316L Stainless Steel TIG welding

- HOME

- Tig Welding Stainless

- Tig Welding Stainless Steel

- 316L Stainless

When Is 316L Stainless Preferred Over 304L?

Why Stainless Steel Grades Matter

Choosing the right grade of stainless steel isn’t just about picking a shiny metal. It’s a strategic decision that affects the durability, performance, and longevity of everything from surgical implants to offshore drilling equipment. Among the most commonly compared grades are 304L and 316L—both are low-carbon versions of their respective base grades and highly corrosion-resistant, but one isn’t always interchangeable with the other.

Common Confusion Between 304L and 316L

Many people assume that stainless steel is all the same.

Spoiler alert: it’s not.

The subtle differences in composition and properties can be the deciding factor between a part lasting a decade—or rusting out in just a few months.

While 304L is a reliable all-purpose stainless steel, 316L is the heavy-duty alternative you turn to when things get harsh. But when exactly should you use 316L over 304L?

Let’s break it down.

What Is 316L Stainless Steel?

Chemical Composition

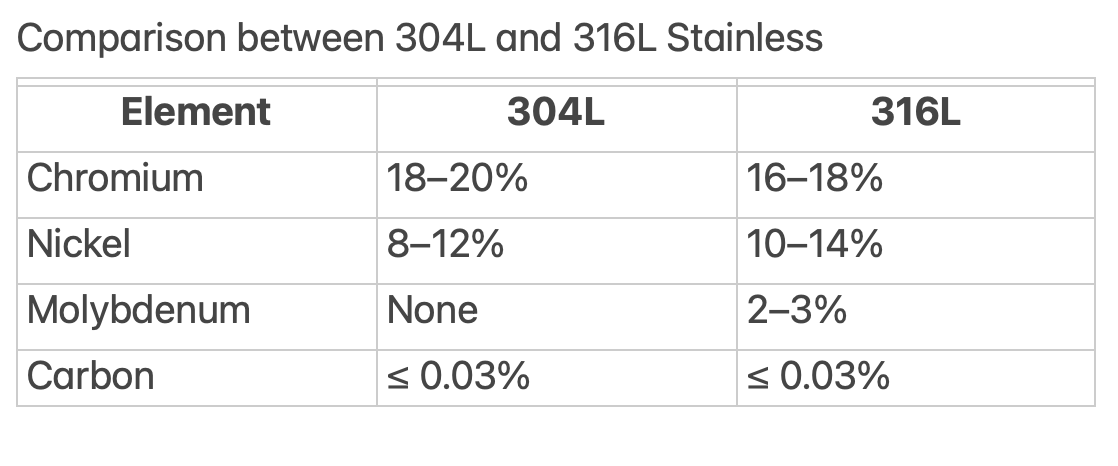

316L is an austenitic stainless steel like 304L, but with one critical addition

—molybdenum, typically around 2–3%.

This single ingredient transforms its performance in aggressive environments. Here's how the two compare in terms of composition:

Key Differences Between 304L and 316L stainless

- Corrosion resistance: 316L has superior resistance to chlorides and other corrosives.

- Strength: Both are similar in strength, but 316L holds up better in harsh environments.

- Cost: 316L is more expensive due to molybdenum and higher nickel content.

The Role of Molybdenum in 316L

Molybdenum is the key factor when it comes to using 316L. It increases the steel’s resistance to pitting and crevice corrosion—issues that plague 304L in salty or chemical-rich settings. Even a few parts per million of chloride ions can wreak havoc on 304L, but 316L handles it like a champ.

Resistance to Chlorides and Acids

If your application involves seawater, de-icing salts, or acidic conditions (like sulfuric, hydrochloric, or acetic acid), 316L is the way to go. It’s commonly used in environments where corrosion isn’t just a possibility—it’s inevitable.

Marine and Coastal Environments

Boats, docks, and anything exposed to salt air or seawater demand 316L. Why? Salt is one of the biggest enemies of stainless steel. While 304L might look good for a while, it will pit and rust in these conditions. 316L’s molybdenum content makes it resilient in salty air, splash zones, and even full immersion.

Chemical and Petrochemical Plants

In facilities handling corrosive fluids or vapors—like chlorine, sulfur compounds, or strong acids—304L simply doesn’t cut it. 316L can withstand this chemical assault without losing structural integrity or corroding prematurely. That’s why it’s widely used in pipelines, tanks, and chemical reactors.

Medical and Surgical Applications

Biocompatibility is another key strength of 316L. It resists corrosion from bodily fluids and is well-tolerated by human tissue. Surgical instruments, implants, and orthopedic devices are often made from 316L due to its ability to remain stable and safe inside the body.

Pharmaceutical and Food Processing Equipment

When hygiene is critical and cleaning involves aggressive sanitizers, 316L offers superior resistance to both pitting and contamination. It’s ideal for cleanrooms, lab settings, and food-grade environments where trace corrosion can compromise safety or product quality.

What about high temperature applications?

Neither 304L or 316L are well suited for high temperature applications.

this is where 321 stainless excels.

Comparing 304L and 316L TIG Welding techniques and procedures?

Both 304L and 316L are austenitic stainless steels frequently used in industries that demand high corrosion resistance and clean, aesthetic welds—think food processing, chemical handling, and architecture.

While these grades are quite similar in many ways, subtle differences in their composition lead to specific TIG welding considerations.

- 304L is the “workhorse” stainless steel: versatile, affordable, and weld-friendly.

- 316L steps it up with added molybdenum, enhancing its resistance to chlorides and acids.

304L Overview and Weldability

304L contains 18–20% chromium and 8–12% nickel, with low carbon content (≤ 0.03%) to prevent carbide precipitation and intergranular corrosion. It’s the most commonly used stainless.

316L Overview and Weldability

316L has similar chromium and nickel content but adds 2–3% molybdenum, improving pitting and crevice corrosion resistance.

This makes it ideal for marine, pharmaceutical, and food-grade applications. However, the molybdenum increases its tendency to retain heat, which must be carefully managed during welding.

Chromium/Molybdenum in 316L:

- Lowers thermal conductivity

- Increases oxidation at high temperatures

- Makes the metal slightly more prone to heat tint and sensitization if overheated

These differences call for tighter control during TIG welding.

TIG Welding Preparation Best Practices

Cleaning Procedures for Both Grades

- Remove oil, grease, and contaminants using acetone or alcohol.

- Use dedicated stainless brushes (not carbon steel) to avoid cross-contamination.

- 316L needs extra attention to remove surface salts or chlorides, especially in marine-related repair applications.

Shielding Gas and Gas Coverage

Recommended Shielding Gases

- Use 100% argon for most TIG welding.

- some weld procedures call for a mix of argon with up to 5% hydrogen to improve weld wetting and reduce porosity (experienced welders only).

Gas Flow Rates and Coverage Strategies

- Torch gas flow rates depend mostly on type and size of TIG cup. 2-3 CFH (cubic feet per hour) per cup number will usually get you right in the ball park but other factors like joint type, and wind can affect the flow rate needed.

- Use a gas lens on the TIG torch to ensure even gas coverage and to allow for longer stickouts when needed

Back Purge Requirements

- Both 304L and 316L require back purging when welding tubing, piping, or any situation where the root side of the weld is exposed.

- Argon is recommended for back purging; Flow rate depends on volume of pipe, vessel, or part being purged.

- A dual flowmeter can come in clutch for purging.

Post-Weld Cleaning and Passivation

Pickling and Passivation Needs

- Both grades benefit from acid pickling and passivation post-welding to restore corrosion resistance.

- thorough passivation is more critical, especially in chloride-prone environments.

Common Weld Defects and How to Prevent Them

304L-Specific Defect Risks

- risk of intergranular corrosion if overheated.

- Occasional porosity if contaminated, but generally forgiving.

316L-Specific Defect Risks

- More prone to heat tint and oxidation at lower temperatures.

- If overheated, may lose molybdenum at the surface, reducing corrosion resistance.

Long-Term Weld Performance Considerations

Corrosion Resistance of Weld Zones

- Proper cleaning and passivation are essential to match base metal corrosion resistance.

- 316L is more corrosion-resistant, but improper welding can negate that advantage.

Mechanical Integrity and Fatigue Resistance

- Both grades offer excellent toughness and ductility post-weld.

- 316L outperforms 304L in harsh chemical or saltwater environments over time.

Conclusion

While TIG welding practices for 304L and 316L are largely similar, minor differences in thermal conductivity and molybdenum content demand more careful handling of 316L. Use lower heat input, tighter interpass temperature control, and thorough post-weld cleaning to ensure optimal results. In most other respects, best practices like clean fit-up, proper shielding, and good gas coverage apply equally to both 304L and 316L stainless steels.

FAQs

1. Can the same TIG settings be used for both 304L and 316L?

Mostly yes, but 316L benefits from slightly lower amperage and faster travel speed to reduce overheating.

2. Is back purging required for both grades?

Yes, especially for full-penetration joints or tubing to prevent root oxidation. A dual flowmeter is a convenient way to back purge while only needing one tank of argon

3. What’s are common mistakes when welding 316L?

using a filler metal other than ER316L.

Overheating, which can burn off molybdenum and reduce corrosion resistance.

using carbon steel wire brushes to remove heat tint

5. Are both materials equally forgiving in welding?

304L is slightly more forgiving. 316L demands more precise heat and cleaning control.