Discolored Stainless Steel Welds

watch more videos on TIG welding stainless steel here

- HOME

- TIG WELDING

- Discolored Stainless Steel Welds

Weld Color and Heat Tint: What It Means on Stainless Steel

When TIG welding stainless steel, the color of the weld bead can tell you a lot about how well the weld was made and whether the corrosion resistance of the stainless has been compromised. This article explains what those colors mean and how to control them.

Why Color Matters

Stainless steel forms a protective chromium oxide layer that prevents rust. When overheated or exposed to oxygen during welding, that layer oxidizes and changes color—also known as “heat tint.” These colors indicate a loss of corrosion resistance, especially in critical applications like food processing, medical, and marine.

Causes of Unwanted Heat Tint

- Insufficient shielding gas

- Too much heat input

- excessively Slow travel speed

- Dirty base material or tungsten

- Incorrect torch angle or cup size

How to Control Heat Tint

1. Optimize Shielding Gas Coverage

- Use a gas lens for better coverage Either a large diameter gas lens setup or something like a Furick jazzy10 or Fupa12

- Increase cup size for wider gas envelope (#10 or larger)

- Use post-flow of 10–20 seconds

2. Control Heat Input

- Use pulse settings on thin sections

- Move steadily, avoid lingering

- Use chill blocks to manage heat

- get puddle going quickly to avoid heat buildup

3. Clean and Prep Properly

- Wipe with acetone before welding

- Use a dedicated stainless wire brush

- Keep tungsten sharp and clean

Post-Weld Cleaning Options

If discoloration appears:

- Stainless wire brush: Use immediately while weld is warm

- Pickling paste: Acidic solution to remove oxide

- Electrochemical cleaners: Quick and effective for production

- Mechanical polishing: Scotch-Brite or light abrasives

Industry Standards for Stainless heat tint and discoloration.

Some industries have strict standards:

- Food-grade/sanitary: Often require bright silver finish

- Pharmaceutical: Zero color permitted

- Aerospace/Pressure Vessels: Weld coupons often tested for oxidation and penetration

The color of your stainless weld is more than cosmetic—it's a signal of quality, heat control, and corrosion resistance.

Question from reader about Discolored Stainless steel welds...

"I was wondering about the discoloration of Stainless steel TIG welds . Sometimes i get a beautiful rainbow coloration of the welds and sometimes they are just gray and plain looking. Can you give me any advice on how to keep them getting the "rainbow" coloration?

I seems low heat is the key as more turns it gray, but with the lower heat i fear poor penetration..

I Do custom automotive fab and make headers for turbo cars from 304L and all my competitors have beautiful rainbow welds. What can i do to get on par with the competition?"

Thank you

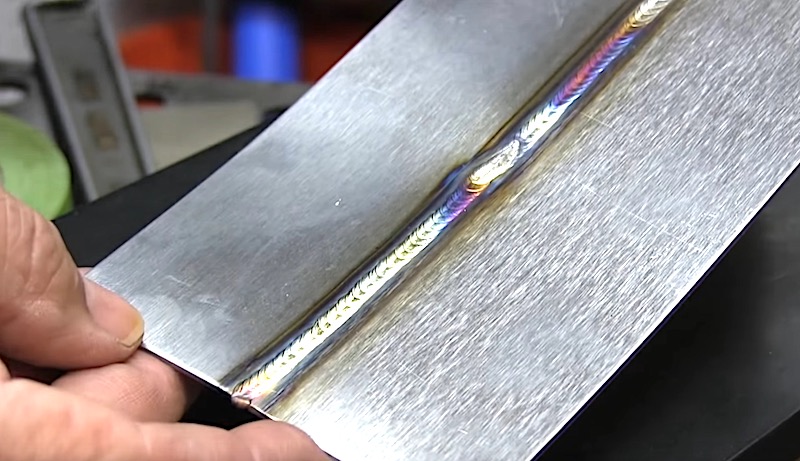

slightly discolored stainless weld

much better shielding on stainless weld

Response from weldingtipsandtricks.com on stainless steel welds

Discoloration is oxidation. It is just a matter of the argon shielding envelope leaving the hot metal before it has a chance to cool enough to not oxidize.

That is why gas welding steel with an oxyfuel torch looks so gray all over. If you were to use a really large tig nozzle, things would improve. ( I use a 15/16" nozzle/cup routinely but when I dont need it I use a small one to save argon)

There are also other ways to accomplish the same thing, watch your heat input, use a large nozzle, use chill bars to suck the heat out quickly, or stop often to let cool. Also you may be a little too concerned about penetration. Most of your welds on headers are fillet welds with maybe a few laps and butts. Stainless has a tendency to bond really well with low heat as long as it is clean.

Unless your beads look really cold and ropey, you are probably ok. Since you mentioned that sometimes you get good luster on your stainless welds, I think we can assume that everything is working ok. but just to make sure.....

Try this simple test... use a sharp electrode and set everything for steel... and hold the torch just like you were going to run a bead.

Get a piece of scrap steel and grind a small clean spot to shiny bright metal. Next just Puddle a small 1/4" puddle for about 10 seconds. let off the pedal and dont move the torch. hold it completely still until everything cools. Metal, tungsten etc. probably another 10 seconds.

Now look at the steel and also your electrode.

If your electrode is not completely shiny, you have some argon contamination.

It could be from a faulty collet body, a leak, or....

it could be a bad bottle of argon.

Look at the steel where you welded also, you should have a symmetrical shiny circle with no heat tint.

If you dont , or you have a odd shaped shiny area with heat tint bleeding in, its probably a bad collet body, or could be the collet in backwards.

let me know the results. I had the same problem once when I was out of town training some welders on a dynasty 200dx.

It was a bad gas lens collet body...right out of the box it was bad.

I also had a bad bottle of argon once when I first got my dynasty.

exit discolored stainless steel welds for more tips on welding stainless steel