How to TIG Weld Aluminum

- HOME

- TIG WELDING ALUMINUM

- How to Tig Aluminum

- How to Tig Weld Aluminum

There is a reason so many top welders like a #5 cup for getting full penetration on aluminum. learn more at weldmonger.com

This #5 combo kit includes a clear #5 as well as a ceramic #5 cup along with collet body and all the parts needed to fit your torch. We have a kit for #9-20 style torches as well as 17, 18, 26 style .

How to tig weld aluminum and Why we use AC (alternating current)

DCEN is used for steels, stainless steels, nickel alloys, titanium, and lots of other alloys.

But DCEN does not do anything to break thru the oxide film that is on all aluminum.

DCEP provides a cleaning action that breaks up aluminum oxides but the problem is that the electrode gets so hot and balls up when welding with DCEP.

AC is a mixture of Electrode positive and electrode negative.

so AC provides some of the benefits of DCEN as well as some benefits of DCEP...without having too much of the down side of each.

That is why Aluminum is most often TIG welded using AC (alternating current)

How to TIG Weld Aluminum Corner joints, Butt joints, and lap joints

How to TIG weld a Vertical 3g .063" Butt Test joint

How to TIG Weld Aluminum Tee joints

How to tig weld aluminum - a thin .063" tee joint fillet weld

Tig welding .063" (1.6mm) aluminum 1G butt

see more tig welding aluminum videos or go to the main TIG welding page

Cleaning Aluminum prior to welding

Do you really need to wire brush all aluminum before welding?

I say no.

There is a difference between brand new aluminum sheet and an aluminum ladder that has been on a ocean boat.

The oxide layer on the new aluminum sheet will be relatively thin and does not usually require any wire brushing or cleaning other than maybe an acetone wipe to remove oils or tape residue.

Customers do not want to see wire brush marks next to the weld on polished or brush finished aluminum.

An aluminum part that has been exposed to the elements has a thicker oxide layer and might even have some corrosion.

this is where mechanical cleaning is helpful.

And if there is a plasma cut edge, of course the dross needs to be removed

there are a lot of methods used for cleaning aluminum. Sometimes a stainless steel wire brush is enough.

But other times, a sanding disc, or scotch brite type roloc wheel is needed.

An acetone wipe after abrasive cleaning helps to remove any residues.

Shielding Gases for TIG welding aluminum

start with pure argon.

Argon might be all you ever need.

But if you start specializing in thicker aluminum, mixing helium speeds up the welding and makes for a cleaner puddle.

Yes helium has become very expensive, but only a tiny bit is needed to make a difference. I barely float the ball most of the time so a cylinder of helium lasts me a really long time.

There are also other options for shielding gas like Stargon AL (from praxair) which is a blend of argon with some trace amounts of active gases like nitrogen.

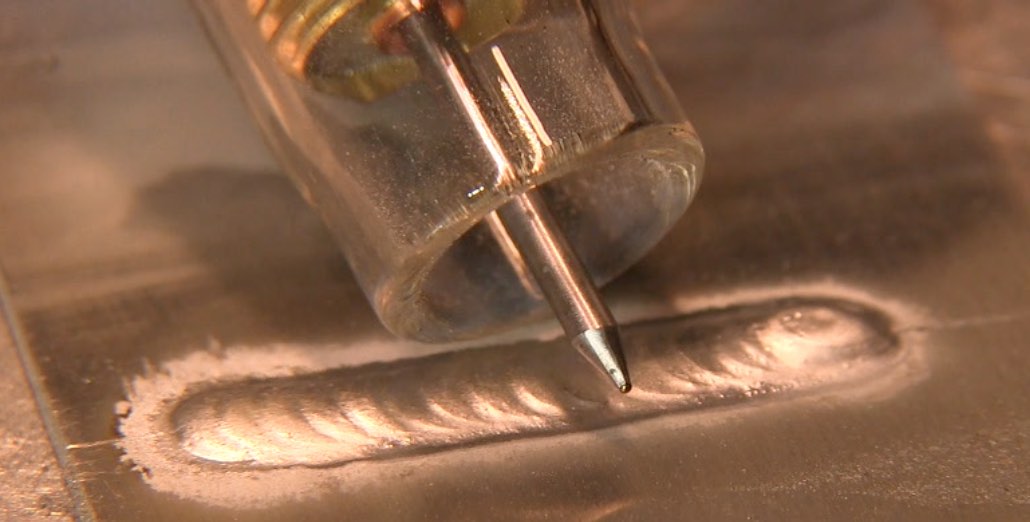

Tungsten Electrodes ...type and size

I use 2% lanthanated for everything. It is literally all I need.

That makes life simple too because I can cut my electrodes in half and sharpen both ends and remove the blue color coding if I want to.

I dont have to worry about mixing up the different types of electrodes.

I use 3/32 mostly.

occasionally, I use 1/8". But 3/32 will weld very thin metal with a tapered point....and will take me up to around 200 amps without needing to go to a 1/8" electrode.

If I needed to weld really thick aluminum, I would invest in some 5/32" electrodes and torch hardware.

Other tungsten electrodes that work on aluminum

I like 2% lanthanated but that doesnt mean its the best for every single application.

In fact, I would say that there is no 1 single tungsten that is best for everything.

There is only a best tungsten for a certain application.

2% Ceriated (gray) works very well on AC too but just wont handle high amperages as well as 2% lanth.

Some folks really like the LaYZr (Chartreuse) from CK for Aluminum.

Again, it depends on what machine you have, amperage needed, AC frequency used, AC balance, Amplitudes, and more so it all boils down to what works best for your application.