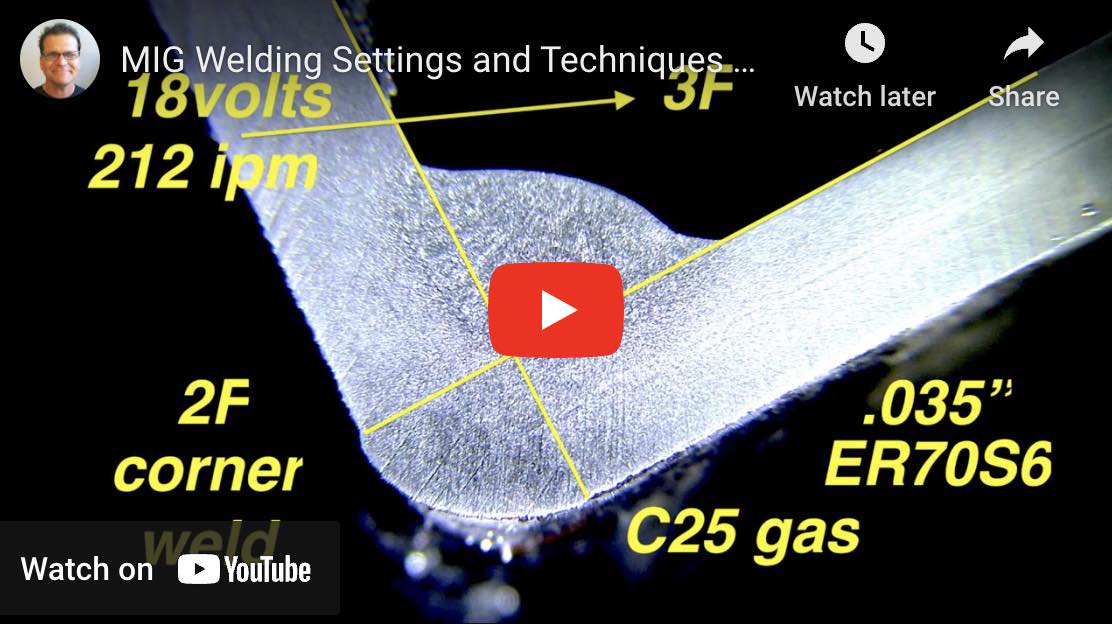

115 volt MIG Welder 11ga Corner joint 1F Flat position using a primeweld mig180

Details and settings used for this joint.

115volt mig welder - Primeweld Mig180 dual voltage mig welder

material - 11ga steel (1/8") thickness

voltage 18.1

wire feed speed set to 149 inches per minute ( much lower than recommended on chart but works better for this joint)

.035" ER70S6 wire

C25 shielding gas also called 75/25 argon/co2 gas at around 20-25 cfh

I used a PrimeWeld MIG180 for this video which is a dual voltage mig welder that runs off either 115 volt or 230 volt power.

I had it plugged in to a standard 115 volt outlet on a 20 amp breaker.

I have also used in with 230volt power but for this thickness 115 volt power works fine.

I filmed several other videos using this welder along with complete settings listed on each page and you can see those here at the main primeweld mig180 page .

Not matter what type of welder you have, I hope these videos help you learn how to use it better.

And if you are in the market for a 115volt mig welder, or dual voltage mig welder, I hope these videos help you with your buying decision.

learn more about the MIG 180 at weldmonger.com

These mig videos serve as a really good mini course on short circuit mig welding no matter what brand of mig welder you have

I think of my Mig180 mostly as a Great Little MIG Welder with a great arc and nice small mig gun that feels great in my hand... but it also Stick welds, and even comes with a spool gun for aluminum.

just look at all that comes with it... That is a lot of bang for the buck!

General Tips that help with MIG Welding

Clean mill scale with a grinder. Clean metal welds better.

I am not saying that everyting needs to be perfectly free from mill scale because things like square tubing only have a very light mill scale coating and do not need to be ground clean. But heavy mill scale on hot rolled steel plate, needs to be ground clean for best results.

make sure your ground is secure and clamped on clean bright metal.

Having good ground is very important on short circuit mig welding and can prevent an erratic arc and will give you nicer restarts.

Keep your stickout short...less than 1/2" (stickout is the amount of unmelted wire stickout out from the contact tip when welding, and for short arc mig, should be kept to 1/2" or less.)

Use recommended settings for flat and horizontal welding but reduce settings for vertical uphill.

Chart settings are usually pretty good for flat welding on the workbench but for vertical uphill welding, are often way too hot.

One easy way to get around this is to use the recommended chart settings for one or even two thicknesses less than what you are welding and also reduce wire speed by about 10-15 %.