Why Aluminum Cracks During Welding — Hot Shortness, Liquation Cracking & More

scroll down for short video on aluminum cracks

Demonstration of Hot Shortness in Aluminum and why Filler metal is almost always needed when TIG Welding Aluminum

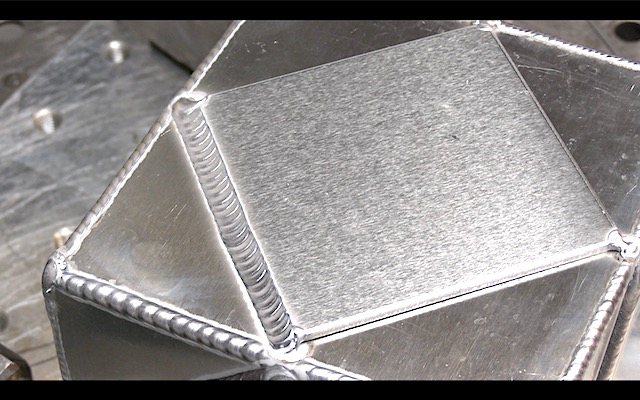

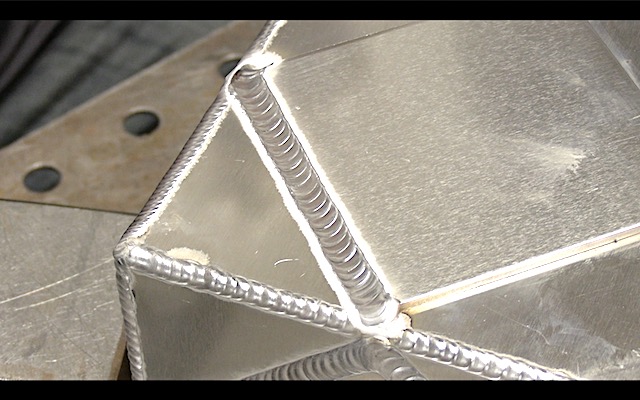

Aluminum Lap joint Tips using Clear Cups

- HOME

- TIG WELDING ALUMINUM

- How to Tig Aluminum

- Aluminum Cracks From Welding

see more videos on TIG welding Aluminum

Video Shows 7 Tips for TIG Welding Aluminum

...Introducing the New WeldMonger Challenger TIG kit that includes the most frequently used Cups.

Aluminum Cracking issues

Welding aluminum can be tricky — it’s a soft, highly conductive group of alloys with a ton if different alloy designations and tempers, and it doesn’t always behave like steel.

One of the most frustrating problems? Cracking.

Here's why it happens, with a focus on hot shortness and liquation cracking, plus a few other key culprits.

🔥 1. Hot Shortness – The Brittle Danger Zone

Hot shortness is a condition where aluminum becomes brittle at elevated temperatures, typically just below the melting point. While steels become ductile when heated, aluminum can become brittle in certain heat ranges.

💡 What causes hot shortness?

- Certain aluminum alloys (especially those with high amounts of copper or other alloying elements) form low-melting eutectics along grain boundaries.

- When heated during welding, those eutectics partially melt, weakening the structure.

- As the weld cools and contracts, the weakened grain boundaries crack under stress.

Think of it as if chocolate chips are the glue that holds a cookie together — if the chips melt before the surrounding cookie dough, the cookie falls apart.

2. Liquation Cracking – Heat-Affected Zone Failure

Liquation cracking is a form of hot cracking that occurs in the HAZ (heat-affected zone), not the weld metal itself.

What causes it?

- Some microstructural components (eutectic phases or segregated elements) partially melt in the HAZ.

- These "liquated" regions fail to solidify while under the expansion and contraction stresses from welding.

- As the weld cools and shrinks, cracks form at the grain boundaries where melting occurred.

3. Solidification Cracking (Hot Cracking in Weld Metal)

Cracks that form inside the weld bead during solidification due to:

- Wide freezing range of the alloy or filler

- Poor filler metal choice

- High welding speeds

- Improper joint design or restraint

Common Fix:

less heat input and more filler metal on fillet welds

Use a crack-resistant filler (e.g., ER4043, ER4943 instead of ER5356 for 6061).

4. Cold Cracking (Less Common in Aluminum)

More common in steels, but aluminum can crack after cooling if:

- The weld is highly restrained.

- There are impurities or contamination.

- The base metal was overworked or highly stressed before welding.

Furick 8 pro Etch zone

Ally #5 etch zone