortcut, it takes longer to figure out the problem...just another reason to avoid shortcuts

What to Remove for TIG welding

- Mill scale ( dont just polish over, remove it completely)

- Oil and grease

- Paint or coatings

- Rust

Best Practices

- Use an abrasive like flap disc if mill scale is light but thick mill scale sometimes requires a hard rock to completely remove. If finish is too rough after hard rock, follow up with a flap disc.

- Wiping with acetone or alcohol after grinding is a best practice but not always 100% required

- Clean all areas approximately 1/4” away from weld area

A clean weld starts before you strike an arc.

If the puddle looks jumpy or contaminated, look at the metal first—not the machine settings.

2. Tungsten Prep for TIG welding carbon steel

(Clean and Sharp Matters)

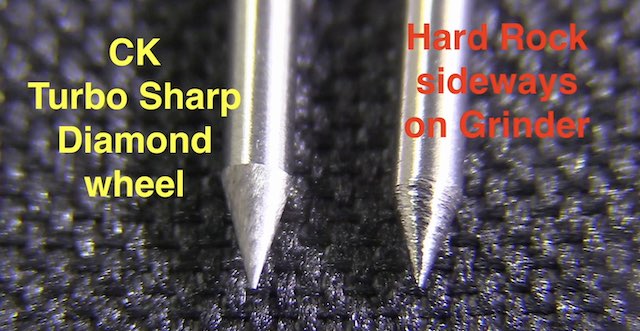

For carbon steel TIG welding, you want a sharp tungsten with grind lines running lengthwise, not sideways. .

If a smooth enough grinding wheel is used, the grind scratches make way less difference.

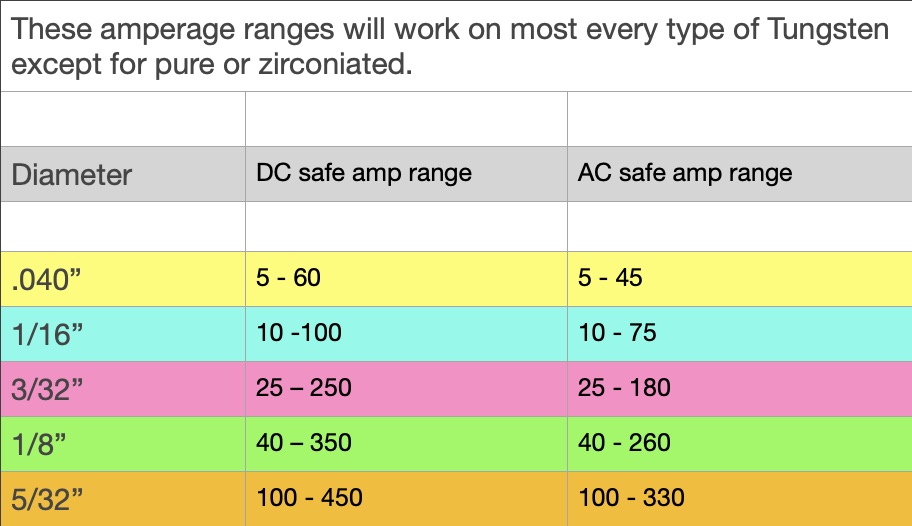

Tungsten Size (General Rules)

- 1/16” → thin material, low amps 1 amp - 100 amps

- 3/32” → most common, great all-around choice up to 200 amps

- 1/8” → higher amperage, thicker steel

A realistic amperage Tungsten amperage chart for tig welding carbon steel

Tungsten Tip Shape

I use less taper for higher amperage and more taper for low amperage

- Avoid contamination—regrind if you dip

A contaminated tungsten causes wandering arcs, dirty puddles, and frustration.

3. Filler Rod: Type and Size

Common Filler Choices

- ER70S-2 – excellent for clean steel, great puddle control

- ER70S-6 – handles slightly dirtier material better

Filler Rod Size Guidelines

- .030” or .035” for thin metal like auto body (mig wire works too and you can straighten it by twisting it under tension using a drill.

- .045” small fillets up to 11ga

- 1/16” → for 16 ga to 11ga

- 3/32” → most common size 1/8” to 3/16”

- 1/8” → thicker joints, higher heat

Don’t force feed the puddle.

If the rod chills the puddle drastically, it’s probably too big.

4. Gas Cup Setup & Shielding

If you are still using the standard TIG cups and hardware that came with your machine or TIG torch, I can just about guarantee you will get better results if you upgrade to a weldmonger® stubby gas lens kit.

Good gas coverage protects the molten puddle and the tungsten.

Basics That Work

- Argon shielding gas

- Start with 2-3 CFH per cup size, example: A #10 cup needs 20-30 cfh and a #8 cup needs 16 to 24 CFH.

- Use a cup size and electrode extension that allows you to see the puddle and tip of electrode clearly

Gas Lens Advantage

- Smoother less turbulent gas flow

- Better gas coverage

- Allows a bit more tungsten stick-out

If your metal has been properly cleaned, and the bead still looks dull or crusty, and you are still using the standard cups that came with your torch, try switching to a gas lens setup before changing machine settings.

5. Torch Type & Size Considerations

You don’t necessarily need a water cooled torch to weld carbon steel—but A water cooled 20 style torch gives you lots of great features and options.

Key Considerations

- Smaller torch = less fatigue, gas lens setups are readily available and less expensive and a small torch can fit into tighter areas

- Comfortable = steadier hands

I personally often use an air cooled 17 style torch along with stubby gas lens hardware along with gas lenses and furick cups for most of my carbon steel and 4130 welding. ( the jazzy 10 ceramic is a great choice)

I like the simplicity of an air cooled torch and not having to listen to the extra noise from the water cooler.

But when higher amps or for continuously welding production parts, it makes sense to use a water cooled setup. The torch never gets too hot with water cooled and since time is money, you dont want to have to stop to let a torch cool off.

6. Feeding Filler Wire the Right Way.

This is where many beginners struggle.

Key Points

- Keep the hot tip of the rod inside the argon

- Dab smoothly—don’t stab the puddle

- Move the torch first, then add filler

- The puddle melts the filler rod so feed into puddle, not the arc.

- If the rod tip oxidizes between dips, it’s leaving the gas shield.

There is no way to learn feeding filler except by doing it.

Here is a video on feeding the filler wire…

7. Practice Drills (Where Skill Is Built)

Before welding joints, practice beads on plate.

Drill 1: Straight Beads

- Focus on arc length

- Watch puddle size

- Keep consistent travel speed

TIG welding a bead without filler metal ( a beginner drill)

TIG welding a bead with filler metal ( a beginner drill)

Drill 3: Padding Beads

- Stack beads side by side

- Maintain even spacing

- Same heat, same rhythm

If your beads aren’t consistent on flat plate, welding tee and lap joints will only burn up metal.

“TIG welding carbon steel isn’t about fancy settings.

It’s about clean metal, sharp tungsten, proper filler, good gas coverage, and practicing the right way.”