Walking the Cup TIG Welding Videos

- HOME

- TIG WELDING

- Walking the Cup Tig

This first Video is How to get practice walking the cup on plate with a Scratch Start TIG

Practicing Walking the Cup on Stainless and Carbon

Walking the Cup TIG Welding Pipe

Cup Size Matters for Walking the Cup

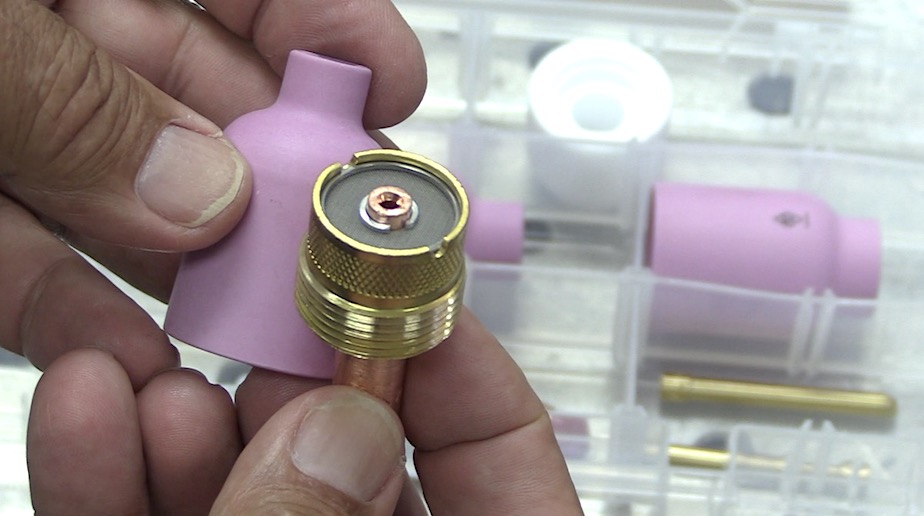

Our new LArge Diameter Gas lens kit now comes with 5/32" setup for those high amperage jobs

Walking the cup is a TIG welding technique that is mostly used on pipe and socket welds but also works on long fillet welds provided the scratches it leaves behind are not a problem.

Walking the cup is like walking a 55 gallon drum across a shop floor and when done correctly, can make a very uniform weld with uniform ripple pattern.

When you Should NOT to Walk the Cup

- On precision machined surfaces where the scratches left behind are unacceptable

- On small bore pipe 1" and smaller ( unless you are good at walking the cup on small diameters pipe or tubing)

- When there are other pipes, a wall, the floor or other obstacles in the way that won't allow for it.

- When the test supervisor tells you not to. ( yes this does happen and since he is the gate keeper, you are better off complying)

- If the WPS prohibits walking the cup ( I personally have not seen this but have heard of it)

Freehand vs Walking the cup TIG Video

Freehand vs Walk the Cup is a silly argument.

Neither is better. They are just different

Walking the cup tends to be better when there is plenty of room around the pipe with no obstacles or restrictions due to a wall or another pipe being in the way. That is where freehanding comes in.

Free hand tends to work better it tight spots where walking the cup is not practical.

Small bore pipe and tubing is another situation where free hand can be better. Walking the cup becomes more difficult once you get below 2" pipe.

Some welders can probably walk the cup on one inch pipe but free hand is easier for most of us.

Freehand technique on 4 inch pipe

Walking the Cup TIG Welding Socket Weld

Socket welds are often welded by walking the cup except when stuff is in the way.

Fabbing socket welds in a tripod vise with nothing in the way definitely goes faster when you walk the cup.

But even in a tripod vise, small socket welds like 1/2" are sometimes easier to free hand.