Welding metallurgy of Aluminum alloys..Day 4 of Down and Dirty Metallurgy

Learn more about welding Aluminum Down and Dirty Welding Metallurgy of Aluminum and aluminum alloys

Aluminum is different from other metals in that it has an oxide skin on the surface that has to be broken down before you can effectively weld it. That’s what TIG welding on alternating current does, The reverse half of the alternating current cycle is what breaks up the oxides.

Some of the aluminum alloys are heat treatable. Does that mean the alloy will harden if you heat it up and cool quickly? If you have been paying attention to days 1-3 you know the answer. Remember reading that carbon and low alloy steels, cast iron, and some 400 series stainless steels harden by heating and then quick cooling? And that practically every other metal actually got softer by heating and then quick cooling? And that you needed to understand that before going any further? Well it is day 4 of the course now and we are talking about aluminum alloys. Are you getting it yet? Well, what’s the answer? Have you been paying attention? The answer is …….NOPE…

In fact if take a piece of heat treated aluminum and heat it up really hot and then dunk it in cold water, it will get much softer than when you started. That’s because the way aluminum is heat treated is by holding it at elevated temperature, ( sort of like nickel alloys). I will say it again:

Carbon and low alloy steels, cast iron, and some 400 series stainless steels harden by heating and then quick cooling? And that practically every other metal actually got softer by heating and then quick cooling?

Aluminum and aluminum alloys

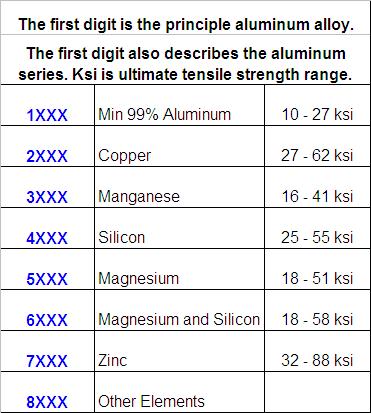

1100, 3003, 5052, 6061 These are the most common alloys welded

1100 is pure aluminum and is not heat treatable 2024 is alloyed with copper buy is not considered weldable for critical applications 3003 is alloyed with manganese and is work hardenable, but not heat treatable

5052 is alloyed with magnesium and is not heat treatable 6061 is alloyed with magnesium and silicon and is heat treatable 7075 is alloyed with zinc but is unweldable by conventional processes…There is a new process called Friction stir welding that can welding 7075. You can Google it and find plenty of information on friction stir welding and friction stir welding welding metallurgy .

Another important thing to remember about aluminum welding welding metallurgy is that aluminum is hot short. What is hot short? No I am not talking about the shorts Jessica Simpson wore in Dukes of Hazard, the term hot short means that unlike other metals that get more ductile or bendable when they get hot, aluminum actually becomes brittle at certain elevated temperatures. That’s why welding aluminum without filler metal is usually a horrible idea. The stress from shrinkage of the puddle combined with the hot shortness will cause cracking. Especially if you start on the end of the piece being welding. That being said, it is a good idea not to start on an end, but rather weld to an end. Another consideration for Aluminum welding welding metallurgy is something called liquation cracking. It really goes along with the whole hot short thing. What happens is that if you are welding aluminum and almost penetrate thru but not quite. The grain boundaries of the metal are weak under heat and stress and will sometimes open up into cracks. This happens a lot on sheet metal thicknesses when partial penetration fillet welds are called out.

Aluminum Alloy Chart

Woud you do me a favor and give me some suggestions on how to make "Down and Dirty Metallurgy" better? Is it too simplified? Is it useful?

Learn more about TIG welding Aluminum Leave Down and Dirty Welding Metallurgy