Welding Stainless -Tip for Tigging Stainless

Tip for Tig Welding Stainless Steels – or tig welding down in a hole – or in a real tight spot on most any metal. Get a Furick #12 tig cup (fupa12) either clear or ceramic.

How I Discovered the Benefits of a 12 tig cup

From YouTube videos and welding school, its easy to get the impression that all welding is either done on pipe, or flat plate right in front of you and easy to get to

…don’t believe it.

The real world of welding throws all kinds of curves at you.

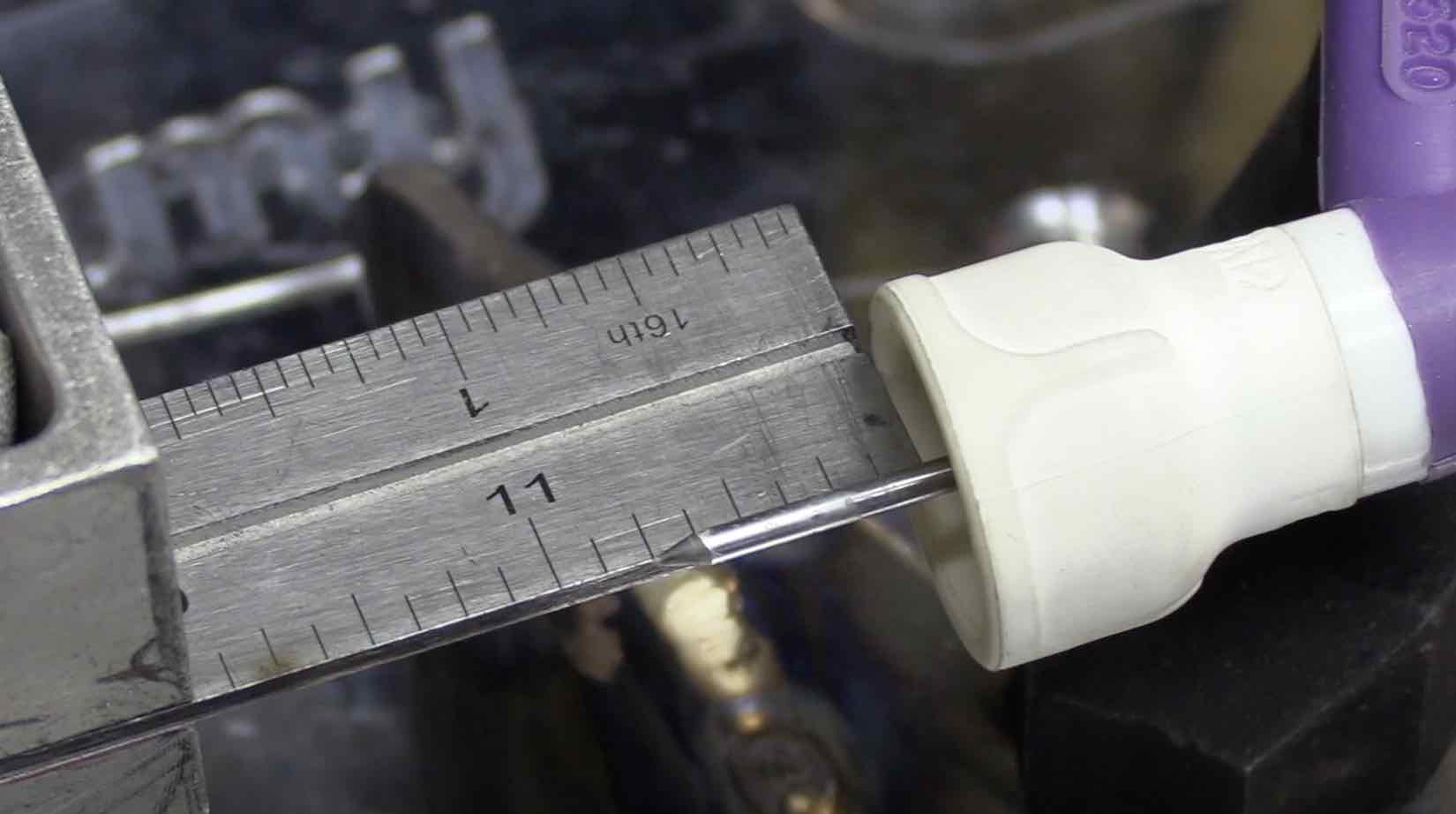

Sometimes you need to make a tig weld in an area you can’t get to easily…like down in a hole…or a really tight corner like on a cluster weld on a 4130 chromoly airframe....or welding the corner of a drip pan from the inside. And if you have done that many times, you know that sometimes, if you extent the tungsten too far, you lose your gas coverage.

I mean let’s face it, you can only push argon out there a certain distance no matter how high you crank up the flow. More shielding gas flow is not always better because it can suck air and make things worse.

That’s where this tip for welding stainless and other alloys comes in handy…this is how to extend that electrode way out there and still get good coverage…and once you have welded with a cup like this in tight spots, you will probably discover all kinds of uses for it because For some metals, it just plain makes the puddle flow better and makes the welds look better too.

Read on to learn why....

If all your tig welding stainless steel has been on 300 series stainless steels, you are probably wondering what the heck I am talking about because all 300 series stainless like 304 and 316 welds great.

But there are like a hundred other lesser known grades of stainless steels and trust me, not all stainless steel welds the same…and better argon shielding sometimes makes all the difference on the problem stainless steels…especially the ones used for aircraft engine parts.

Welding stainless is normally cake, but for certain alloys like 17-7 stainless, 15-7 ph stainless steel, inconel 718, and a bunch and others, that have a pretty sluggish puddle, having a little more gas envelope means getting a little bit more forgiveness on keeping that hot tip of the rod shielded. A bigger argon evelope keeps the oxidation out of the puddle and keeps the puddle cleaner.

A cleaner puddle flows with less amperage and less amperage sometimes means less distortion.

Yes , this does require a little more gas flow than a #7 cup, but not all that much . About 25 cfh was used for the demo in the video.

This is not something you want to do all the time especially if you are the one paying for the argon because you don’t always need the extra gas coverage and the big cup uses more argon. But there are times when it will get you out of a pickle..

Aircraft and aerospace tig welders use oversized tig welding cups all the time and not just on titanium.

They use them on Hastelloy X, Inconel 718, 17-7, 13-8, 15-7 stainless, Waspalloy, inconel 713c, and lots of other high temp alloys that have small quantities of aluminum mixed in for heat treatment response. Aluminum that is alloyed in stainless steels and nickel alloys, even is small percentages , makes the puddle sluggish.

For tig welding the sluggish alloys mentioned above, a Fupa12 furick cup really helps in making a tight clean weld.

The Furick #12 cups are designed to be used with both air cooled and water cooled tig torch ..both 9/20 style and 17,18,26 style tig torches.

For 9/20 style torches, you will need a 45v44 gas lens collet body

For 17,18, 26 style torches you will need a furick adapter kit.

exit tip for welding stainless and see more tig welding tips